Cylinder screw mounting structure and compressor

A technology for mounting structures and screws, which is applied to parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve problems such as uneven screw load distribution, and achieve uneven screw load distribution. The effect of simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

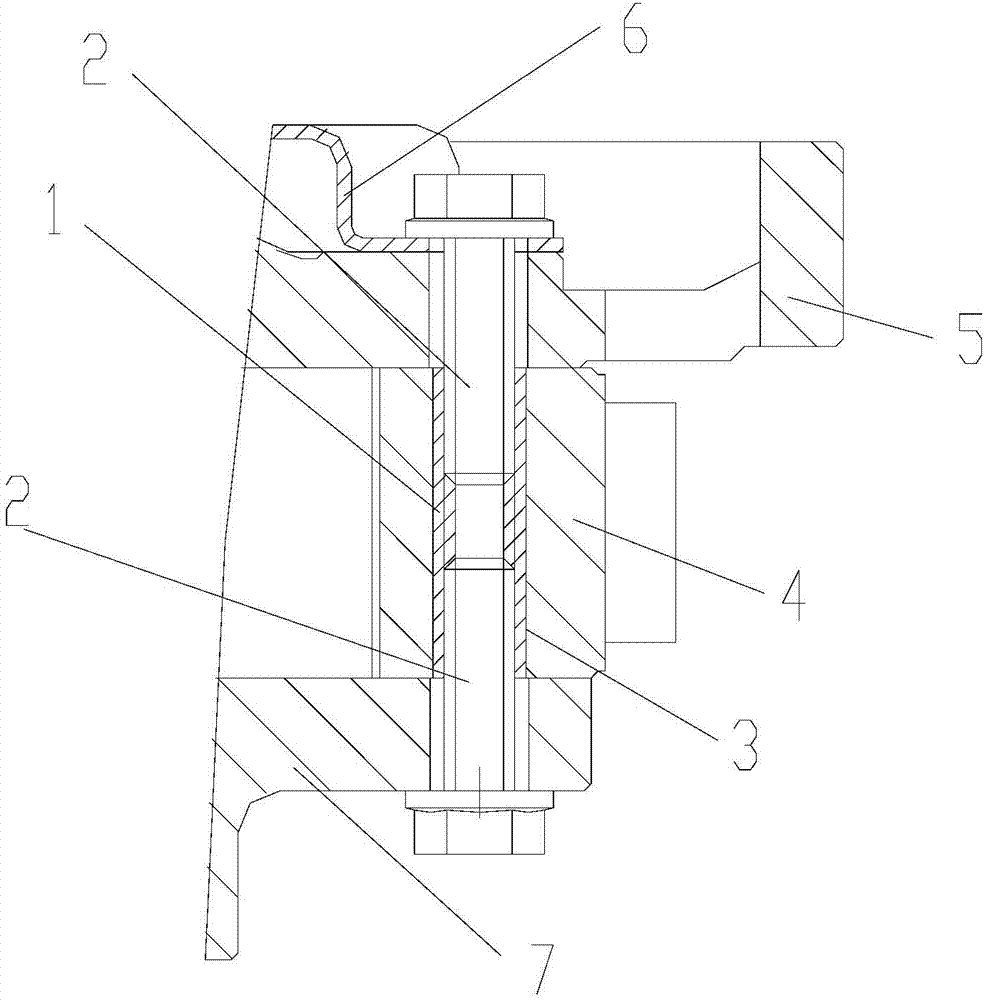

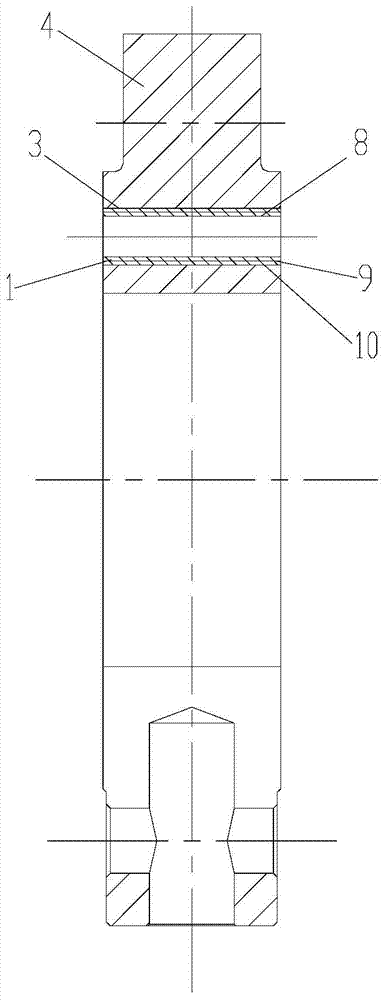

[0034] As a possible embodiment, the mounting hole 3 is provided with an internal thread 10 in the mounting hole;

