A heater for an evenly heated air duct

A heater and air duct technology, applied in the field of electric heaters, can solve the problems of uneven heating effect and poor thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The detailed description will be given below in conjunction with the drawings in the embodiments of the present invention.

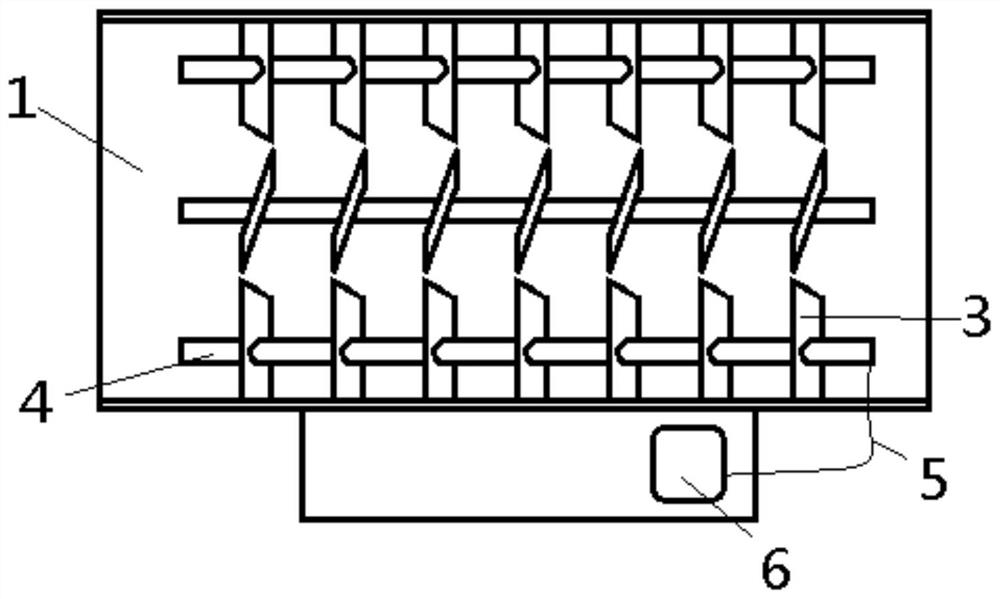

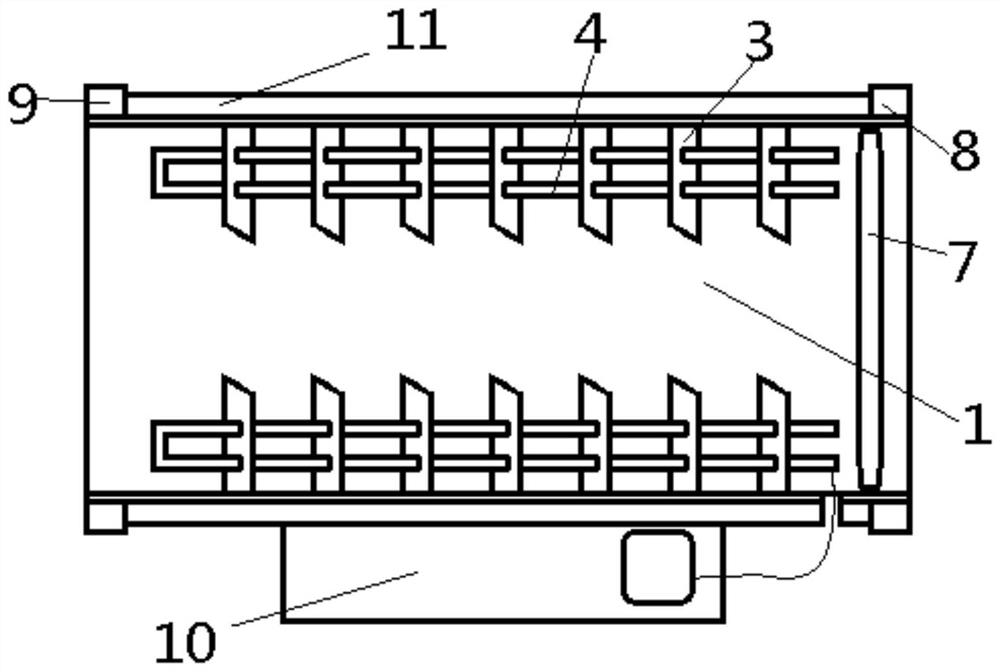

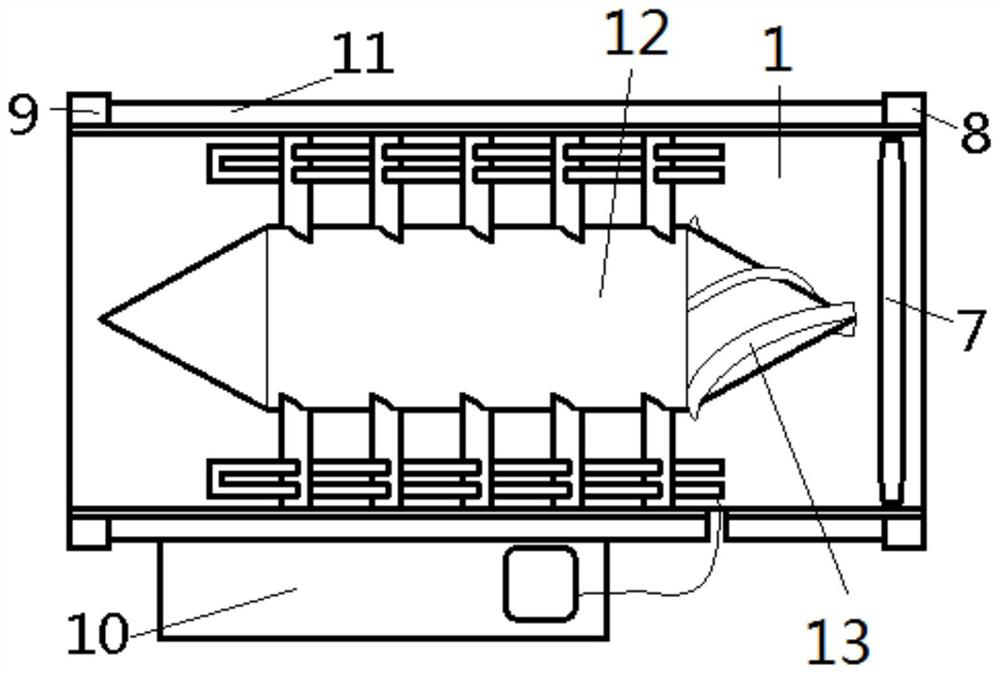

[0030] See figure 1 , A uniformly heated air duct heater, which mainly includes: a section of cylindrical air duct 1 arranged in a horizontal direction; the inner side wall of the air duct 1 is connected with several rows of heat dissipation fin groups arranged in the axial direction, each A row of radiating fins is composed of a number of fins 3 set parallel to each other, and each fin 3 has an inclination angle with the axis of the air duct 1 to form the blades of an axial fan in the air duct 1 The electric heating tube 4 runs through the center of each row of radiating fin groups, and each electric heating tube 4 is arranged parallel to the axis of the air duct 1; the inner side wall of the air duct 1 is penetrated with a wire hole corresponding to any end of each electric heating tube 4 , The wire hole is provided with wires 5 connected to the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com