Installations including steam turbine modules for optimized efficiency

A technology of steam turbines and turbines, which is applied in the direction of steam engine devices, mechanical equipment, engine components, etc., and can solve the problem of low-pressure modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

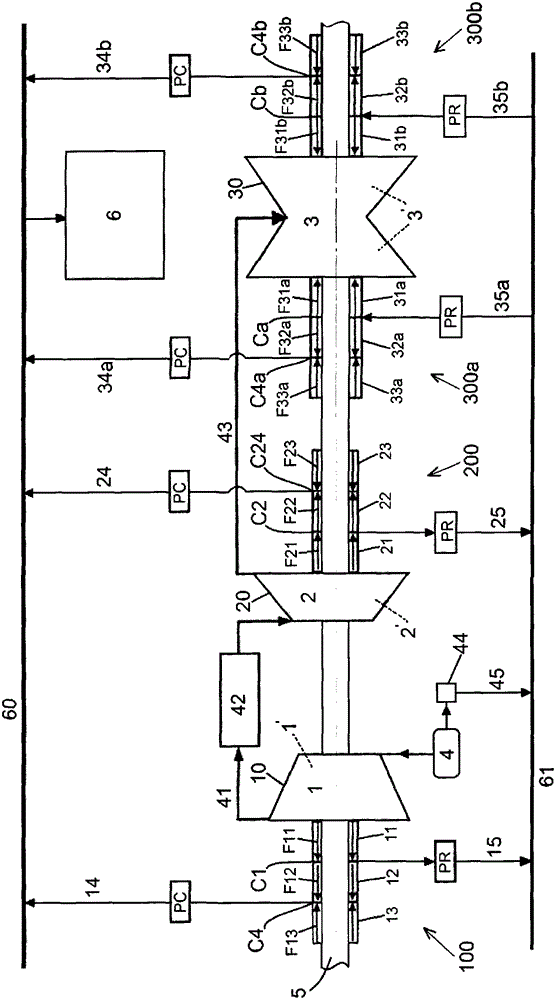

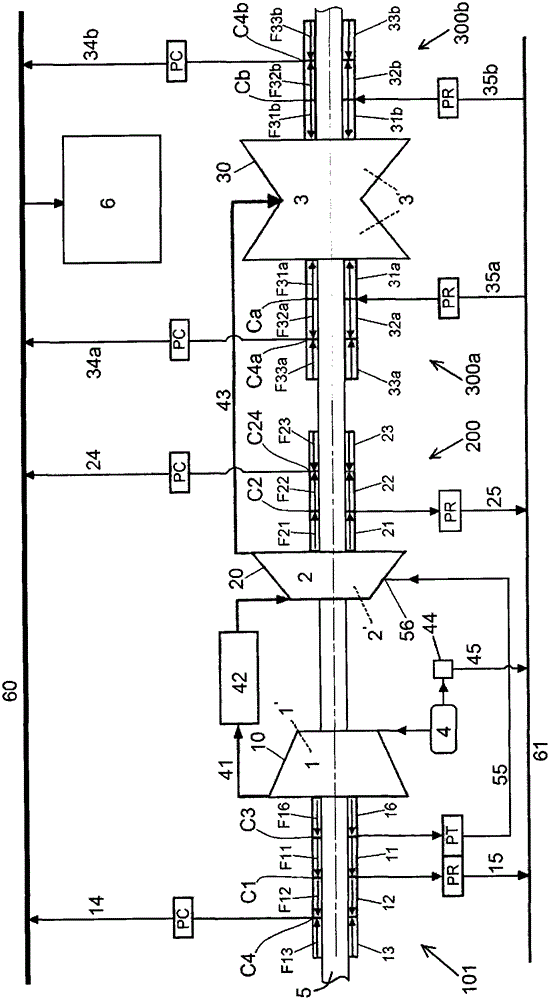

[0018] figure 1 The device according to the invention is shown with its steam circuit. The installation comprises a high pressure steam turbine module 1 , an intermediate pressure steam turbine module 2 and one or more low pressure steam turbine modules 3 . The high-pressure turbine is supplied with live steam, in other words with steam from a steam generator 4, for example a nuclear steam generator. The steam leaving the high pressure module 1 is directed by a conduit 41 through a dryer / superheater 42 towards the inlet of the medium pressure module 2 . The steam leaving the medium pressure module 2 is directed towards the inlet of the low pressure module 3 by a conduit 43 . The port of the low pressure module 3 is connected to a steam condenser 6 .

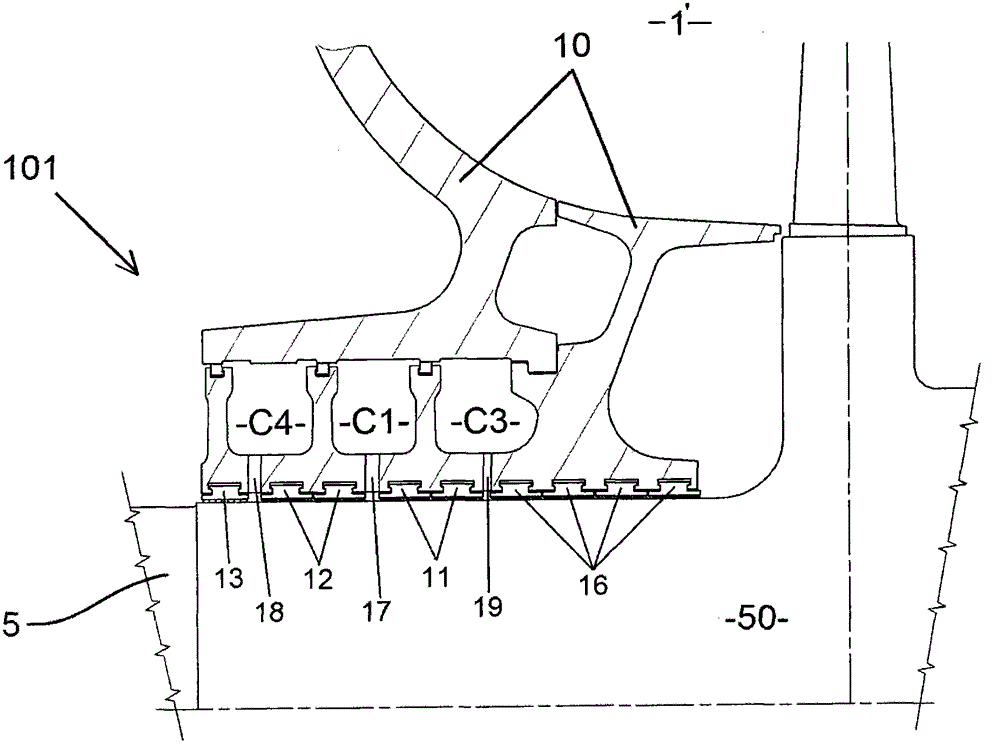

[0019] The rotors of the different modules 1 , 2 , 3 are interconnected to form a rotating turbine shaft 5 . Each rotor is housed in a housing 10 , 20 , 30 belonging to a respective module 1 , 2 , 3 and more precisely in a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com