Pipe bender and its control method

A control method and pipe bending machine technology, applied in the direction of manufacturing tools, feeding devices, positioning devices, etc., can solve the problem of high cost, achieve low cost, improve pipe bending efficiency, and facilitate the realization of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

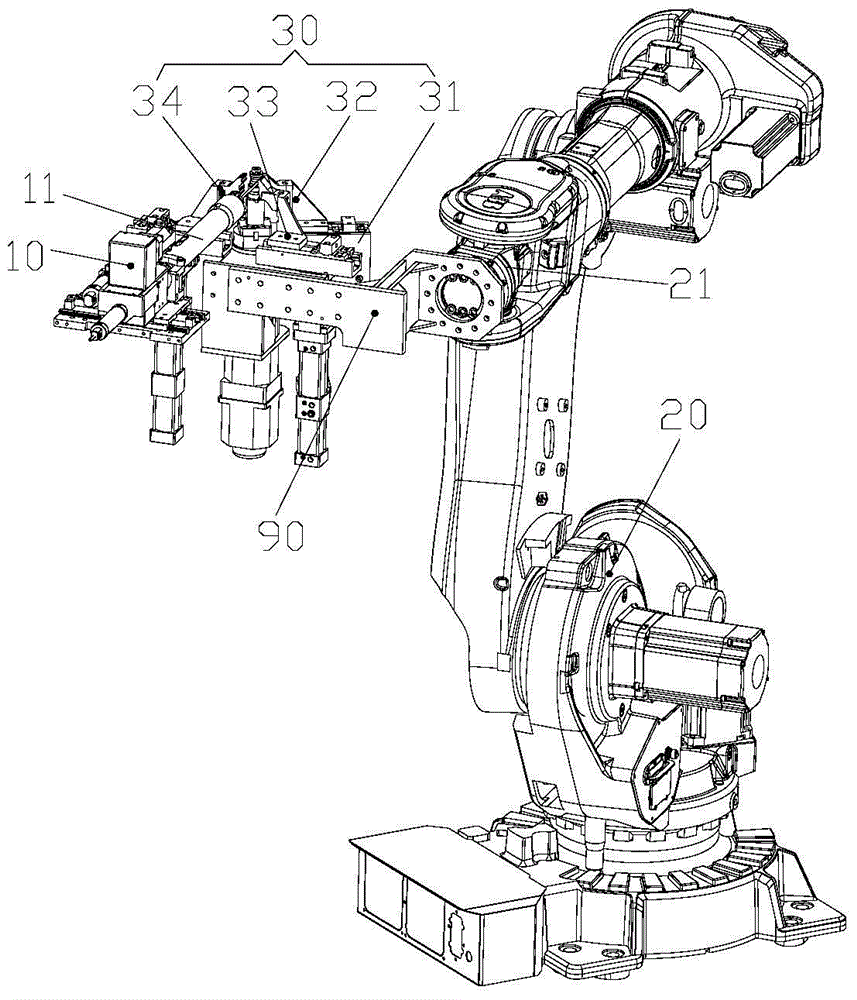

[0032] see Figure 1 to Figure 7 As shown, according to one aspect of the present invention, a pipe bending machine is provided.

[0033] In this embodiment, the pipe bending machine includes a feeding device 10 , a robot 20 and a pipe bending device 30 .

[0034] Wherein, the feeding device 10 is provided with a positioning structure 11 for locating the pipe to be bent, so as to facilitate the positioning of the pipe during the pipe bending operation; The height and horizontal direction can be set movably, so that the structure set on the support arm 21 can move freely in the space;

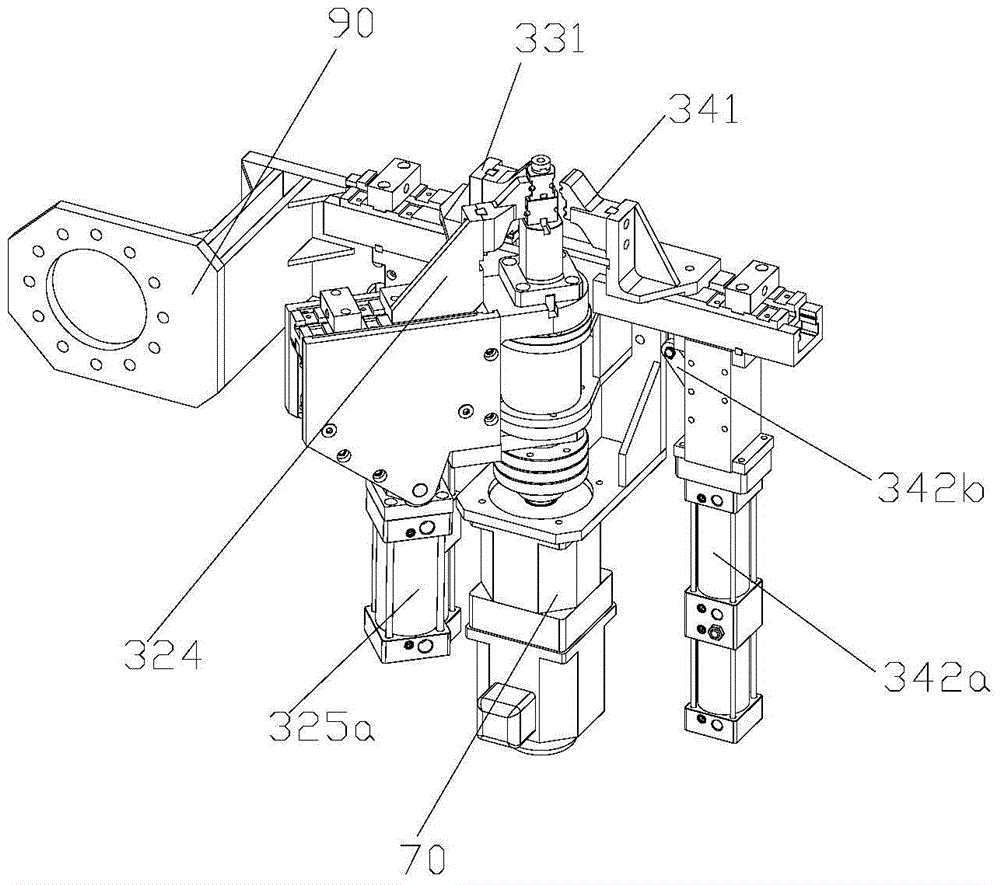

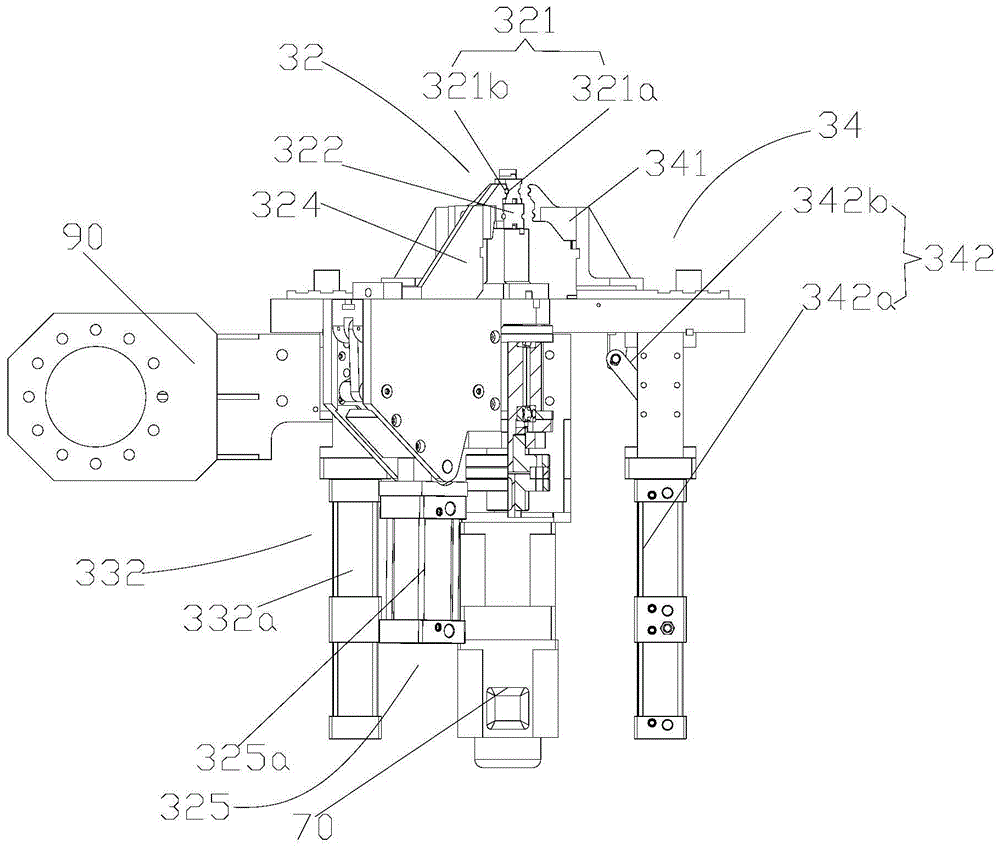

[0035] see figure 1 with figure 2 As shown, the pipe bending device 30 of this embodiment includes a mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com