Water catchment control method in underground coal gasification process and underground coal gasification method

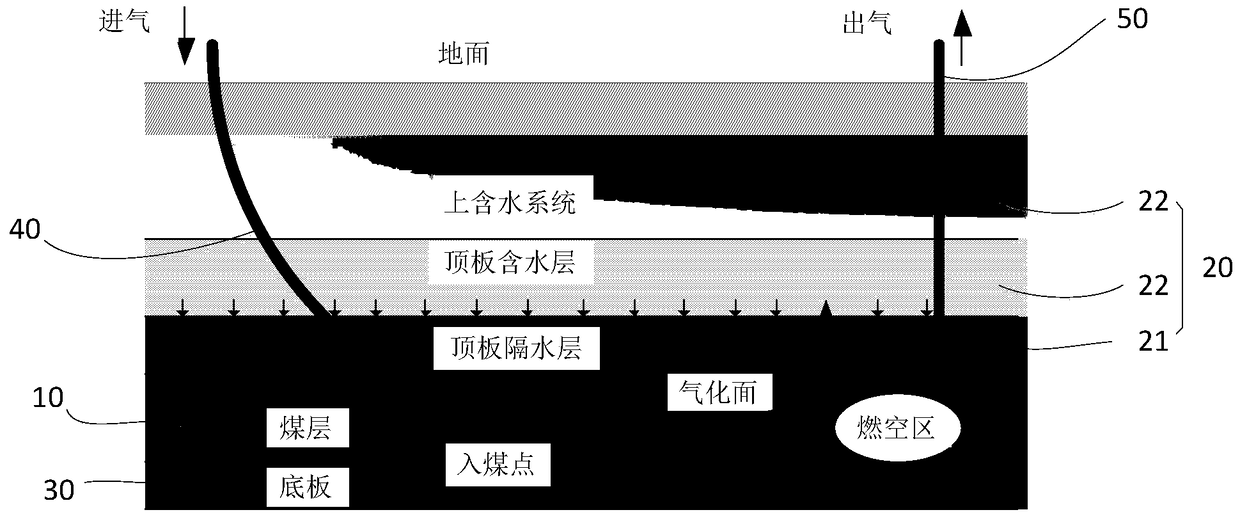

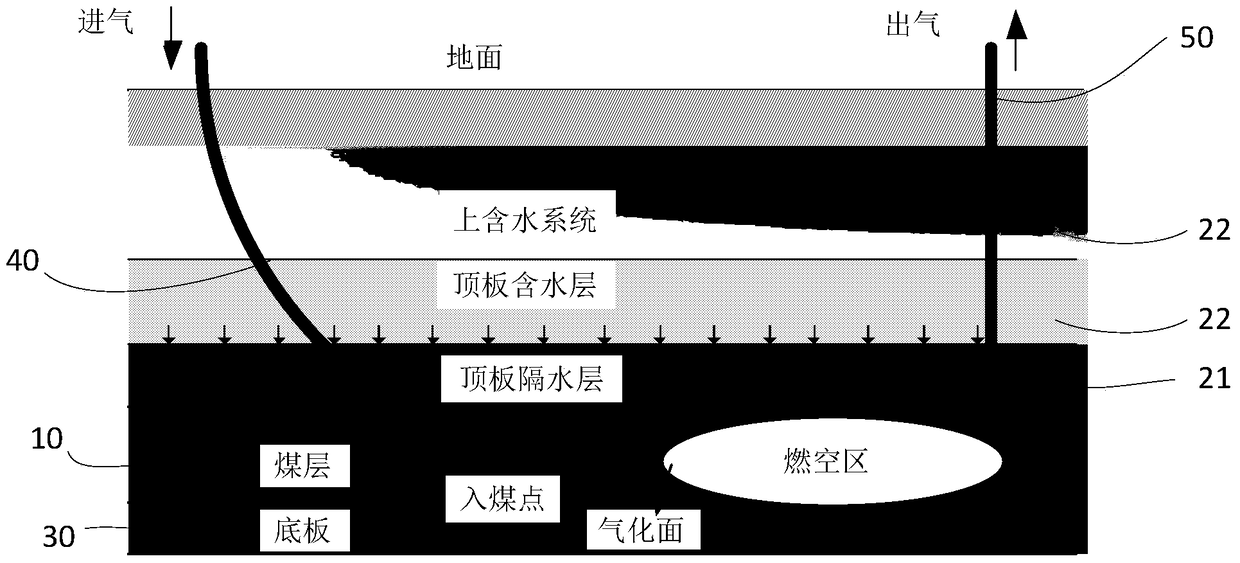

A technology of underground gasification and control method, which is applied in the control of water catchment in the process of underground coal gasification. In the field of underground coal gasification, it can solve the problem of poor controllability, single treatment method of coal seam water catchment, and inability to stably and effectively control coal seam catchment. Water volume and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

