A transparent manual clamping support frame for a rectangular tube plate laser cutting machine

A laser cutting machine and transparent technology, applied in the field of support frames, can solve problems such as difficulties in practical application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

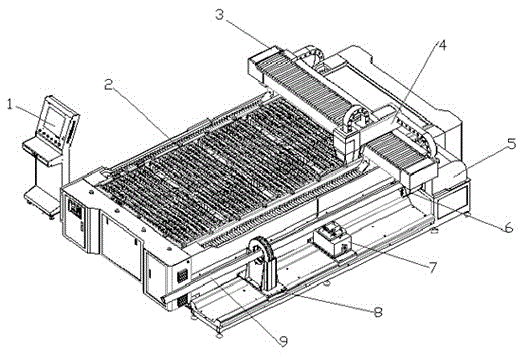

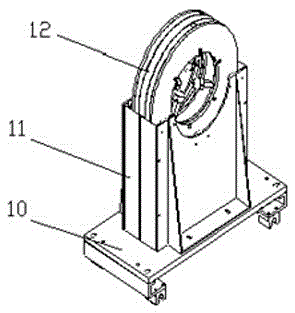

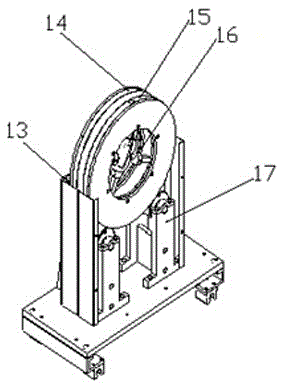

[0012] Such as figure 1 As shown, a transparent manual clamping support frame for a rectangular tube plate laser cutting machine according to an embodiment of the present invention includes a console 1, a plate cutting machine part 2, an extended beam 3, a slide box 4 with a cutting head, and a cutting board. Spindle box of tube machine 5, four-claw pneumatic chuck clamped in pairs 6, round tube adjustable up and down support 7, transparent manual clamping in pairs and axial movement support 8, rectangular tube with cutting 9, adjustable Base for height adjustment 10, front and rear positioning plates 11, transparent manual two-two clamping support frame 12, axially positioned bull's-eye 13, manual clamping disc A14, manual clamping disc B15, two-two clamp with bull's-eye Tight top column 16, supporting roller frame 17, described con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com