Multi-stage tube depth sampling device

A sampling device and multi-stage tube technology, which is applied in the field of multi-stage tube depth sampling device, can solve the problems of accurate sampling, danger, and the failure of the sampling head to reach the specified depth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

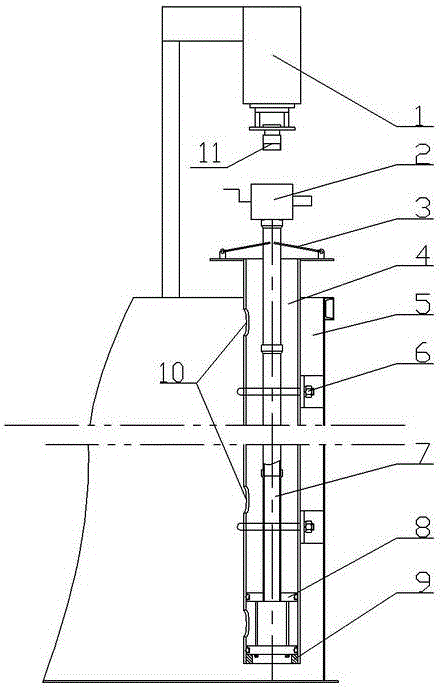

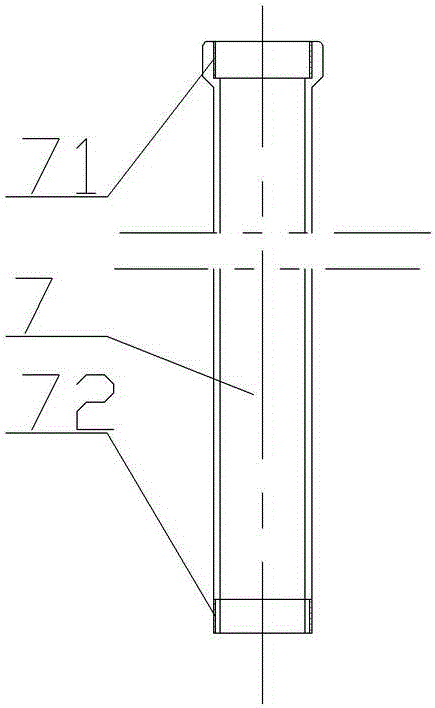

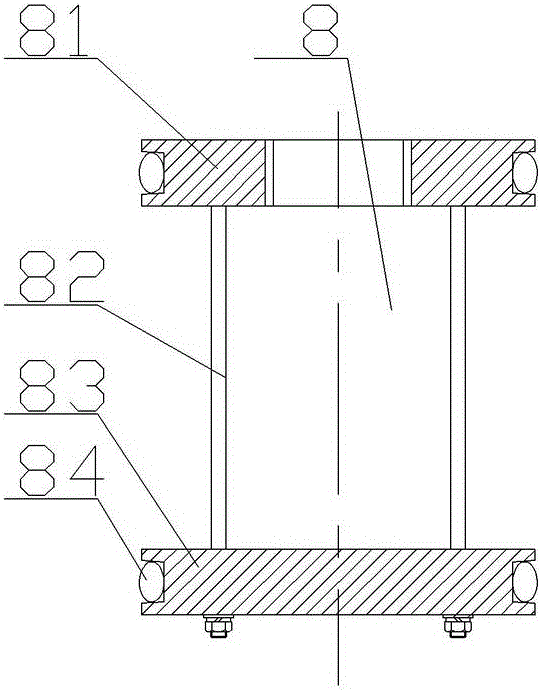

[0017] see figure 1 , figure 2 with image 3 As shown, the present invention is composed of a multistage telescopic hydraulic device 1, a hand pump 2, a pipeline chuck 3, a sampling main pipe 4, a tank body 5, a U-shaped bolt 6, a multistage guide tube 7 and a sampling head 8. The above-described sampling main pipe 4 is fixed on the wall of the tank body 5 through U-shaped bolts 6; the sampling head 8 is movably installed inside the sampling main pipe 4, and is threadedly connected with the multi-stage draft pipes 7, and the multi-stage draft pipes 7 are also threaded. Through threaded connection, the pipe chuck 3 is set on the top of the sampling main pipe 4 and clamps the multi-stage guide tube 7; the hand pump 2 is fixed on the multi-stage guide tube 7 by threaded connection; Shake the specified distance directly above pump 2.

[0018] The multi-stage telescopic hydraulic device 1 is equipped with a threaded joint 11 for connection, and the threaded joint 11 is used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com