Production line for preparing bamboo powder by moso bamboo raw material

A production line, bamboo powder technology, applied in the direction of manufacturing tools, mechanical equipment, sugarcane machining, etc., can solve the problem of unsatisfactory preparation of xylo-oligosaccharide powder, etc., and achieve the effect of ideal structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

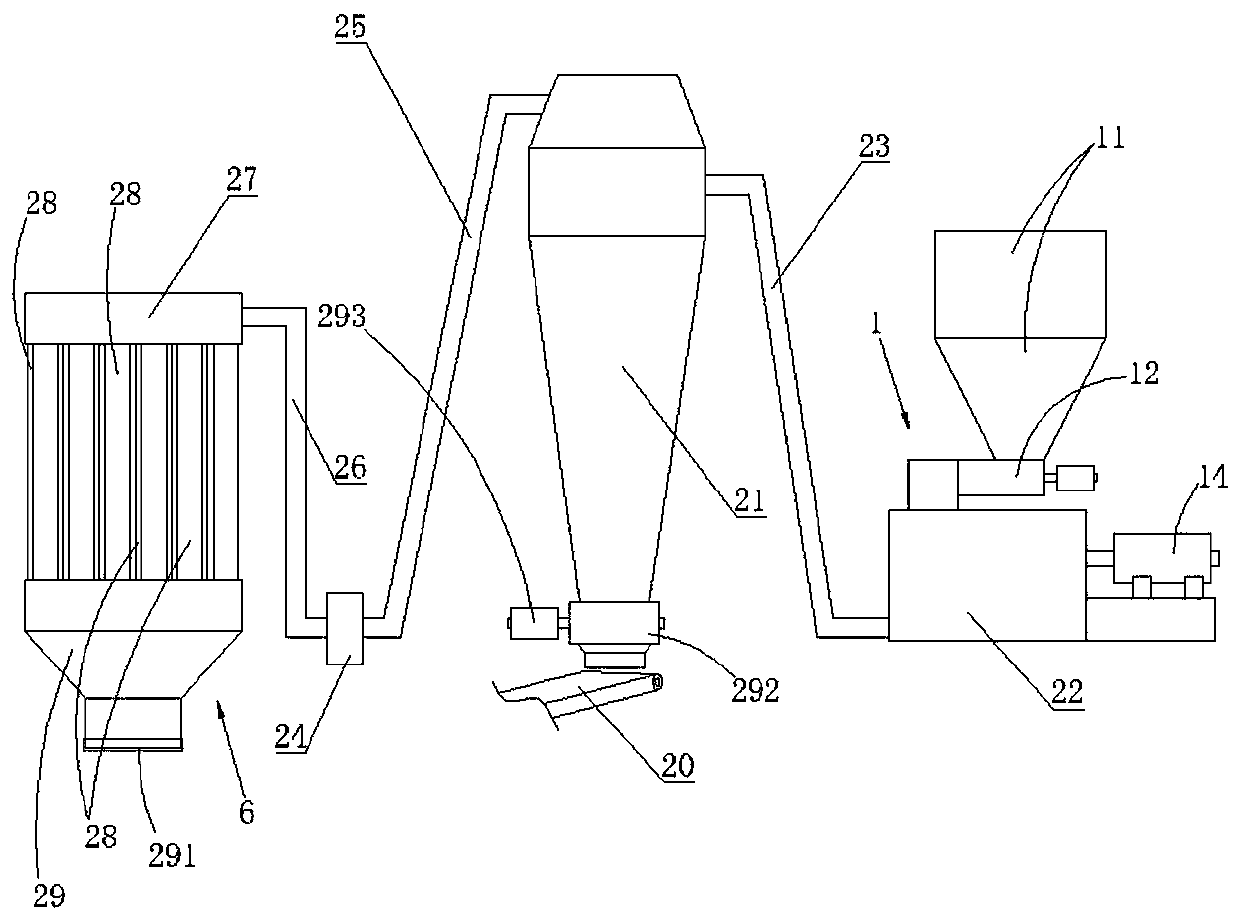

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

