Printer with temperature detection and efficient heat dissipation functions

A technology for temperature detectors and printers, applied in printing devices, printing, etc., can solve the problems of poor heat dissipation, affecting the printing quality and service life of the printer, and the printer has no internal temperature detection function, so as to ensure the printing quality and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

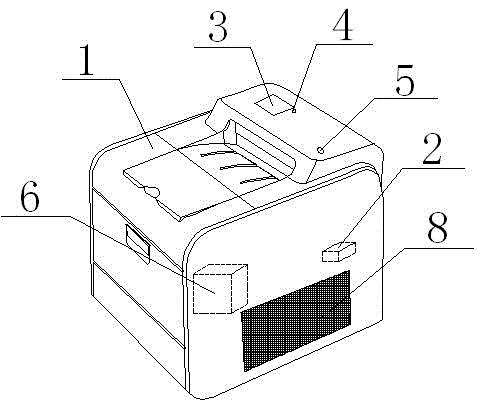

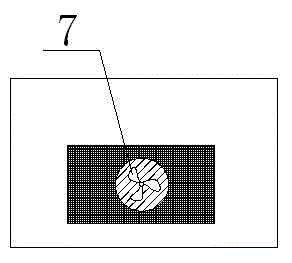

[0016] In order to overcome the defects that the existing printer has no internal temperature detection function and the heat dissipation effect is not good, which affects the printing quality and service life of the printer, the present invention provides a figure 1 The shown printer with temperature detection and high-efficiency heat dissipation functions includes a printer casing 1, and a temperature detector 2 is arranged next to the heating component inside the printer casing 1, and the temperature detector 2 is connected in series to the power supply of the printer In the circuit, the upper surface of the printer casing 1 is provided with a temperature display screen 3, an indicator light 4 and a control switch 5, and the temperature display screen 3, the indicator light 4 and the control switch 5 are connected in series with the temperature detector 2, so that The two sides of the printer housing 1 are provided with heat dissipation nets 8, the interior of the printer ho...

Embodiment 2

[0019] On the basis of Embodiment 1, a layer of sound-absorbing panels is provided inside the left and right sides of the printer casing 1, so that no noise pollution will be generated when the small fan 7 is used to dissipate heat; the temperature detector 2 is placed in the printer Next to the heating element, the heat generated by the heating element is large, which can more accurately detect the internal temperature of the printer and effectively protect other components inside the printer; When inside, the indicator light 4 is green, and when the internal temperature is too high, the indicator light 4 turns from green to red, giving a warning; the distance between the small fan 7 and the cooling net 8 is 5mm, which is conducive to the internal air circulation , better heat dissipation; the heat dissipation net 8 is a detachable structure, which is convenient for cleaning the dust on the heat dissipation net 8 and the small fan 7, and improves the heat dissipation effect. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com