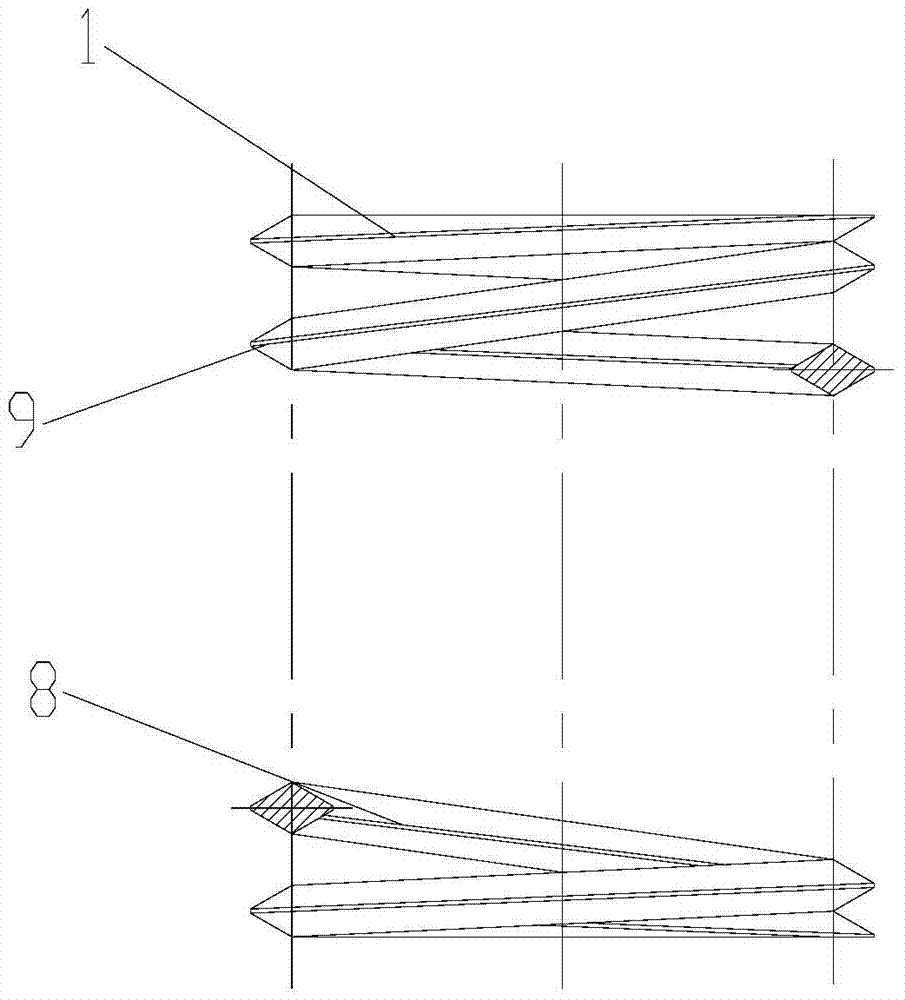

[0035] The screw sleeve 1 includes a screw sleeve external thread 9;

[0036] The external thread 9 of the screw sleeve is compatible with the internal thread 10 of the mounting hole;

[0037] The screw sleeve 1 is fixedly installed in the installation hole 3 through the screw sleeve external thread 9 in a threaded manner.

[0038] Installing the threaded sleeve 1 into the installation hole 3 through threaded connection is not only easy to operate, but also ensures that the screw sleeve 1 is reliably fixed in the installation hole 3 .

[0039] As a possible implementation manner, the internal thread 8 of the screw sleeve and the external thread 9 of the screw sleeve are concentric bodies.

[0040] Since the stress on the screw 2 acts on the inner threaded hole 8 of the screw sleeve, and the reverse stress generated by the inner thread 10 of the installation hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com