Quick disassembling mechanism for driving plate of packaging equipment

A kind of packaging equipment, fast technology, applied in the field of dial components, can solve the problems of long disassembly process and affecting the production efficiency of equipment, and achieve the effect of convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

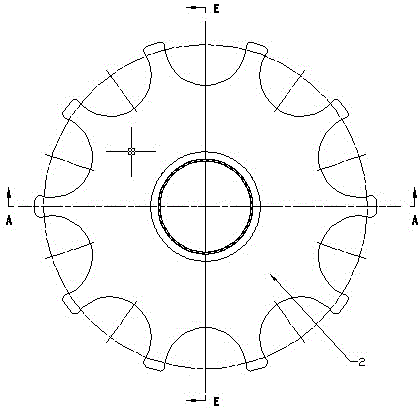

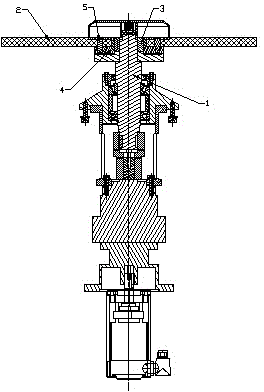

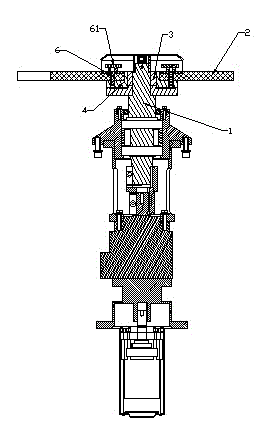

[0012] As shown in the figure, the dial quick disassembly mechanism of the packaging equipment includes a vertical drive shaft 1 and a dial 2 mounted on the drive shaft; the upper end of the drive shaft is fixedly connected to a connecting plate 4 through an expansion sleeve 3, so The inner ring of the dial 2 falls on the connecting plate 4, and the positioning pin 5 is passed between the dial 2 and the connecting plate 4 and connected by a screw 6. The screw 6 passes through the dial 2 from above and is threadedly connected with the connection plate 4, and the upper end of the screw is provided with a manual knob 61, so as to facilitate manual disassembly. The pin hole on the locating pin 5 upper end is tightly matched with the dial, and the pin hole clearance fit on the locating pin lower end on the connection plate. A pair of positioning pins and screws are arranged respectively, and they are distributed in a cross shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com