Slicer for door frame board quick forming

A technology of opening machine and door frame plate, which is applied to circular saws, wood processing appliances, sawing components, etc., can solve the problems of unsatisfactory door frame plate production method and non-standard lateral bending of products, and achieves ideal and good structural design. Quality benefit and economic benefit, the effect of guaranteeing straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

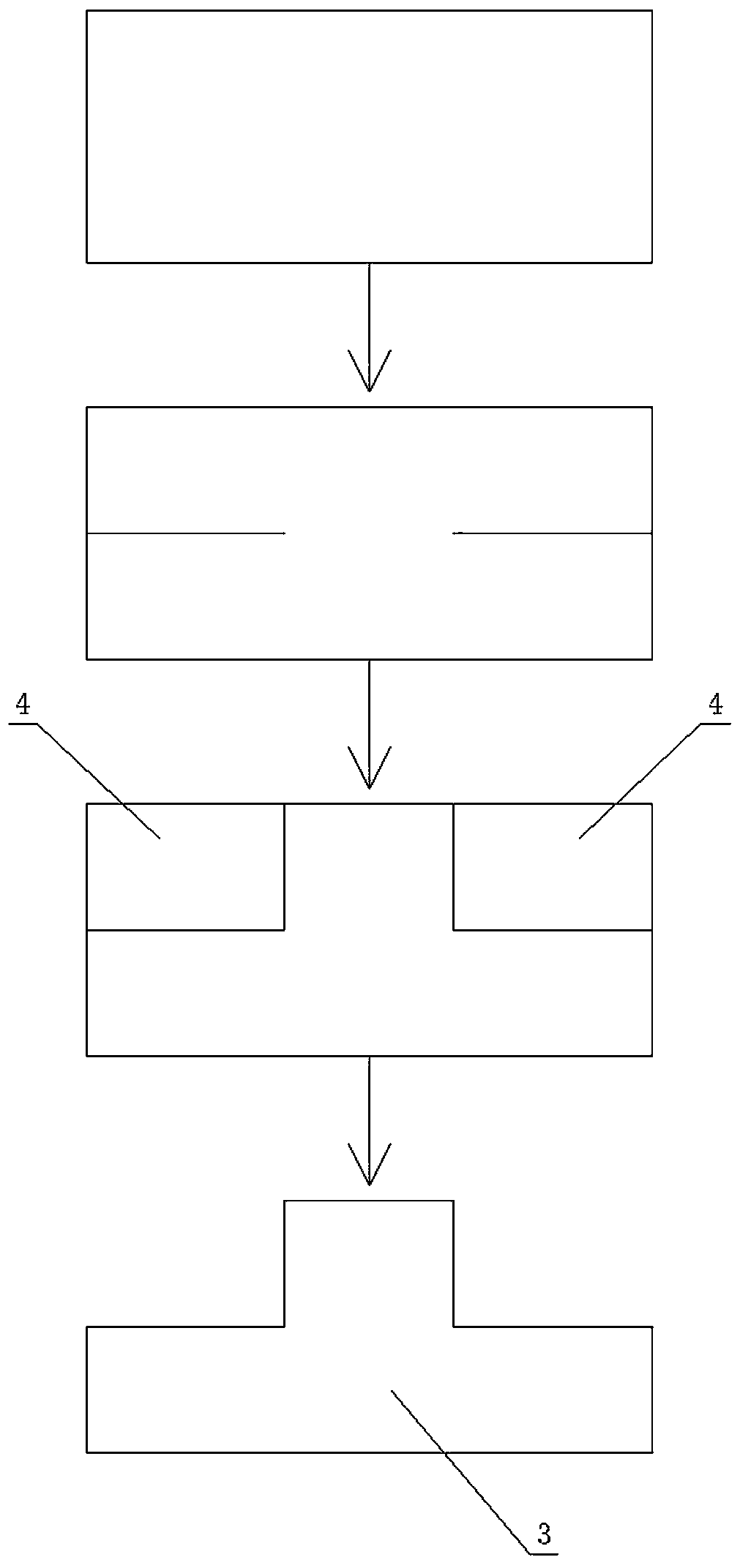

