Shielding-free laser-path-coaxial powder conveying method and shielding-free laser-path-coaxial powder conveying device

A coaxial powder feeding and unshielded technology, which is applied in the direction of improving process efficiency and energy efficiency, can solve the problems of burning wire feeding tube and wire feeding device failure, and achieve the effect of avoiding burning and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

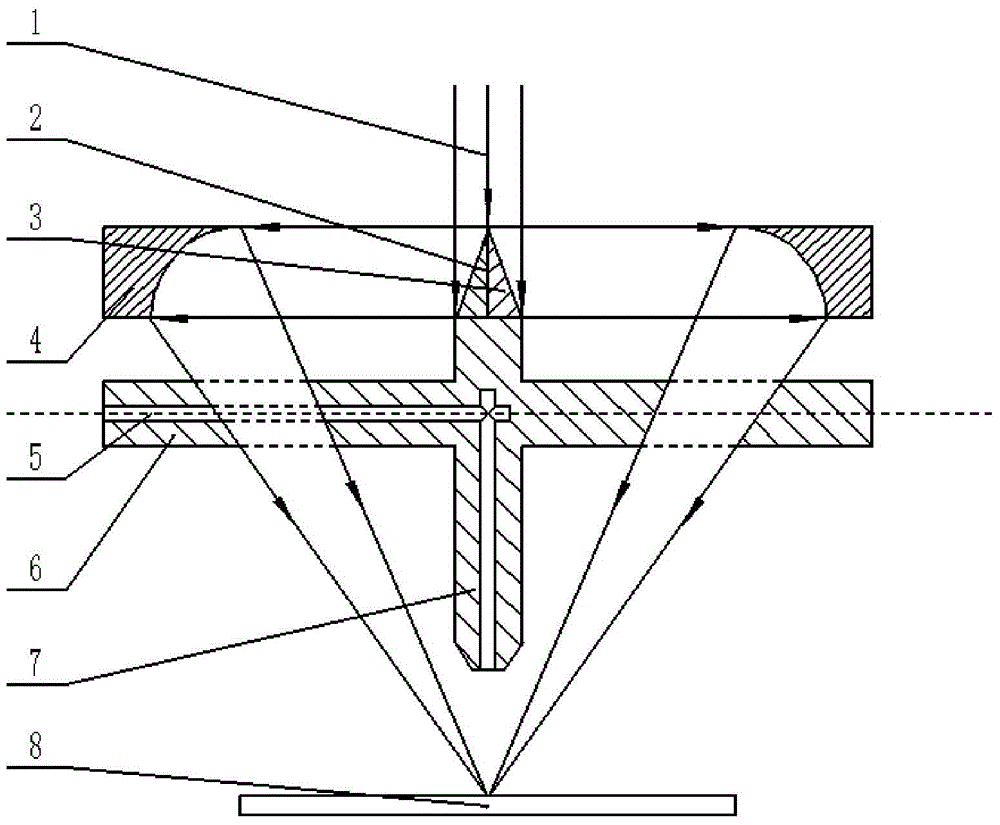

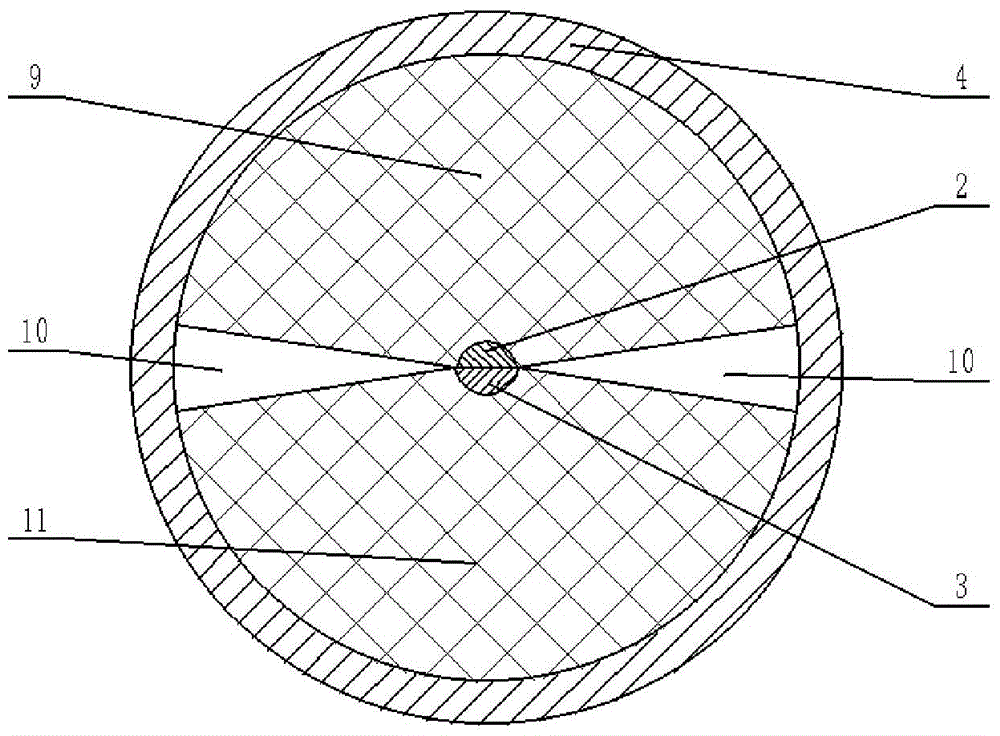

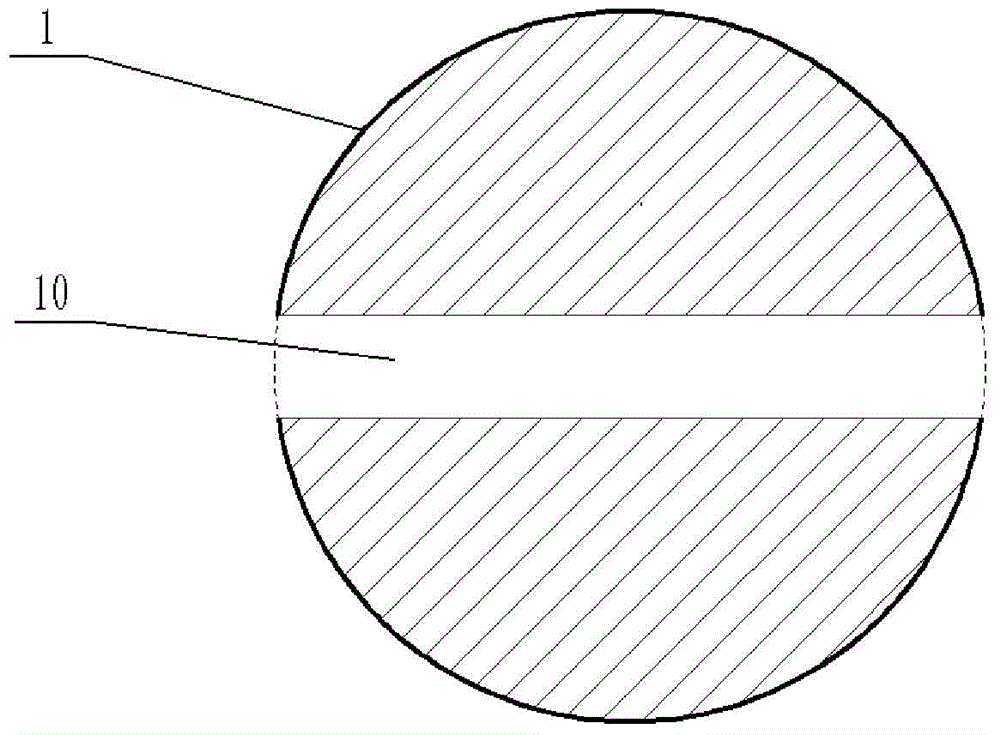

[0038] A coaxial powder feeding method without shielding the laser light path, which mainly divides the incident laser beam into several reflective areas and non-laser areas through a certain method, such as figure 1 , 2 As shown, the laser is divided in this way by the arc conoscopic mirror composed of two inferior arcs. The light beam in the reflective area is focused by the ring focus lens to form a ring cone beam and finally converges on the substrate, while in the non-laser area because there is no laser beam, there will be no laser beam from the plane where the ring focus lens is located to the plane where the substrate is located. Several segments of approximately cone-shaped laser-free areas appear. image 3 for figure 1 The optical path cross-section of the plane at the dotted line, given by image 3 As shown, there is a laser-free region in the plane where no laser passes through at both ends. Thus, if Figure 4 As shown, the feeding pipeline located outside the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com