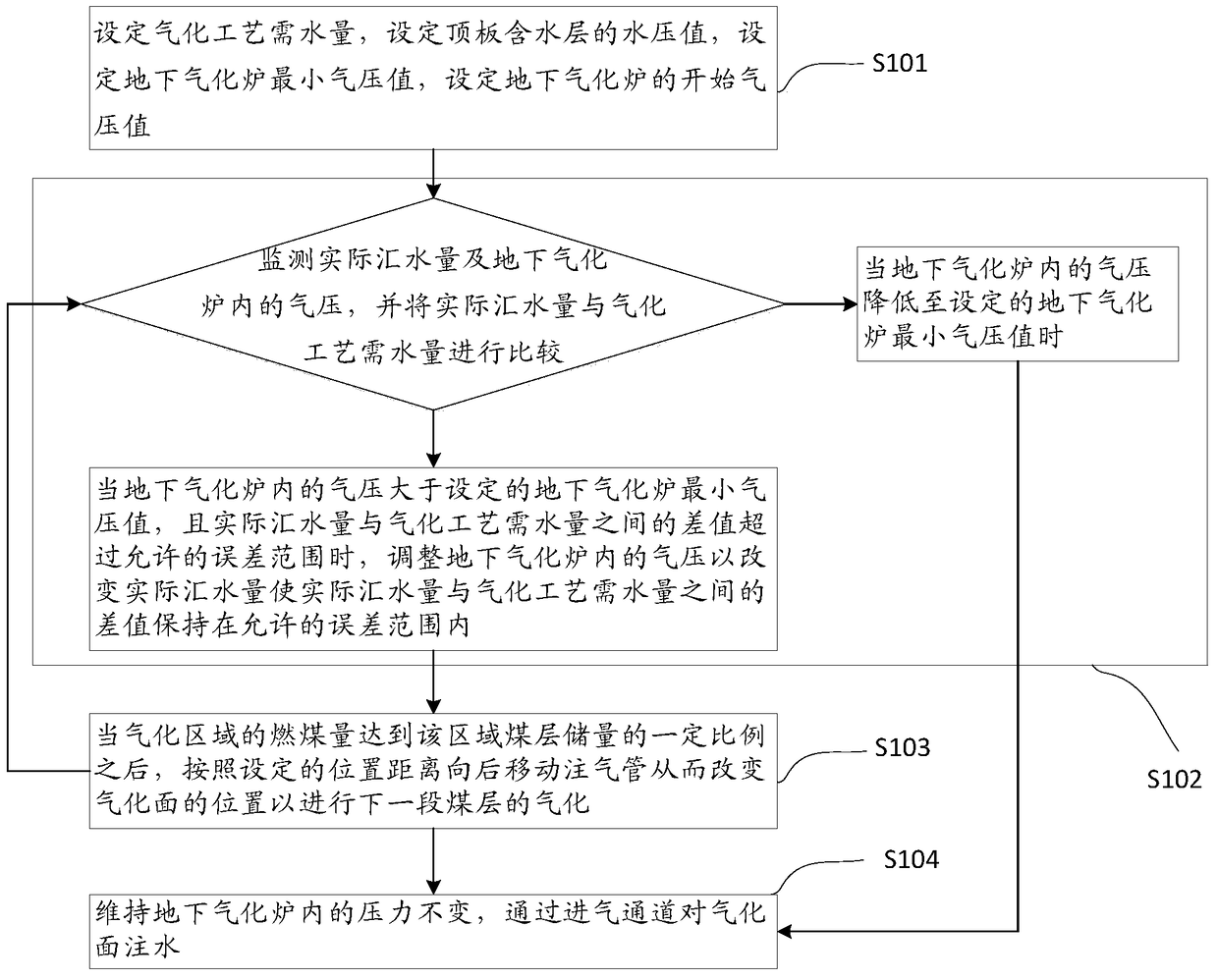

[0055] Please also refer to image 3 The method for controlling water catchment in the underground coal gasification process of the present invention is used to control the water catchment in the underground coal gasification process to ensure the stability of the gasification process. The steps of the method are as follows:

[0056] Step S101: Set the water demand of the gasification process, set the water pressure value of the roof aquifer, set the minimum pressure value of the underground gasifier, and set the starting pressure value of the underground gasifier.

[0057] The water demand of the gasification process and the minimum pressure value of the underground gasification furnace are calculated according to the process requirements of the underground coal gasification.

[0058] The water pressure of the roof aquifer is calculated according to the geological and hydrological conditions of the underground gasifier. The geographical location of the underground gasifier is...

Embodiment 2

[0070] Please also refer to Figure 4 , the steps of underground coal gasification method of the present invention are as follows:

[0071] Step S201: Set the water demand of the gasification process, set the water pressure value of the roof aquifer, set the minimum pressure value of the underground gasifier, and set the starting pressure value of the underground gasifier; Gasification agent, and ignition to start gasification.

[0072] The water demand of the gasification process and the minimum pressure value of the underground gasification furnace are calculated according to the process requirements of the underground coal gasification.

[0073] The water pressure of the roof aquifer is calculated according to the geological and hydrological conditions of the underground gasifier. The geographical location of the underground gasifier is different, and the water pressure of the roof aquifer is also different.

[0074] The setting of the starting pressure value of the under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com