Bolt with double hexagonal bolt heads

A technology of hexagonal bolts and head bolts, applied in the direction of bolts, screws, nuts, etc., can solve problems such as bolt looseness, and achieve the effect of ensuring structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

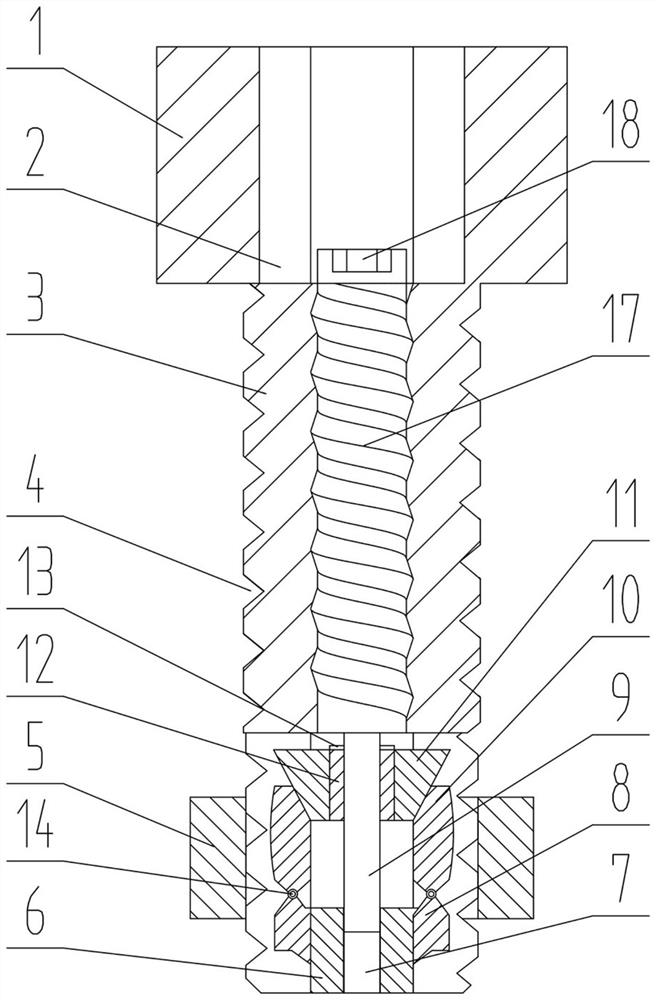

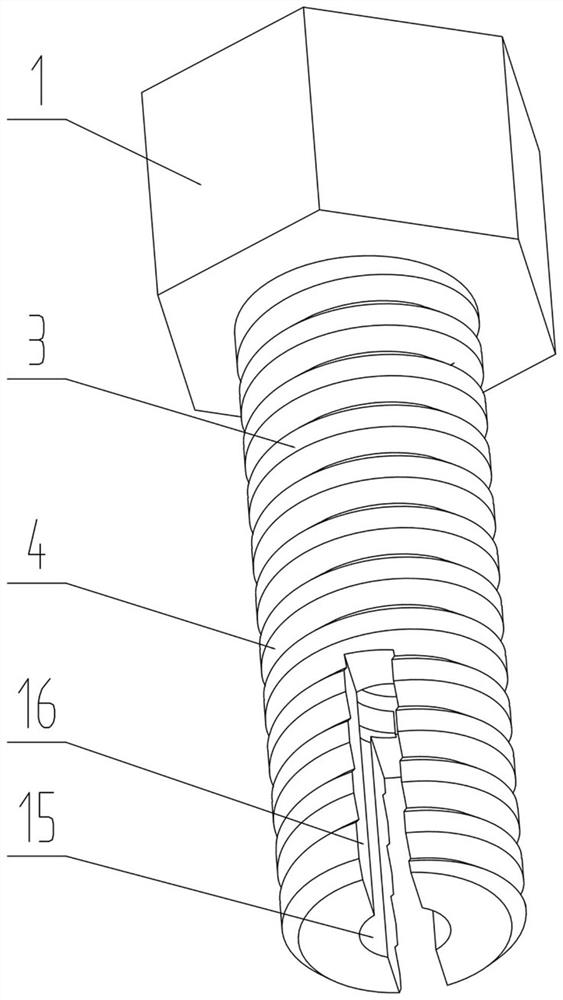

[0017] A double hexagon bolt head bolt, comprising a bolt head 1 and a screw 3 integrally formed, the outside of the screw 3 is processed with an external thread 4, the top of the bolt head 1 is processed with a head cavity 2 downwards, the head The cavity 2 extends downward from the top of the bolt head 1 to the meeting surface of the bolt head 1 and the screw 3; The side openings 16 on both sides of the bottom end are communicated; the inner surface of the screw cavity 15 located above the side opening 16 is processed with internal threads, and the screw cavity 15 is connected to the limiting rod body 17 through internal threads, and the top end of the limiting rod body 17 extends Out of the screw cavity 15 and connected to the limit adjustment end 18, the bottom end of the limit rod body 17 is connected with the adjustment rod body 9, and the bottom of the adjustment rod body 9 is provided with a thread that is connected with the cylinder adjustment cavity 7 in the limit pos...

Embodiment 2

[0019] On the basis of Embodiment 1, the spacer post 6 described in the present invention is a column structure, and the spacer film 8 of sheet structure is fixed on both sides of the spacer post 6, and the two sides of the spacer film 8 are connected with The side opening 16 at the corresponding position is in contact; the top of the limiting bottom sheet 8 is hinged to the limiting top sheet 10 through the hinge shaft 14, and the both sides of the limiting top sheet 10 are in contact with the side opening 16 at the corresponding position; The top inner side of the top sheet 10 is processed with an inclined surface in contact with the outside of the outer support sheet 11; the outer support sheet 11 is a sheet structure and the inner side is fixed on the outer support ring body 12, and the outer support ring body 12 is sleeved on the adjustment rod body 9, a rod limit ring 13 is fixed on the adjustment rod body 9 above the outer supporting ring body 12; the top surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com