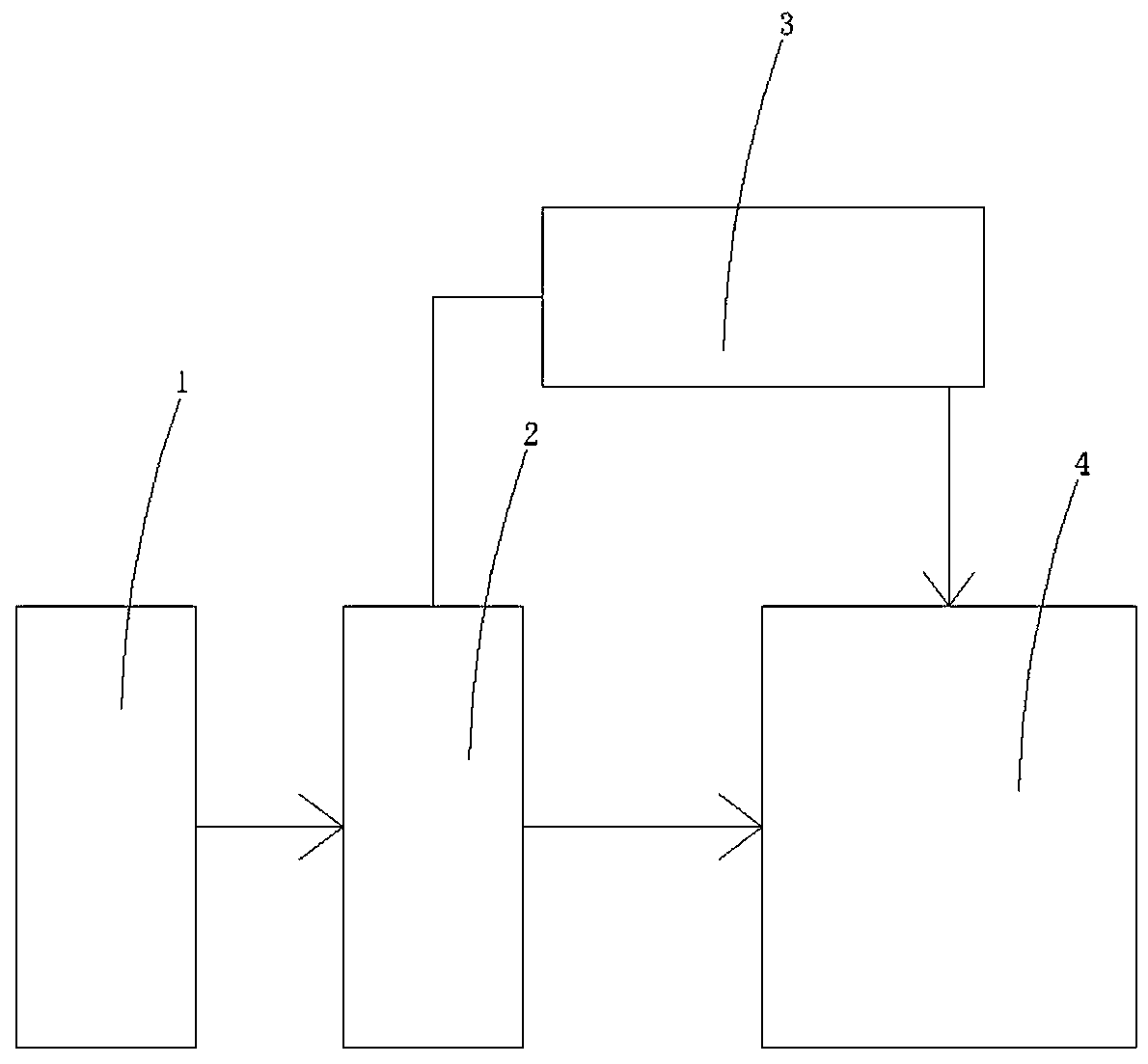

[0024] Refer to attached figure 1 . A kind of production line that mao bamboon raw material prepares bamboo powder, comprises that moso bamboo is cut into the cutting machine 1 of bamboo chip, is used for the crusher 2 that bamboo chip is broken into bamboo powder and is used to collect the bamboo powder collection room 4 of bamboo powder; Also be connected with tumble dryer 3 between crusher 2 and bamboo powder collection room 4.

