Automatic detection line

An automatic detection and detection area technology, applied in sorting and other directions, can solve the problems of affecting efficiency, increasing labor costs, inability to fully detect defective product marks and isolation, etc., to achieve the effect of reducing costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

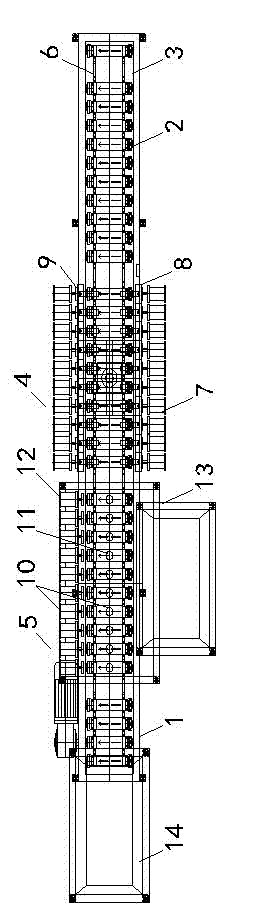

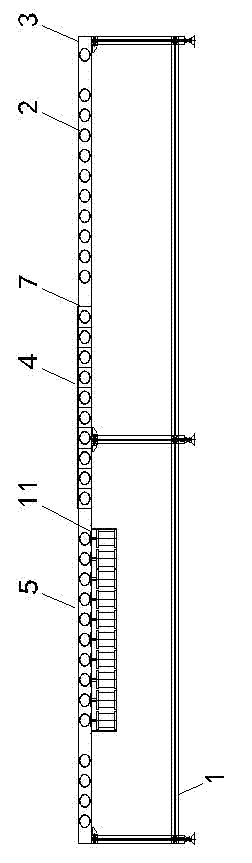

[0015] as attached figure 1 ~2 shows the automatic detection line of the present invention, including: frame 1, parts rack 2; two mutually parallel tracks 3, detection area 4, and selection area 5 are set on the frame 1; A chain 6 is respectively set in the track 3; the two ends of the parts rack 2 are respectively set on the two chains 6 and are perpendicular to the chain 6; the detection area 4 is provided with a cylinder 7; the cylinder 7 is set on two sides of the frame 1 side and opposite to each other, and a clamp 8 is provided on it, and a detection device 9 is provided on the clamp 8; Detect, and make the fixture 8 mark the defective pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com