A kind of automatic manufacturing equipment of refrigerator box shell and refrigerator

A technology for manufacturing equipment and refrigerators, which is applied in the field of automated manufacturing equipment and refrigerators, can solve the problems of low heat exchange efficiency of the box shell, slow production rhythm, and low degree of refinement, and achieves improved heat exchange efficiency, quality, and processing. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0059] The present invention proposes a brand-new automatic manufacturing equipment for the case shell of an electric refrigerator, which changes the traditional case shell structure assembled from multiple boards. Simple, high degree of refinement.

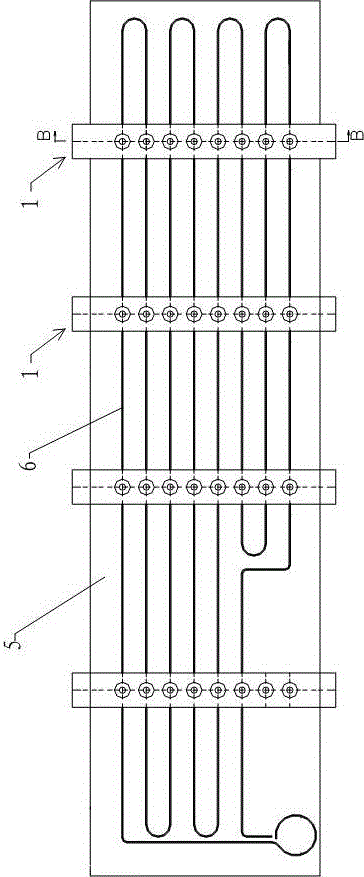

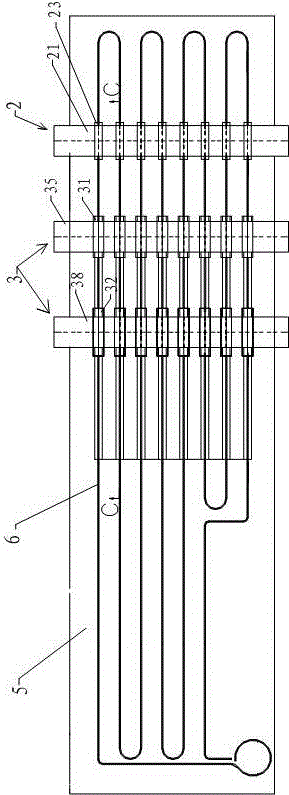

[0060] The automated manufacturing equipment includes blanking dies, folding dies, internal cooling pipe group bending dies, precise positioning and translation fixtures 1, pre-guiding tooling 2, intelligent automatic covering tooling 3, and automatic overall bending dies 4. Among them, the blanking die, the folding die, and the internal cooling pipe group bending die are existing equipment dies, and will not be repeated here.

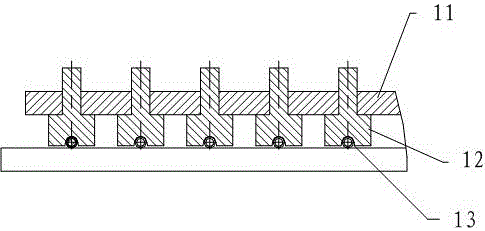

[0061] Such as Figure 1-2 As shown, the precise positioning and translation jig 1 includes a first fixed frame 11, on which the number of clamping parts 12 eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com