A motor stator stamping

A technology for stator punching and motor stator, which is used in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of bending deformation of the motor shaft, reduction of the radial size of the motor, damage to the accelerated bearing, etc., and achieves uniform electromagnetic air gap. , Reduce the processing cost, the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

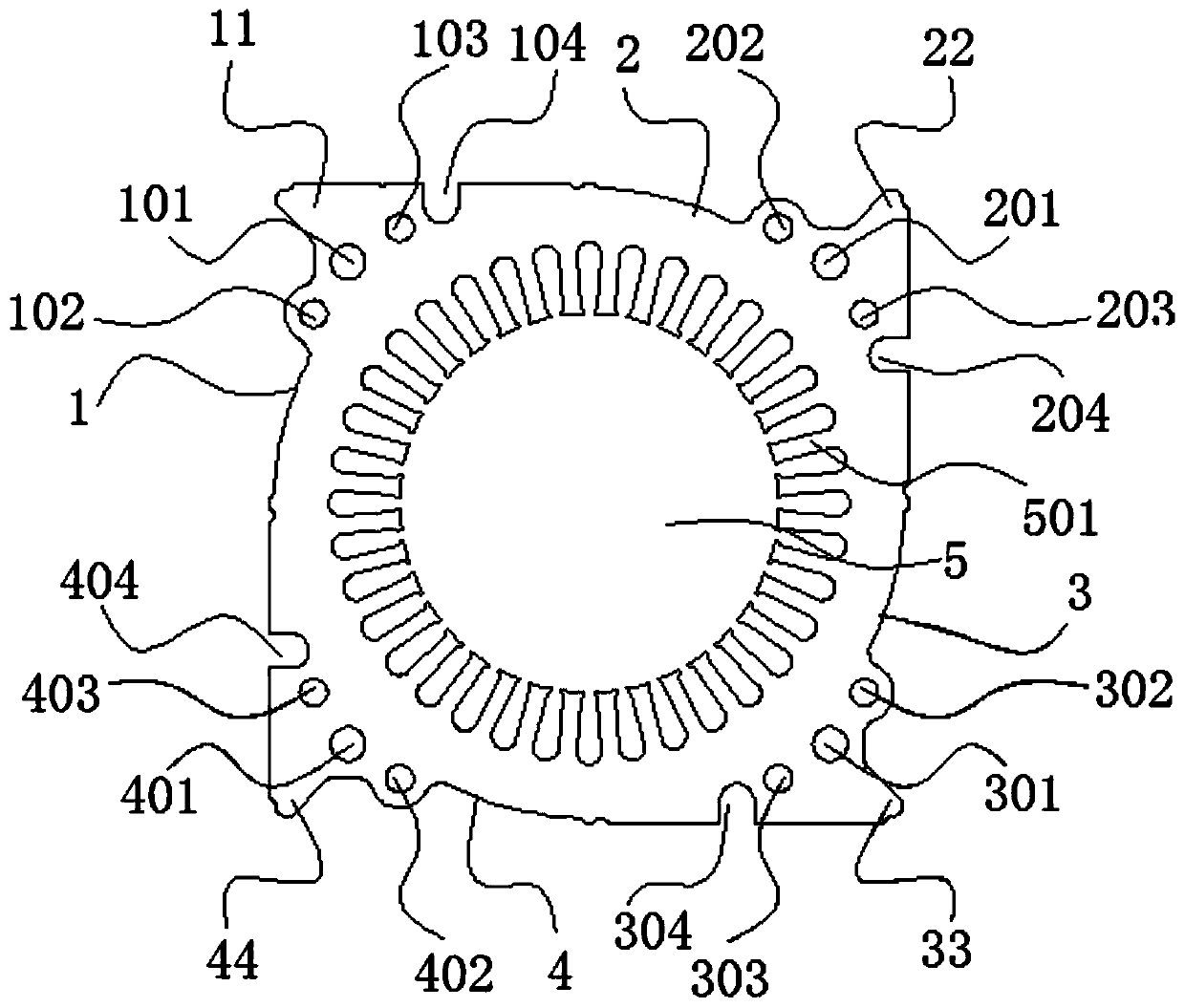

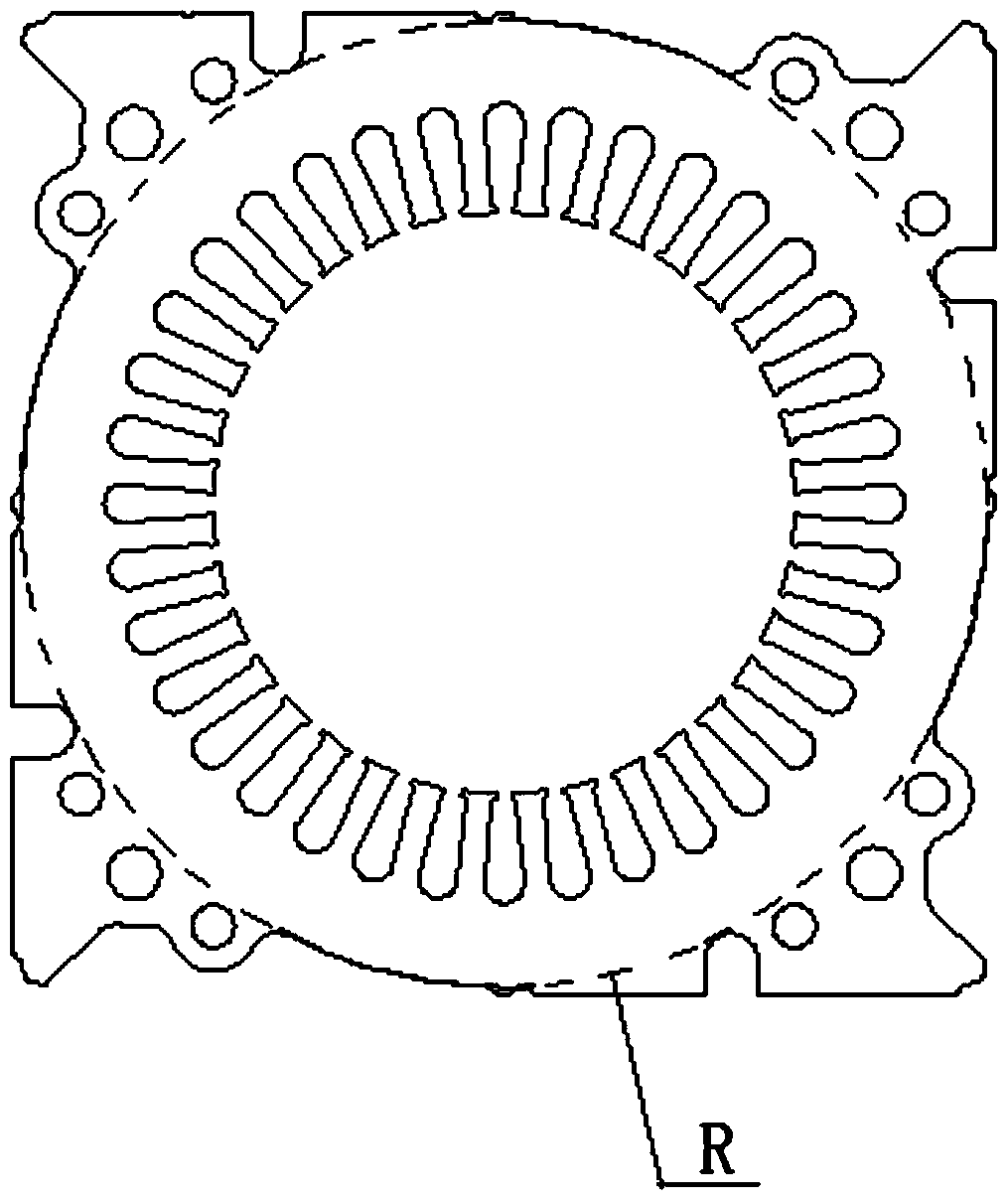

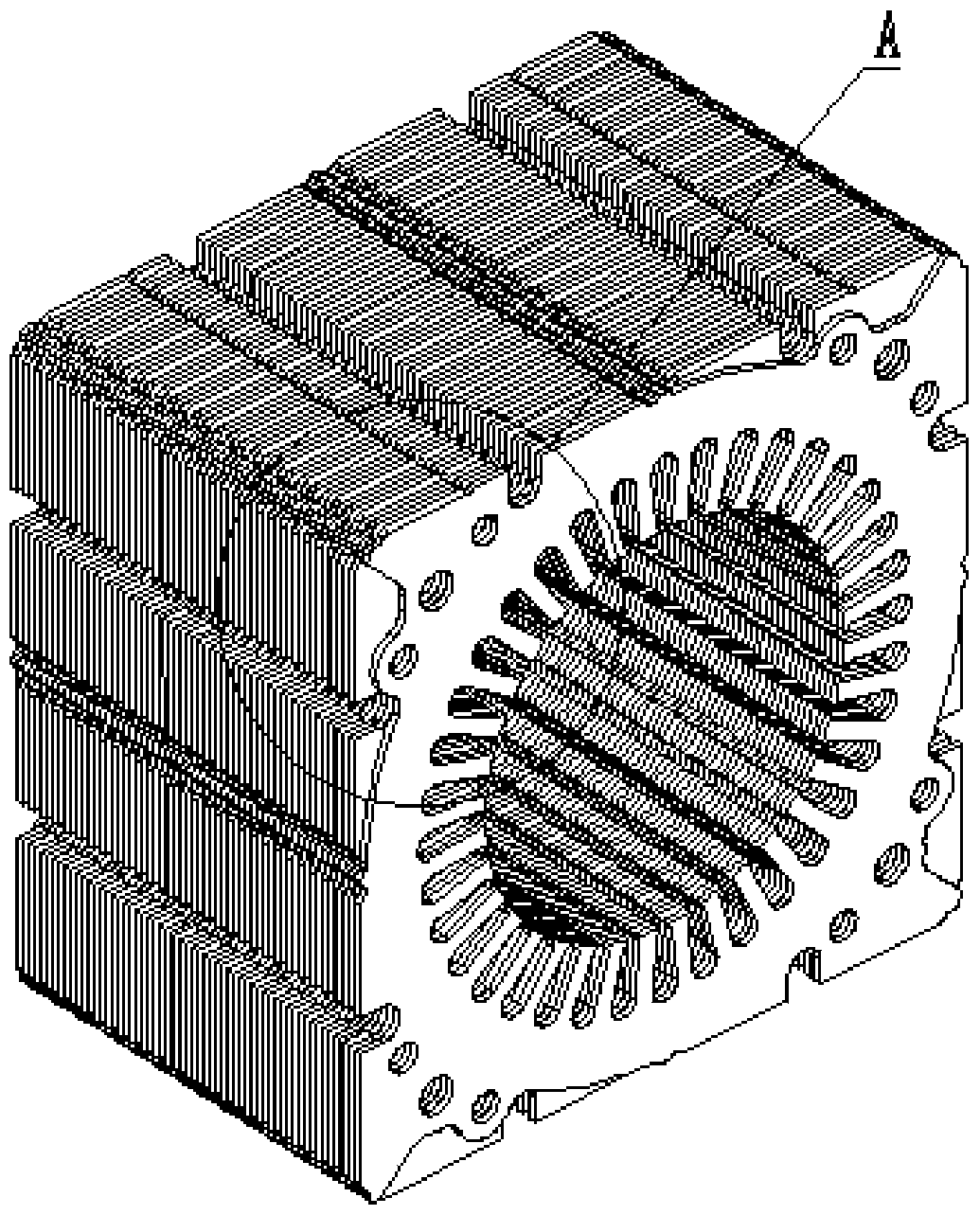

[0036] see figure 1 and 2 , the present embodiment discloses a stator punching sheet of a motor, and the center of the stator punching sheet has a central through hole 5 . The outer contour of the stator punch includes four concentric arc segments. The four concentric arcs are respectively arc segment I1, arc segment II2, arc segment III3 and arc segment IV4.

[0037] Such as figure 2 As shown by the dotted line, arc segment I1, arc segment II2, arc segment III3 and arc segment IV4 are on the same circle (hereinafter referred to as circle o), and any two adjacent arc segments The distance between them is equal.

[0038] Between the arc segment I1 and the arc segment II2 is a sharp corner portion I11. Between the arc segment II2 and the arc segment III3 is a sharp corner part II22. Between the arc segment III3 and the arc segment IV4 is a sharp corner portion III33. Between the arc segment IV4 and the arc segment I1 is a sharp corner part IV44. same as figure 2 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com