Shifted-out assembling type module socket

An assembly type, socket technology, applied in the direction of coupling device, connecting device parts, electrical components, etc., can solve the problems of small distance between jacks, inability to extend the length of individual jack wires, and inability to take out individual jacks as needed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

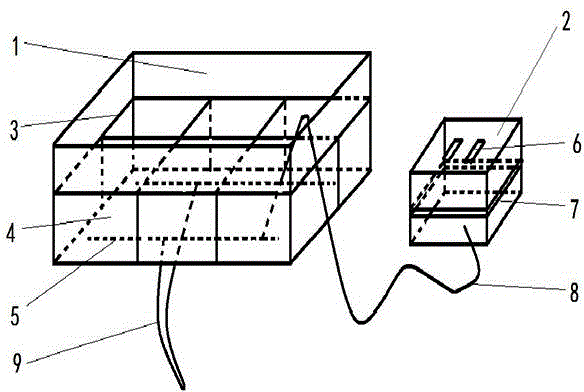

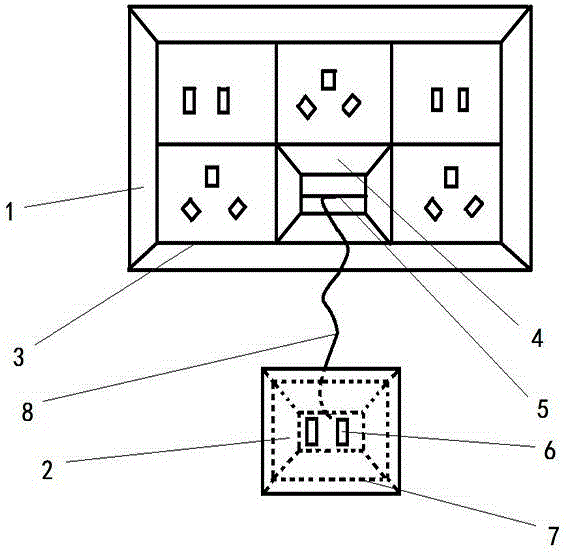

[0013] Such as figure 1 — figure 2 As shown, the design consists of a large board 1, a small box socket 2, a small box socket 3, a small box groove 4, a conductive metal 5, a jack 6, a fixed raised frame 7, a coil 8, and socket wires 9. Both the large board 1 and the small box socket 2 are rectangular parallelepiped, the fixed frame is located on the sides of the six small box grooves 4 of the large board 1, two rows of small box grooves 4 are respectively provided with the same conductive metal 5, and the plug The hole 6 is located on the upper surface of the small box socket 3, and the cuboid outside the small box socket 3 has a fixed raised frame 7 on all four sides, and the bottom part is connected with a coil 8 connected to the conductive metal 5 at the bottom of the large board 1; Metal 5-phase welding.

[0014] By arranging the small box socket 2 and the coil 8, the small box socket 2 can be removed, so that each small box socket 2 can be used for the plug, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com