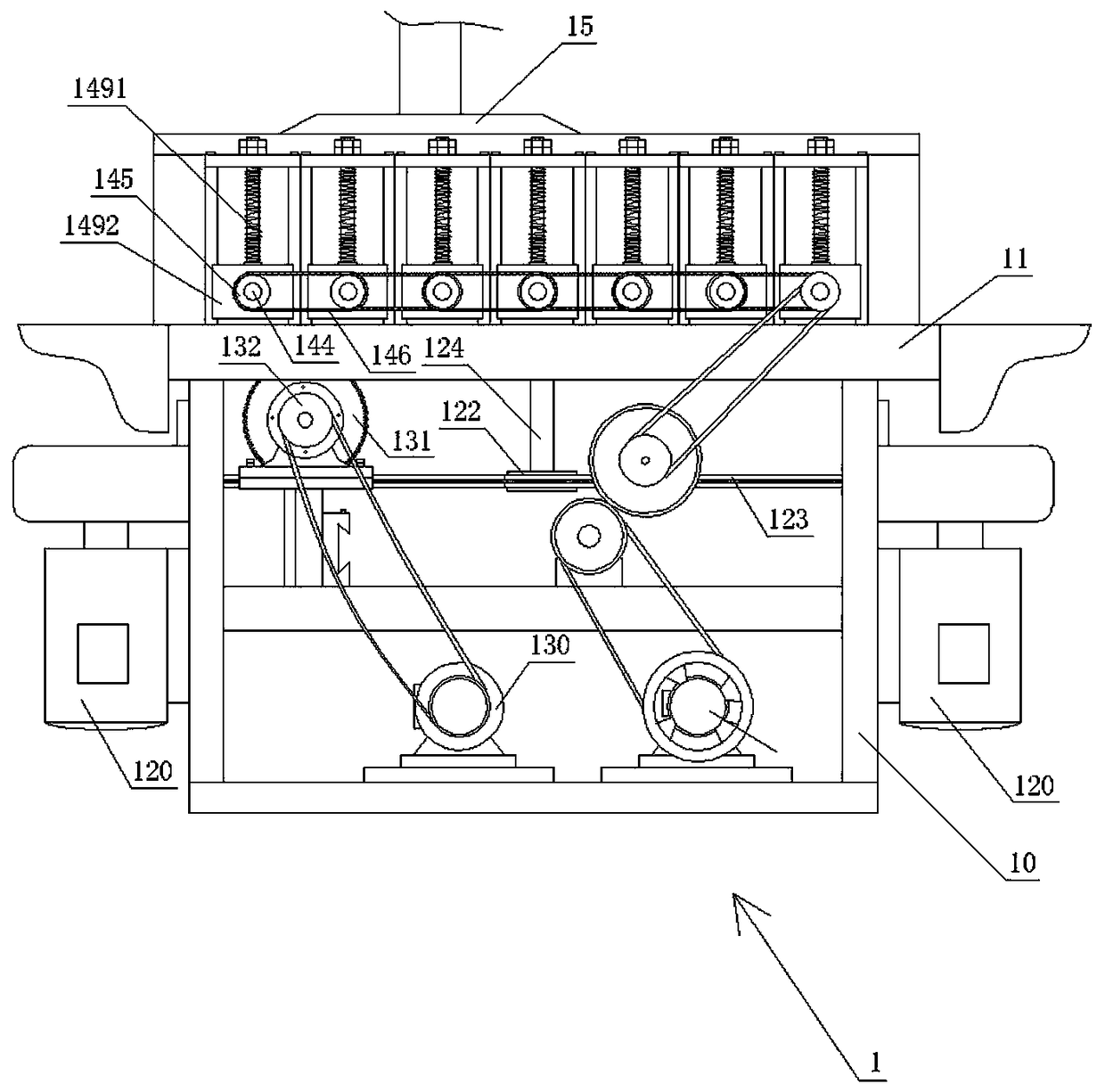

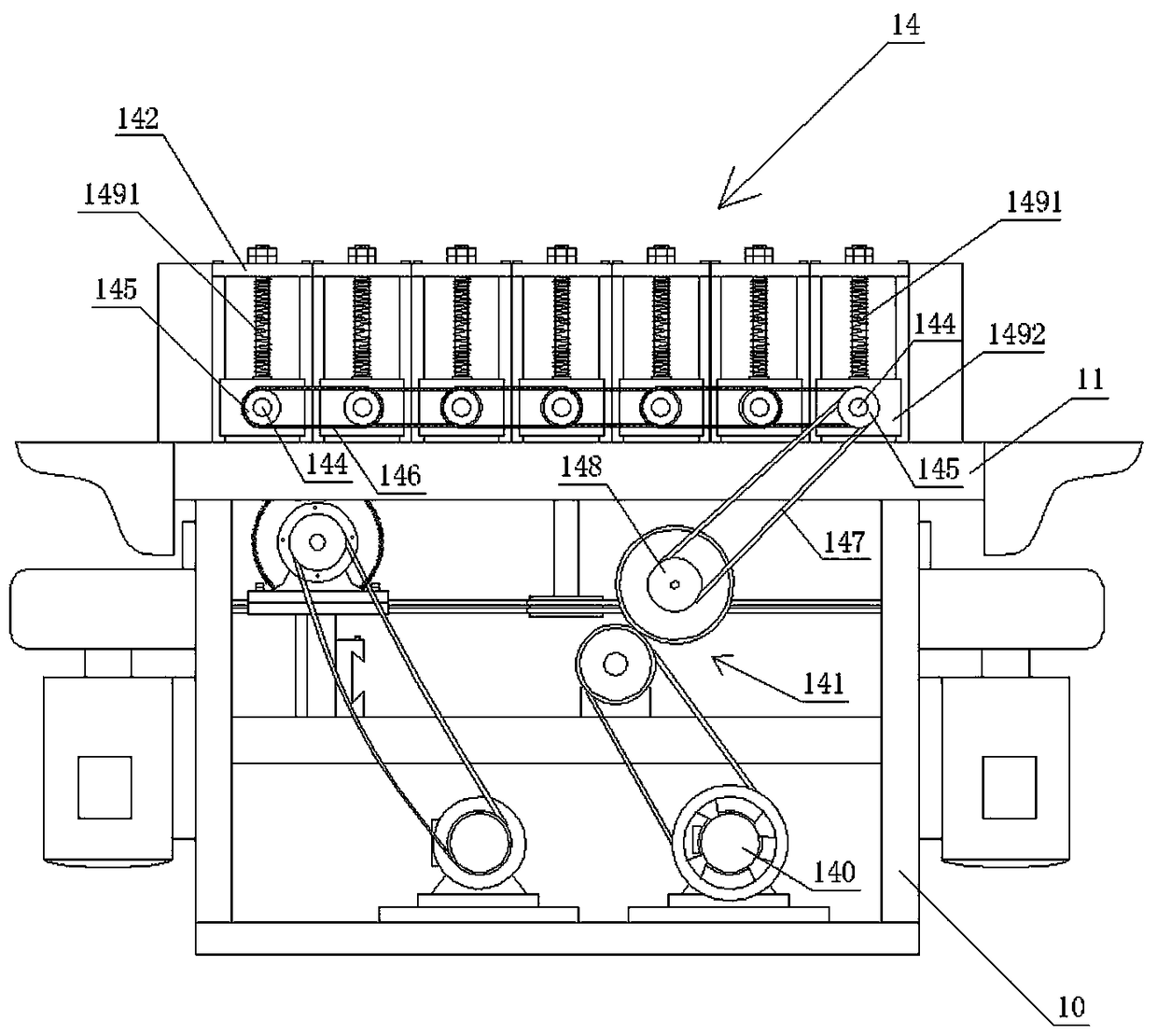

[0023] Refer to attached figure 2 , image 3 , Figure 4 with Image 6 . A sheet opening machine for rapid prototyping of door frame panels includes a frame 10, a working platform 11 mounted on the frame 10, a cross-cutting cutter 12 mounted on the working platform 11 and used for laterally cutting the sides of short materials , be installed on the working platform 11 and be used for the slitting cutter 13 that cuts the same side of short material longitudinally and be installed on the frame 10 and be used for pushing the pushing device 14 that short material moves forward on the working platform. Described frame 10 is also provided with dust removal top cover 15 and dust removal side cover 16, and this dust removal top cover 15 covers and is arranged on the top of work platform 11, and described dust removal side cover 16 covers is located at the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com