Flange assembly suitable for flue pipe connection

A flue pipe and flange technology, which is applied in the field of pipe connection devices, can solve the problems of non-metallic expansion joints that affect the sealing performance, poor versatility, and increased deformation, and achieve the effects of improving assembly efficiency, facilitating replacement and maintenance, and eliminating deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing of description, the present invention will be further described.

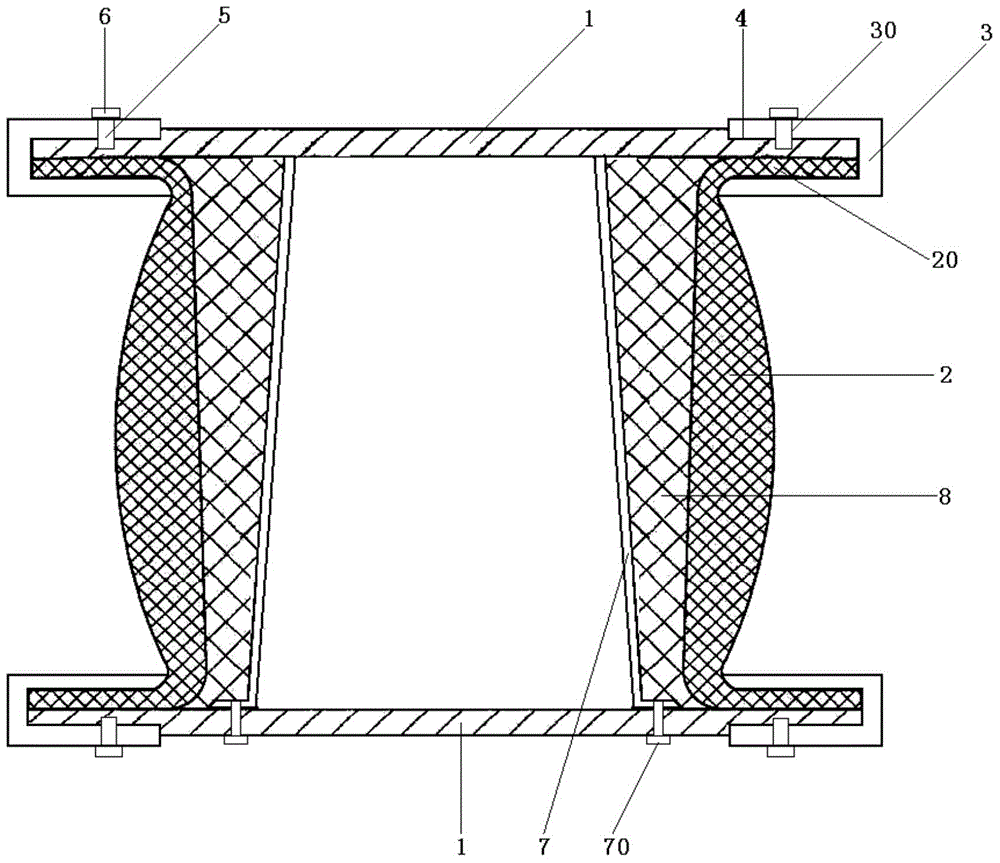

[0024] Such as figure 1 and figure 2 As shown, a flange assembly suitable for the connection of flue pipes includes a pair of flanges 1 connected to the flue pipe 10, a non-metallic expansion joint body 2 arranged between the pair of flanges 1, And the side buckle-type pressure block 3 for snap-fitting the flange 20 of the non-metallic expansion joint body 2 and the flange 1 respectively.

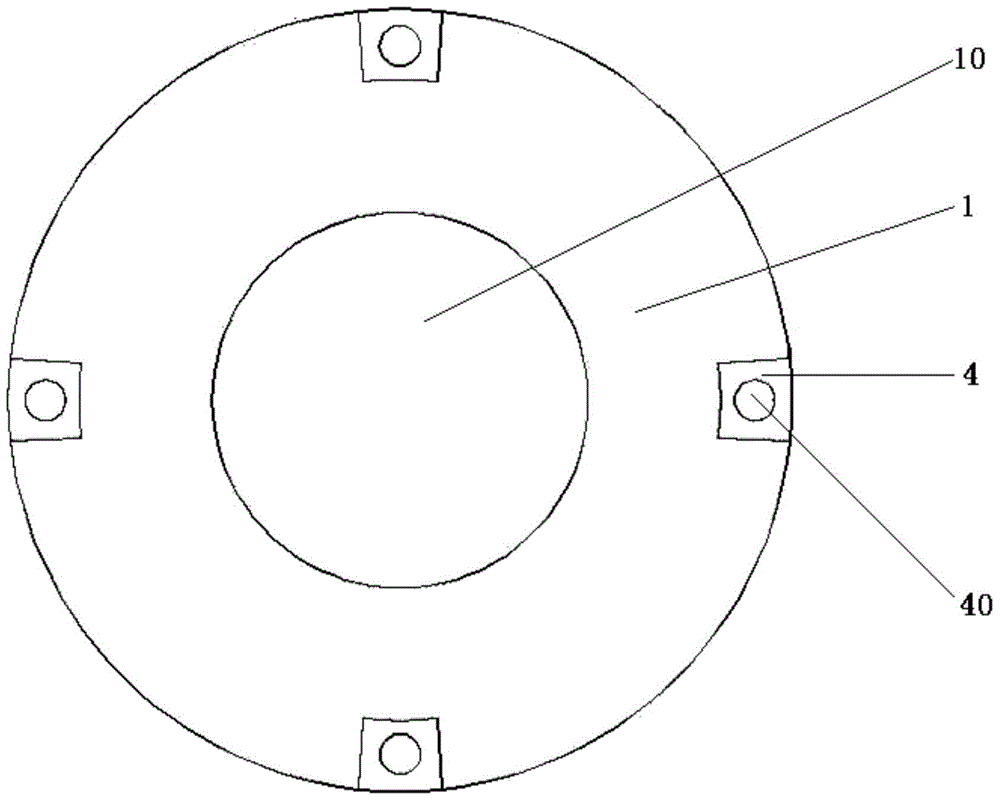

[0025] The peripheral edge of the flange 1 facing the outer surface is provided with a pair of evenly distributed notch grooves 4, such as figure 2 As shown, there are four gap grooves 4 provided by each flange 1, and the first screw holes 40 are arranged in the gap grooves 4; equal, and are provided with the second screw hole 30 corresponding to the first screw hole 40, the pressure block 3 passes through the first screw hole 40 and the second screw hole 30 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com