A real-time compensation method for electrode loss based on spark discharge rate

An electrode loss and spark discharge technology, applied in electrode manufacturing, circuits, electric machining equipment, etc., can solve the problems of unstable servo feed, low processing efficiency, inaccurate compensation of electrode loss, etc., to overcome the instability of servo feed , Accurate loss compensation, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

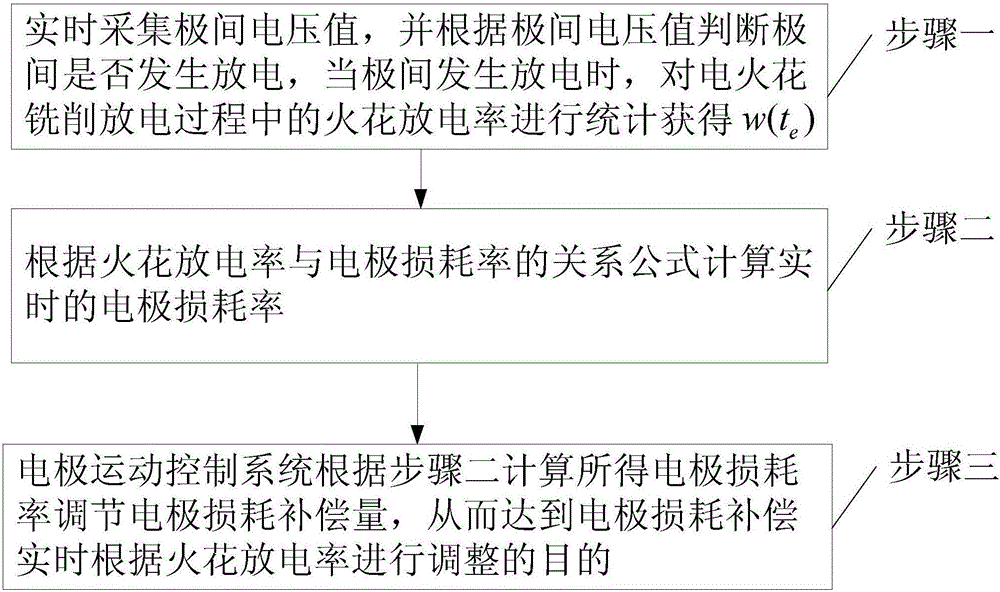

[0030] Specific implementation mode one: see figure 1 Describe this embodiment, a method for real-time compensation of electrode loss based on spark discharge rate described in this embodiment, the method includes the following steps:

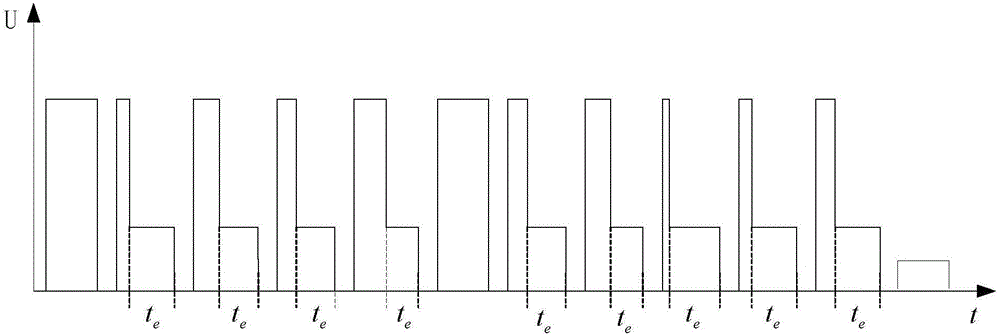

[0031] Step 1: Collect the inter-electrode voltage value in real time, and judge whether the inter-electrode discharge occurs according to the inter-electrode voltage value. When the inter-electrode discharge occurs, the spark discharge rate during the discharge process of EDM milling is statistically obtained:

[0032] w ( t e ) = ∫ 0 t t e d t t ,

[0033] t e is the discharge time within a single pulse; t is the sampling time; w(t e ) is the sp...

Embodiment

[0039] Example: When EDM is used to process high-temperature-resistant alloy turbine disks, since the surface of the turbine disk to be processed is relatively complex, there are many electrode idling strokes, which can show the superiority of the real-time compensation method for electrode loss based on the spark discharge rate. When the electrode moves on the surface of the turbine disk workpiece according to the pre-programmed processing program,

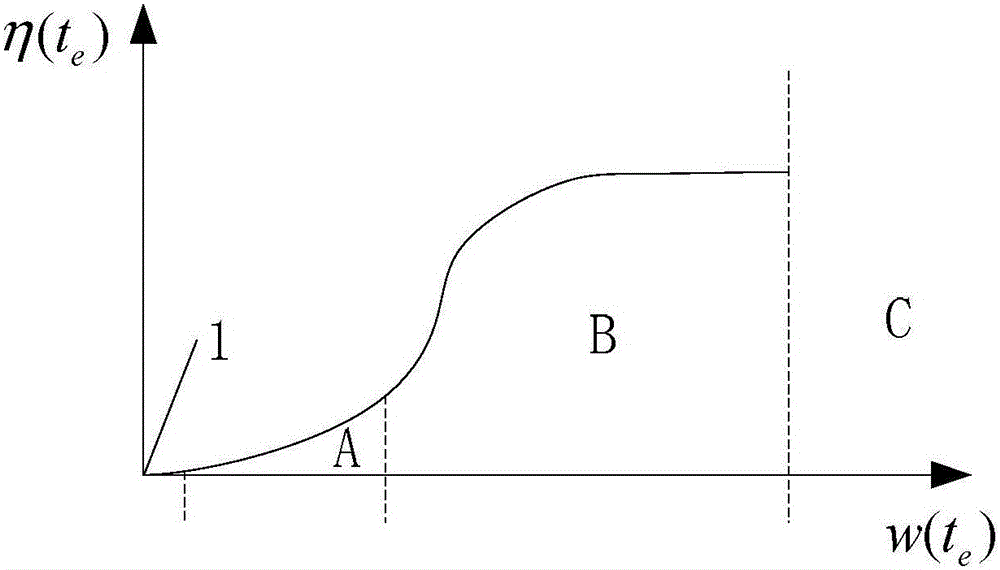

[0040] When the distance between the electrode and the workpiece has not been discharged, there is no electrode loss, and the detected spark discharge rate is zero, such as figure 2 Shown at no load, so no loss compensation will be performed during electrode movement;

[0041] When the electrode and the workpiece are just beginning to contact, the discharge is not continuous at this time, and the detected spark discharge rate is low, and the discharge rate is at figure 2 In the low spark discharge rate area shown, the correspo...

specific Embodiment approach 2

[0045] Specific implementation mode two: see figure 1 Describe this embodiment. The difference between this embodiment and the method for real-time compensation of electrode loss based on the spark discharge rate described in Embodiment 1 is that the conditions for judging whether discharge occurs between electrodes according to the voltage value between electrodes are as follows: The inter-electrode voltage value is between no-load and short-circuit reference voltage values.

[0046] In this embodiment, the electrode loss rate is adjusted in real time according to the spark discharge rate during electric discharge milling, and the electrode loss compensation amount changes with the change of the spark discharge rate.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap