Rotation and disconnection preventing mounting structure of car sensor

A technology of automotive sensors and installation structures, which is applied in vehicle safety arrangements, vehicle parts, transportation and packaging, etc., can solve the problems of no anti-rotation structure or anti-rotation failure, poor stability, and functional failure, and achieve the effect of anti-rotation and anti-loosening Good, good stability, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

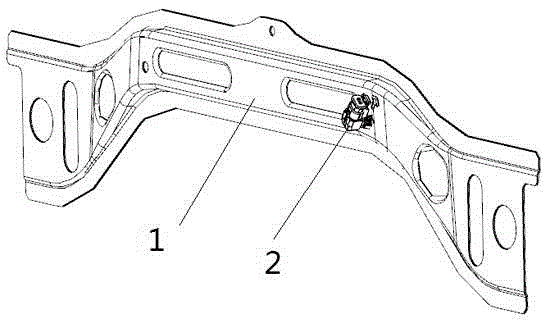

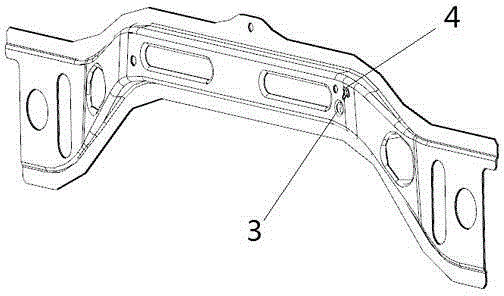

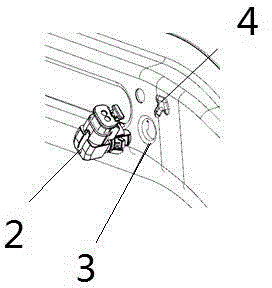

[0023] Figure 1 to Figure 5 The reference numerals in the figure are: front bumper anti-collision beam 1; automobile sensor 2; clip 21; flange hole 3; flange flange 31; anti-rotation groove 32; installation mark 4.

[0024] like Figure 1 to Figure 5 As shown, an anti-rotation and anti-off installation structure of an automobile sensor includes a front protection anti-collision beam 1 and an automobile sensor 2, the front protection anti-collision beam 1 is provided with a flange hole 3, and the automobile sensor 2 is provided with Clip 21, the flange hole 3 includes a flange 31, the flange 31 is provided with an anti-rotation groove 32, the automobile sensor 2 has at least two clips 21, the automobile sensor The clamping foot 21 of 2 passes through the flange hole 3, and the clamping foot 21 is snap-connected with the flange hole 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com