Spray drift adjuvant formulation and method of use

A preparation and adjuvant technology, which is applied in the field of spray drift and suppression of spray drift, can solve problems such as difficult incorporation into spray liquid, and achieve the effects of reducing economical savings, saving time, and reducing the possibility of phytotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The invention will be further described with reference to the following non-limiting example of a spray liquid adjuvant according to the invention and the following figures:

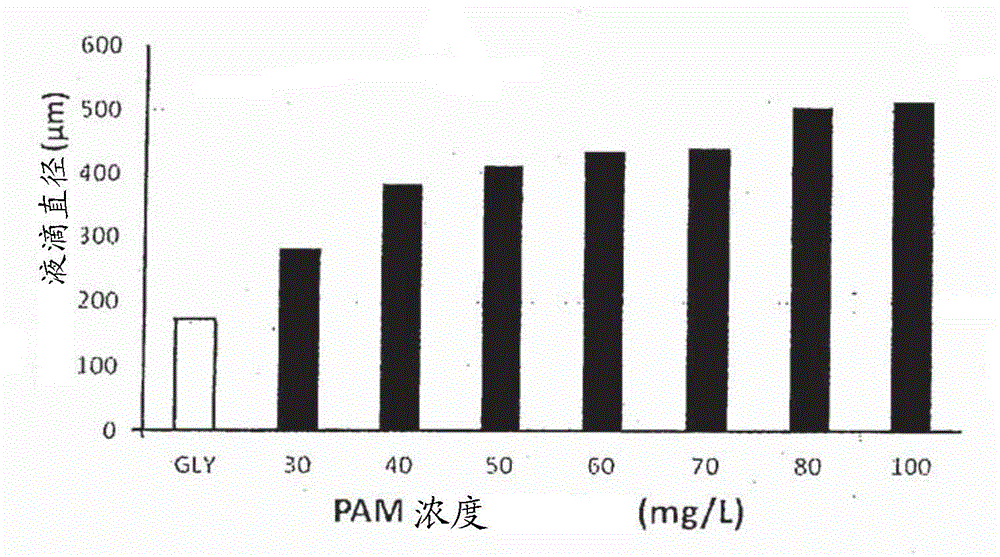

[0085] · Figure 1 graphically relates PAM concentration (mg / L) versus droplet diameter (microns) Dv50 (Fig. 1(a)) and PAM concentration (mg / L) versus % volume <100 microns (Fig. 1(b)) Plotted plot of XR11002 nozzle droplet size measurements; where all adjuvant test solutions contained 0.032% superwetting agent

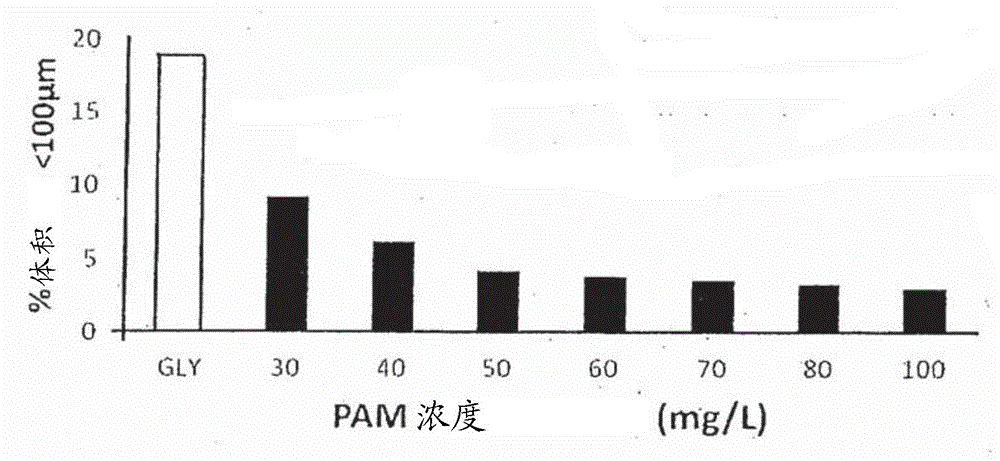

[0086] · Figure 2 graphically relates to PAM concentration (mg / L) versus droplet diameter (microns) Dv50 (Fig. 2(a)) and PAM concentration (mg / L) versus droplet diameter <100 microns (Fig. 2(b)) A plot of TT11002 nozzle droplet size measurements; where all adjuvant test solutions contained 0.032% superwetting agent, and

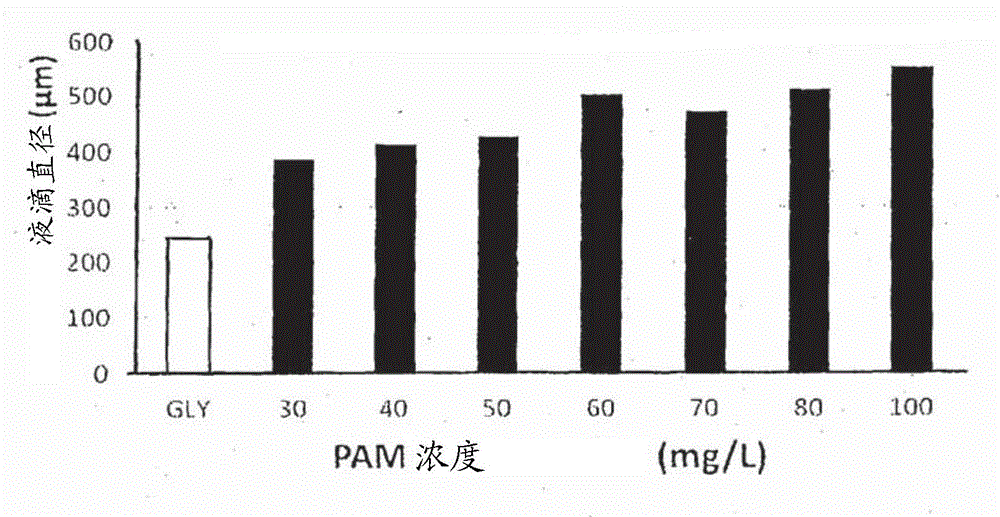

[0087] · Figure 3 graphically relates to PAM concentration (mg / L) versus droplet diameter (microns) Dv50 (Fig. 3(a)) and PAM concentration (mg / L) versus droplet diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com