Steel-aluminum alloy cage

An aluminum alloy and cage technology, which is used in transportation and packaging, lifting equipment in mines, etc., can solve the problems of high energy consumption, heavy equipment, and cumbersome cages, saving power, improving mining efficiency, Scientific and rational effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

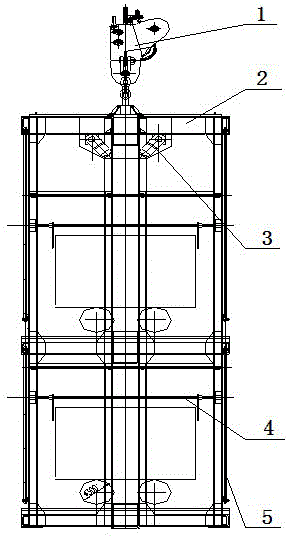

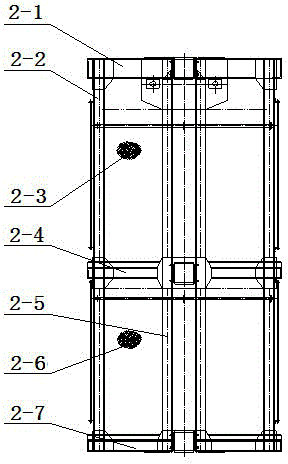

[0015] The specific embodiments of the present invention are given below with reference to the accompanying drawings, which are used to further describe the structure of the present invention.

[0016] The steel-aluminum alloy cage of the present embodiment comprises a cage body 2, a suspension device 1 connected with the cage body by a wire rope, a safety door 5 and a car stop device 4 are installed on the cage body, and a safety device 3 is installed on the top of the cage body.

[0017] The car stop device is the positioning device of the mine car, which prevents the mine car from slipping out of the cage during the lifting process, causing accidents. The safety device is the anti-fall arresting part of the entire cage. Normally, the device is in the open state during the operation of the cage. Once the wire rope breaks and an accident occurs, the cage will fall, and the safety device will automatically close at this time. The catcher Carry out the catching action, and fix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com