Four-column hydraulic press

A technology of hydraulic presses and articulated arms, applied in the field of four-column hydraulic presses, can solve problems such as unbalanced pressure, achieve the effects of reducing manufacturing costs and use costs, and achieving high balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

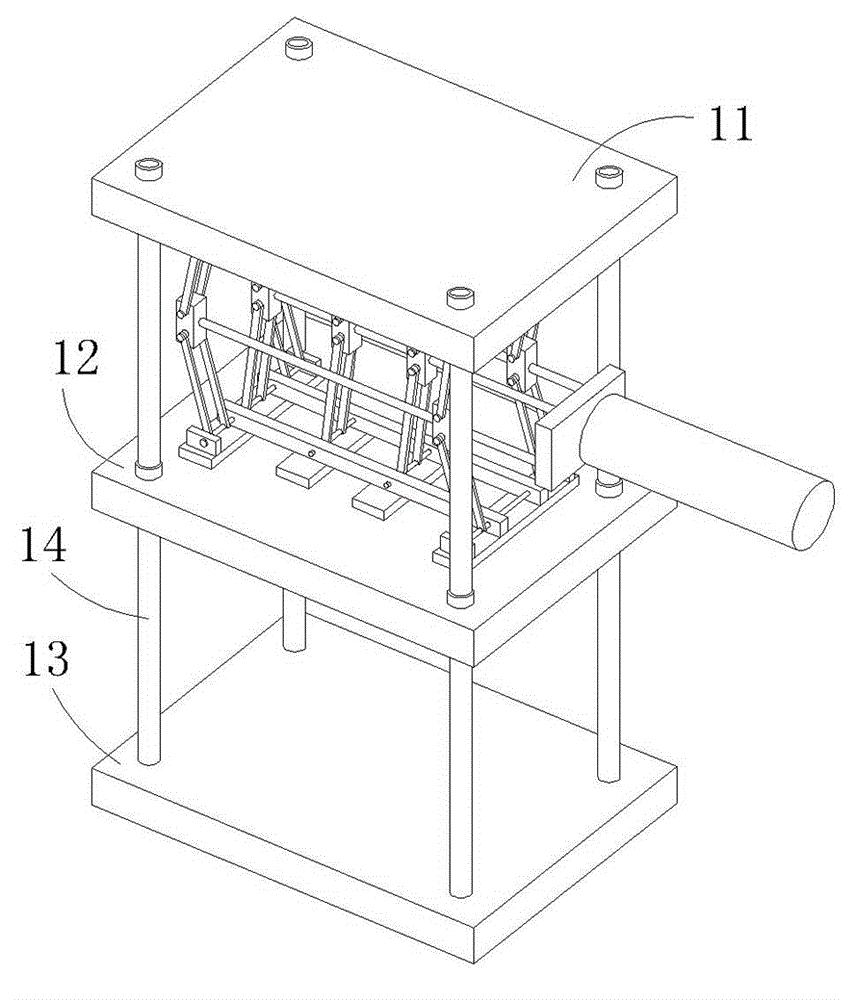

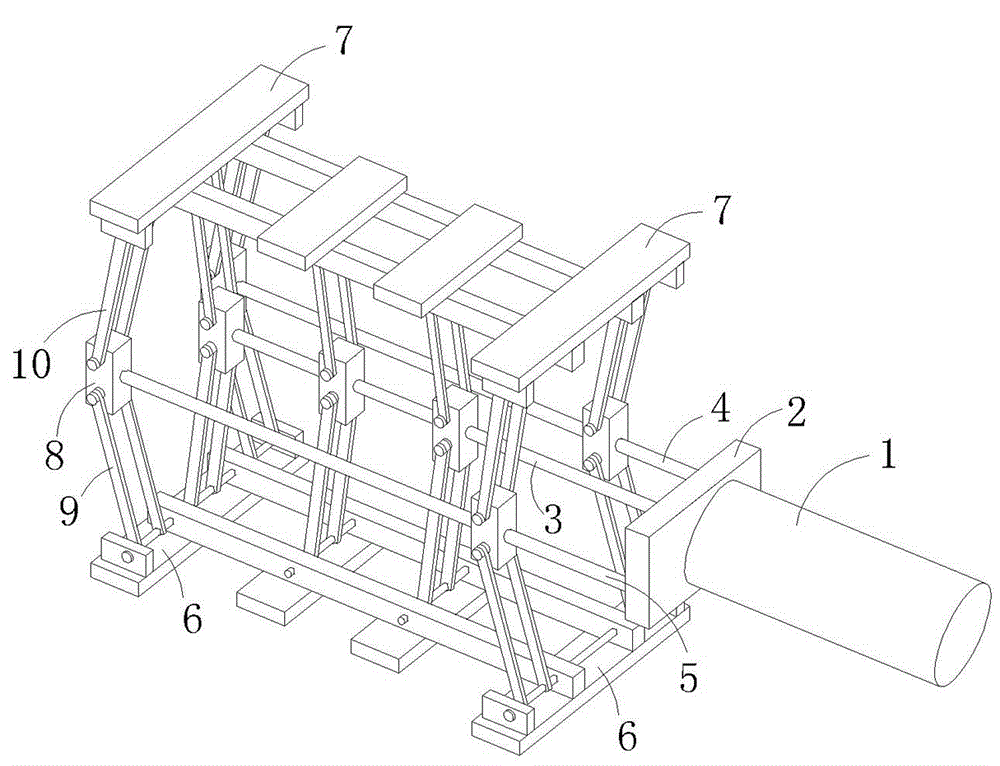

[0010] Such as figure 1 As shown, the four-column hydraulic press includes an upper fixed plate 11, a lower fixed plate 13, and a movable plate 12. The upper fixed plate 11 and the lower fixed plate 13 are fixedly connected by four columns 14, and the movable plate 12 is located between the upper and lower fixed plates 11, 13. and can slide up and down along the column 14, these are all prior art; in addition, the hydraulic machine also includes an oil cylinder 1 and a transmission mechanism, the transmission mechanism is installed between the upper fixed plate 11 and the movable plate 12, through the output of the oil cylinder 1, The transmission mechanism can drive the movable plate 12 to move up and down, thereby exerting pressure on the workpiece located between the movable plate 12 and the lower fixed plate 13 .

[0011] The transmission mechanism includes upper and lower transmission plates 7, 6 (the upper and lower transmission plates 7, 6 are fixedly connected to the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com