Drip element sealing device, in particular for rolling bearings

一种滚动轴承、密封装置的技术,应用在发动机的密封、轴承组装、球轴承等方向,能够解决尺寸大、高摩擦、低摩擦等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

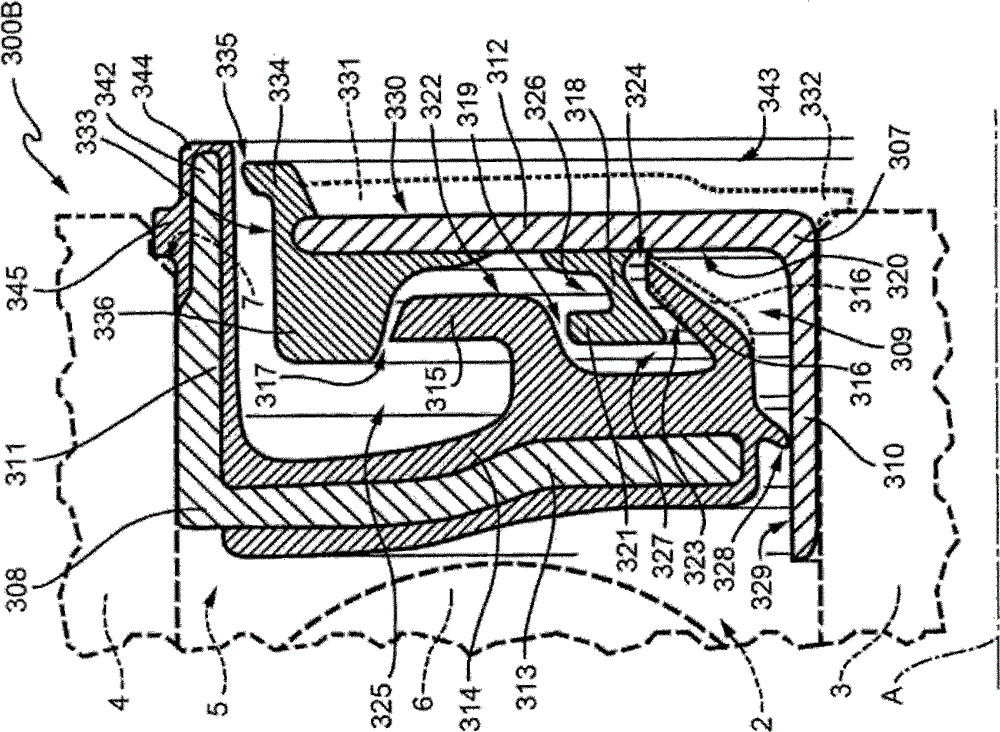

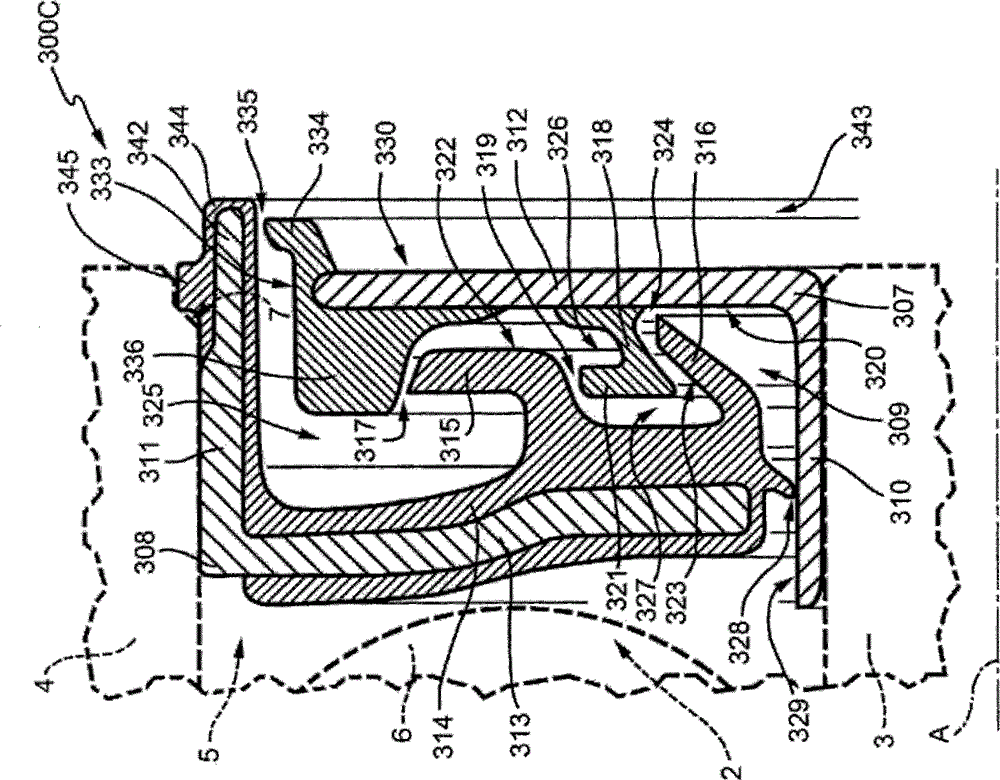

[0009] refer to figure 1 and 2 , reference number 300 ( figure 1 ) denotes a drop-type element seal, in particular it is designed to be mounted on a rolling bearing 2 of a hub assembly, which is known and not shown for the sake of clarity, and which is inserted in relative rotation between the first member 3 and the second member 4 , in the example defined by the inner ring 3 and the outer ring 4 of the bearing 2, for fluid-tight isolation from the external environment, which is indicated by the letter "E", an annular cavity 5 is defined between the members 3 and 4, and As shown in the example, it accommodates a plurality of rolling elements 6 of the bearing 2 .

[0010] According to the first embodiment implemented as figure 1 The sealing device 300 shown, which is represented by the reference numeral 300B, and in figure 2 The second embodiment in is shown by reference numeral 300C.

[0011] For the sake of simplicity, the parts common to the two sealing devices 300B an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com