New low-concentration coalbed methane or gas steam boiler

A steam boiler, low-concentration technology, applied in water-tube steam boilers, steam boilers, boiler water pipes, etc., can solve the problems of not being able to directly install low-gas burners, and achieve good energy-saving and emission-reducing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

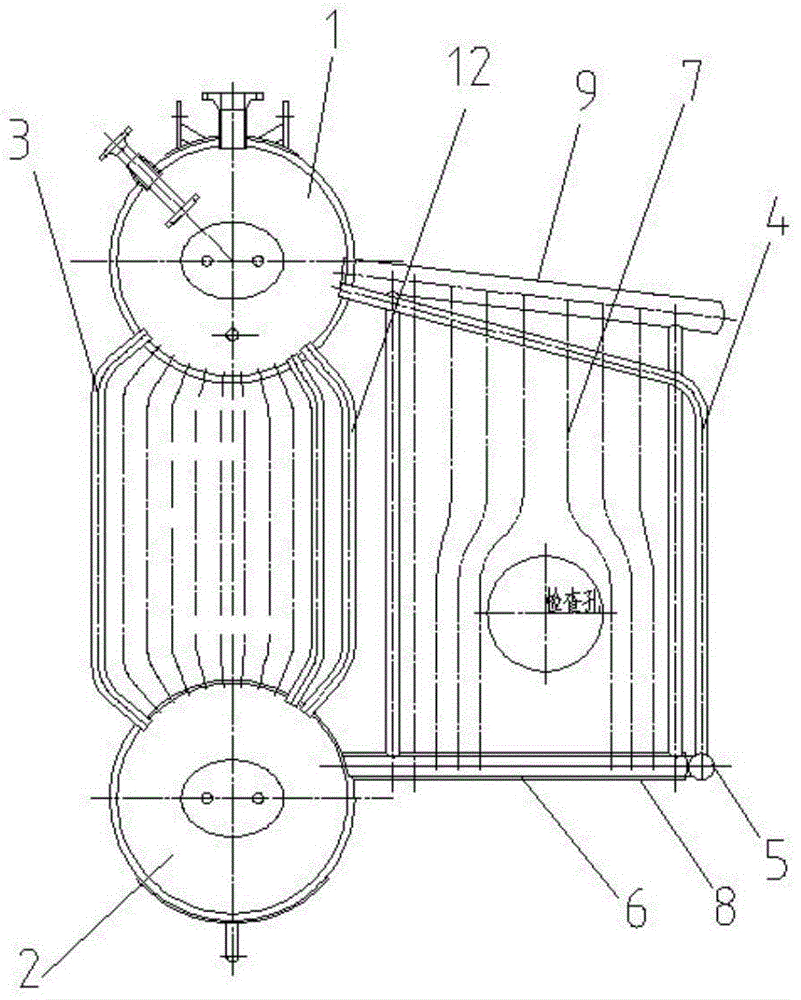

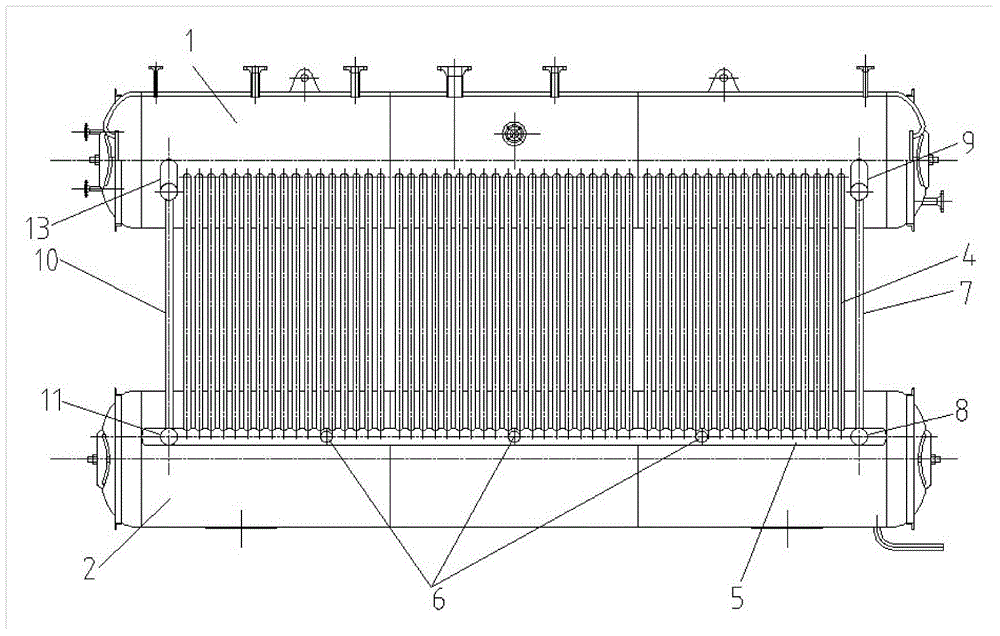

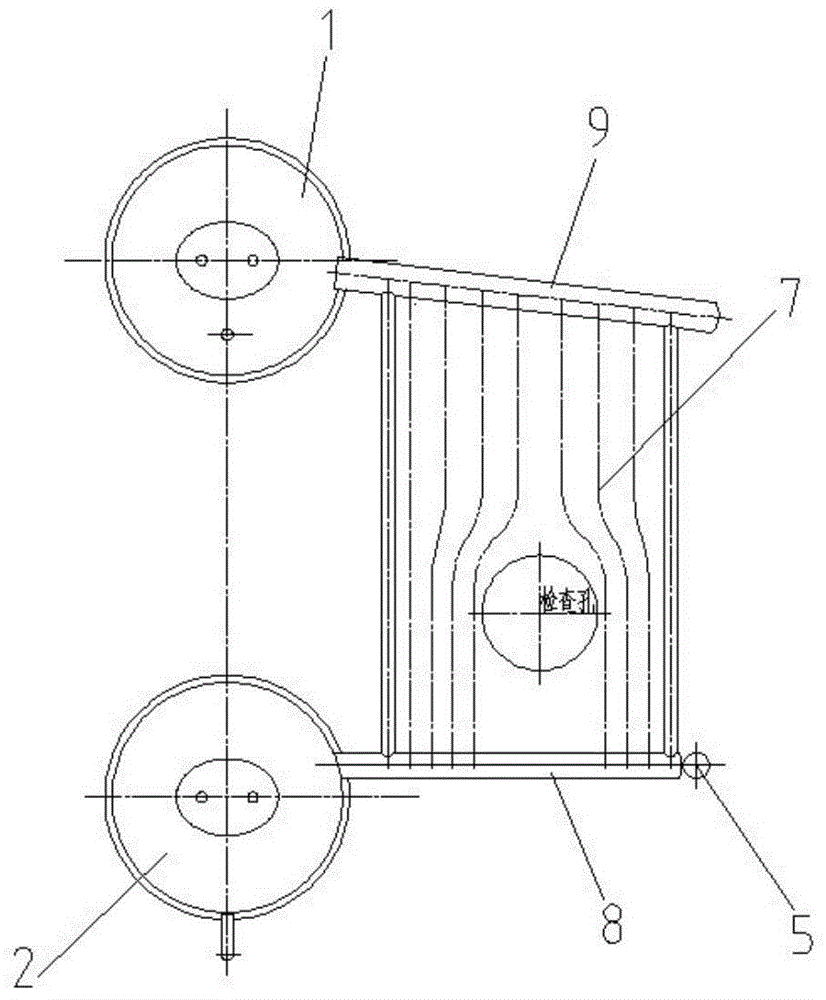

[0024] The present invention as Figure 1 to Figure 5 As shown, the boiler body is a double-drum vertical D-type boiler, including an upper drum 1 and a lower drum 2. The lower part of the outer wall water-cooled wall 4 is vertically connected with the lower header 5 of the outer wall water-cooled wall. The outer wall water-cooled wall 4. The upper part is inclined and bent upwards to connect with the upper drum 1. In order to ensure good hydrodynamic characteristics in the water-cooled wall 4 of the outer wall, the lower header 5 of the water-cooled wall of the outer wall and the lower drum 2 are connected by three connecting pipes 6. This part The water circulation method is: upper drum 1-lower drum 2-communicating pipe 6-outer wall water cooling wall lower header 5-outer water cooling wall 4-upper drum 1, thus forming a complete water circ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap