Anti-falling device for coated workshop gate

An anti-fall, workshop technology, applied in door/window protection devices, windows/doors, door/window accessories, etc., can solve problems such as structural deformation of the bottom of the lower chord, to extend the service life, avoid deformation, and prevent the door from falling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

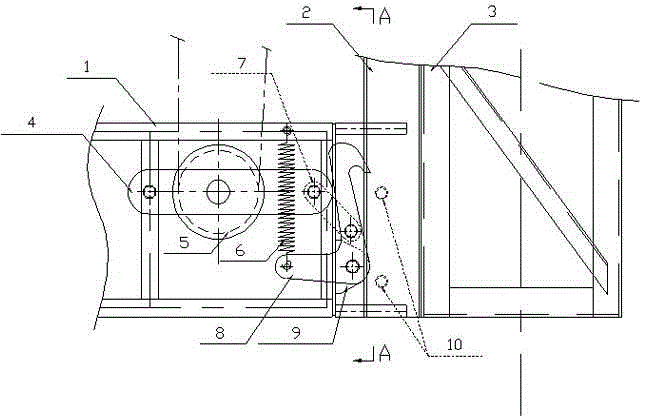

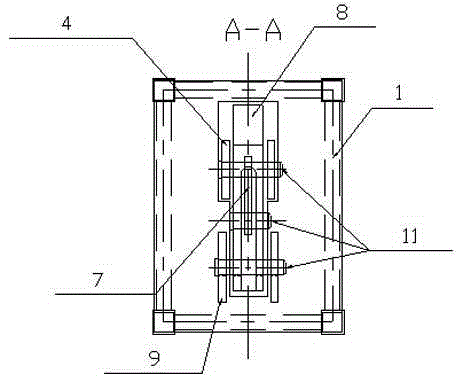

[0011] Such as figure 1 , figure 2 It can be seen from the schematic diagram that the anti-falling device for the painting workshop gate of the present invention includes a column 3, a slideway 2, a lower chord 1, a lifting wheel 5, an anti-falling plate 10, a spring 6 and a connecting push rod 7.

[0012] The lower chord 1, the slide 2 and the upright 3 are distributed from left to right. The slide 2 is installed at the side end of the pillar 3. The lower chord 1 can move up and down along the extension direction of the slide 2, and the lifting wheel 5 , The anti-falling plate 10, the spring 6 and the connecting push rod 7 are all installed on the lower chord 1. There are several anti-falling rods 10, which are evenly distributed on the slideway 2, and the anti-falling rods 10 and the slideway 2 are mutually perpendicular to each other.

[0013] There is a lifting wheel fixing plate 4 on both sides of the lifting wheel 5, and both sides of the lifting wheel 5 are respectively mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com