Pipe flange

A pipeline flange and pipeline technology, which is applied in the direction of flange connection, pipe/pipe joint/pipe fitting, passing components, etc., can solve the problems of enlarged deformation surface, small fastening force, poor sealing performance, etc., and achieve stable clamping Connecting and bundling, realizing clamping and bundling, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing of description, the present invention will be further described.

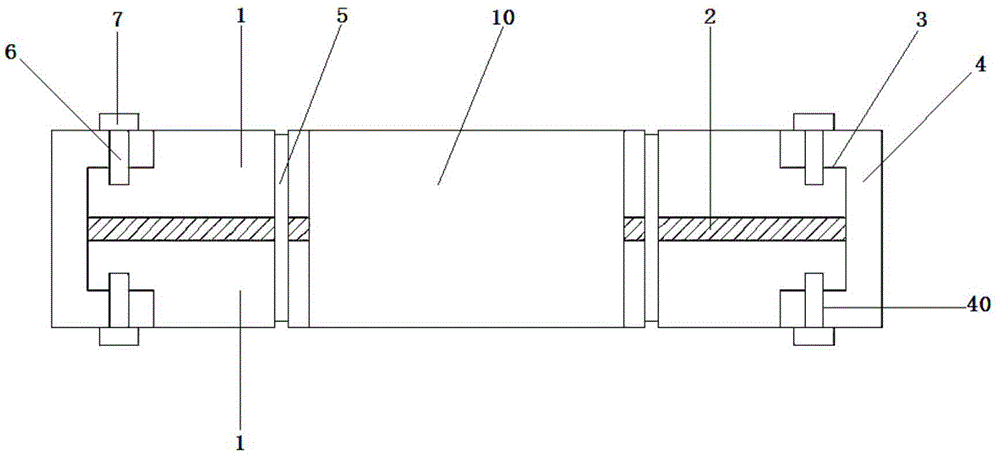

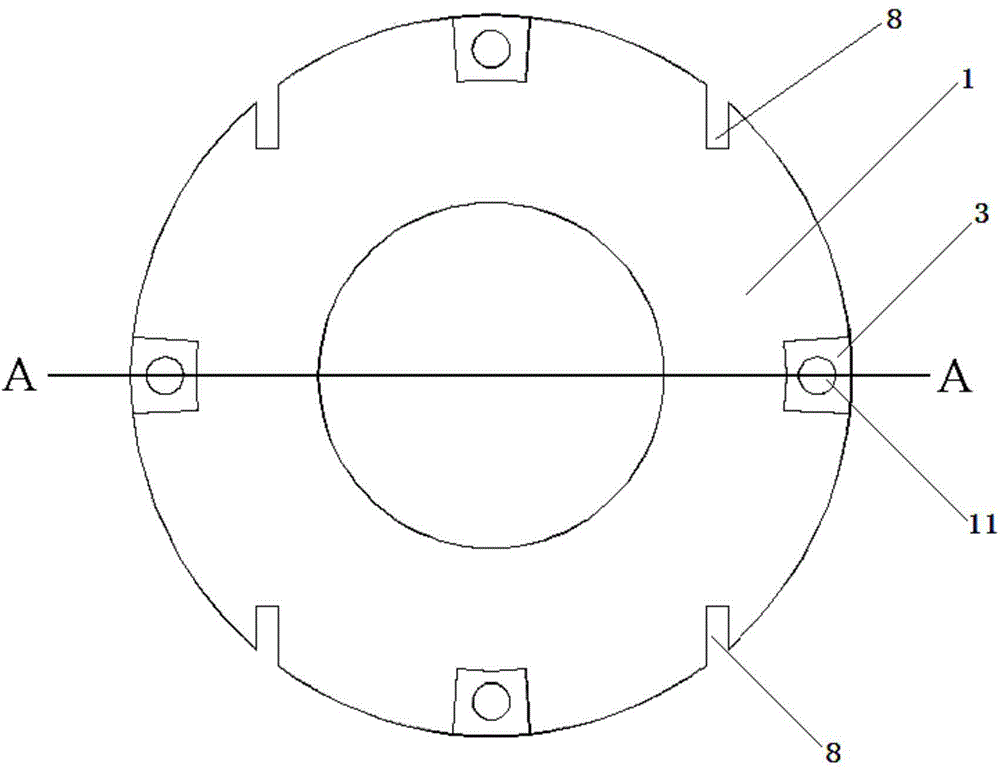

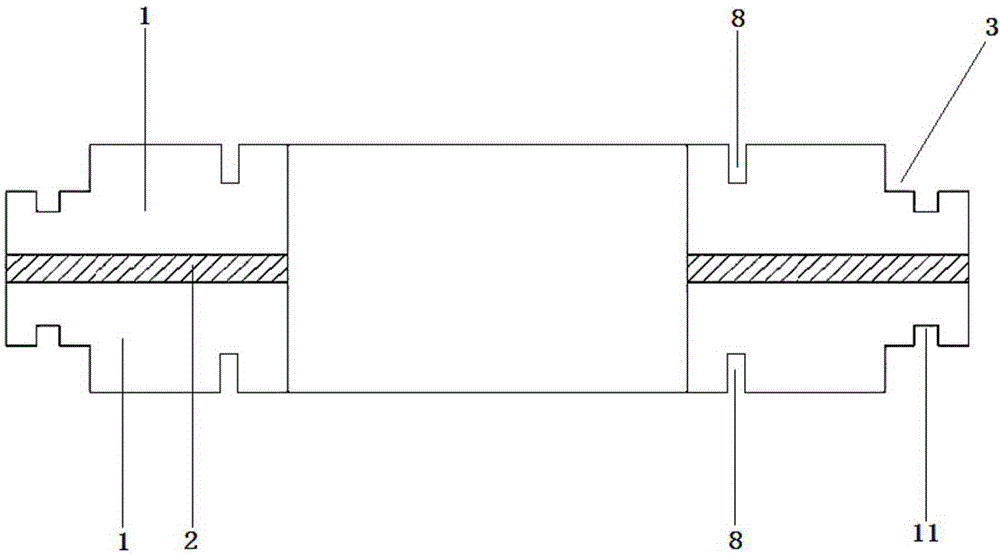

[0025] Such as figure 1 , figure 2 and image 3 A pipeline flange shown includes a pair of flanges 1 connected to the pipeline 10 and gaskets 2 between the flanges 1, and the flanges 1 are provided on the peripheral edge of the outer disk surface. There are pairs of evenly distributed notch slots 3; it also includes a side buckle pressure block 4 that clamps the paired flanges 1 from the notch slots 3, and an elastic spring that binds the paired flanges 1 from close to the pipe 10. hoop 5.

[0026] The side of the flange 1 in contact with the briquetting block 4 is provided with a first screw hole 11, and the briquetting block 4 is provided with a second screw hole 40 corresponding to the first screw hole 11, and the briquetting block 4 is passed through a screw. 6 passes through the first screw hole 11 and the second screw hole 40 and locks it with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com