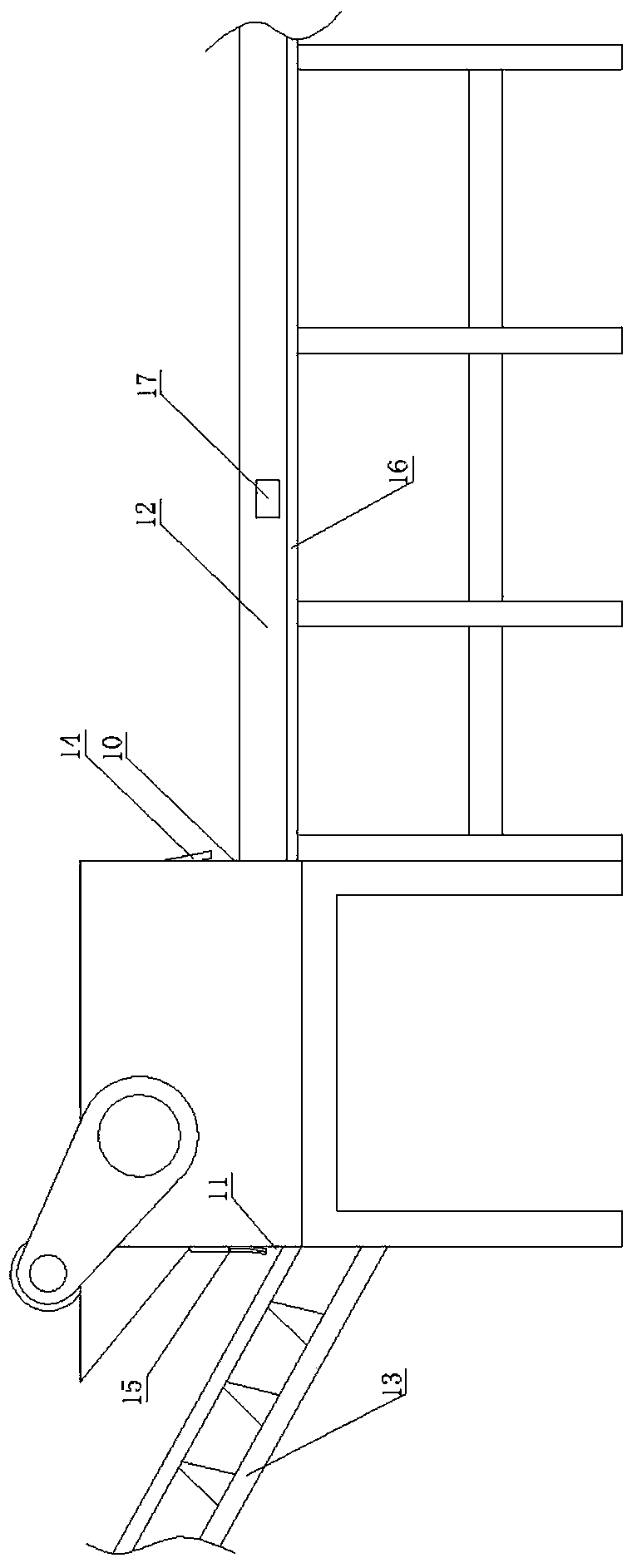

[0025] Refer to attached figure 1 and figure 2 . The cutting machine 1 includes a cutting machine body, the cutting machine body is provided with a feed port 10 and a discharge port 11, wherein the feed port 10 is connected to a first conveyor belt 12, and wherein the discharge port 11 has a second conveyor belt 13 for receiving , the length of the first conveyor belt 12 is 6-8 meters; the feed port 11 is provided with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com