Refrigerator door body shaping mold

A refrigerator door and forming mold technology, which is applied in the field of refrigerator door forming molds, can solve problems affecting the appearance of the refrigerator door, burrs and joint marks on the parting line, and splashing of raw materials, etc., and achieve the effect of improving the appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

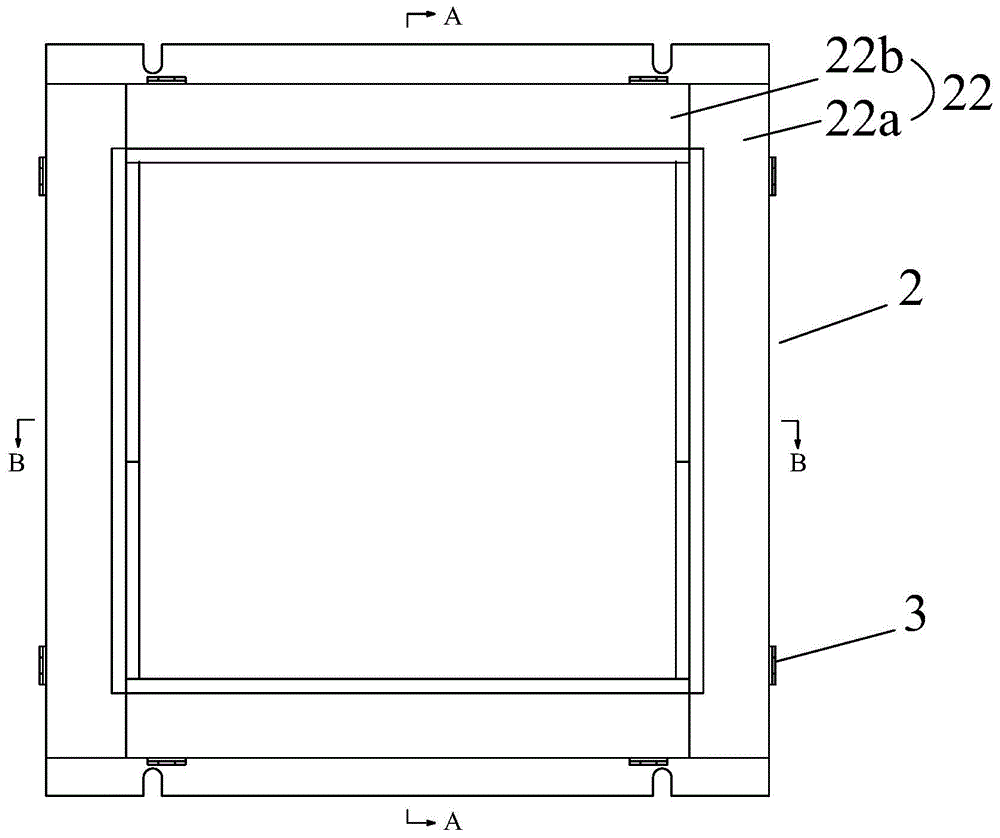

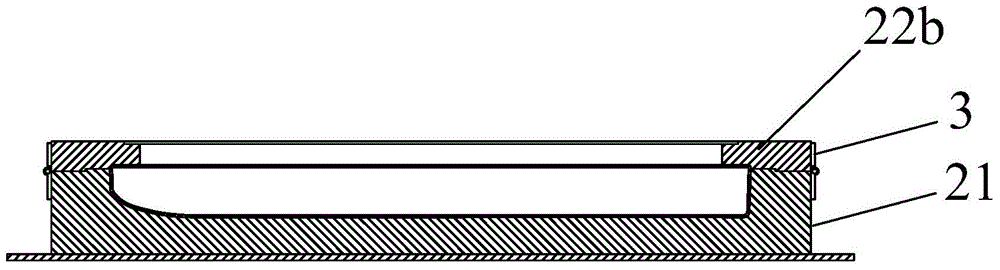

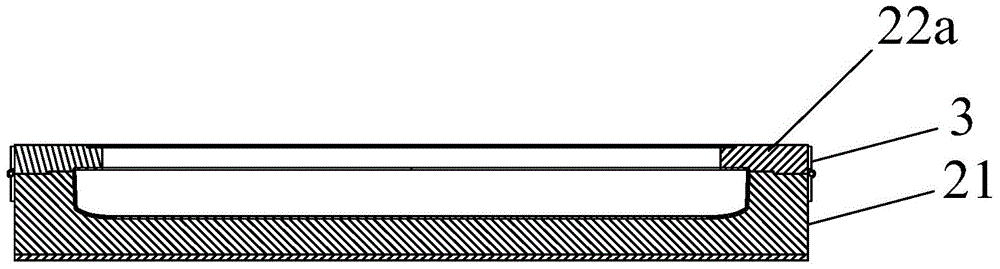

[0027] Refer below Figure 1 to Figure 9 The specific implementation of the refrigerator door forming mold according to the present invention will be described in detail.

[0028] In this example, if Figure 8 and Figure 9 As shown, the door shell 1 of the refrigerator door body mainly includes a square thin plate-shaped part 1a (constituting the main body of the door shell), on the inner surface of the thin plate-shaped part 1a, it is integrally formed along its surrounding edges and perpendicular to the thin plate-shaped part 1a. The second hem portion 12 and the first hem portion 11 vertically connected with the second hem portion 12 and parallel to the thin plate-shaped part 1a, so that an inverted L is formed on the inner surface of the door case 1 along its peripheral edge. Shaped hem, as in Figure 9 As shown, the L-shaped horizontal part is formed by the first hemming part 11, and the L-shaped vertical part is formed by the second hemming part 12, and the symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com