A motor end cover and method fixed by positioning pins

A technology of motor end cover and positioning pin, which is applied in the field of motor end cover installation and motor stator stamping. It can solve the problems of motor shaft bending deformation, motor radial size reduction, and acceleration bearing damage, etc., to achieve uniform and reduced electromagnetic air gap. Low processing cost and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

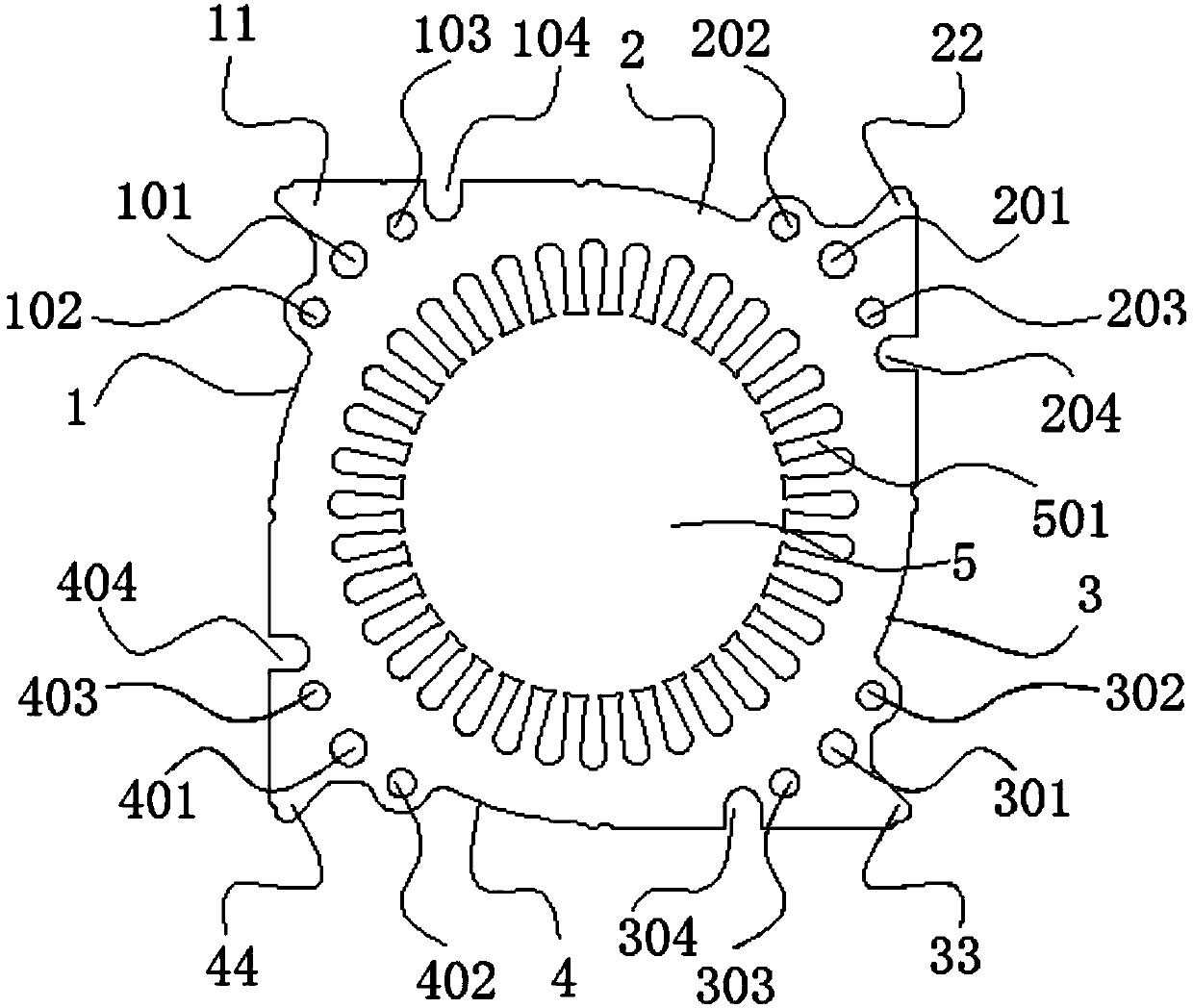

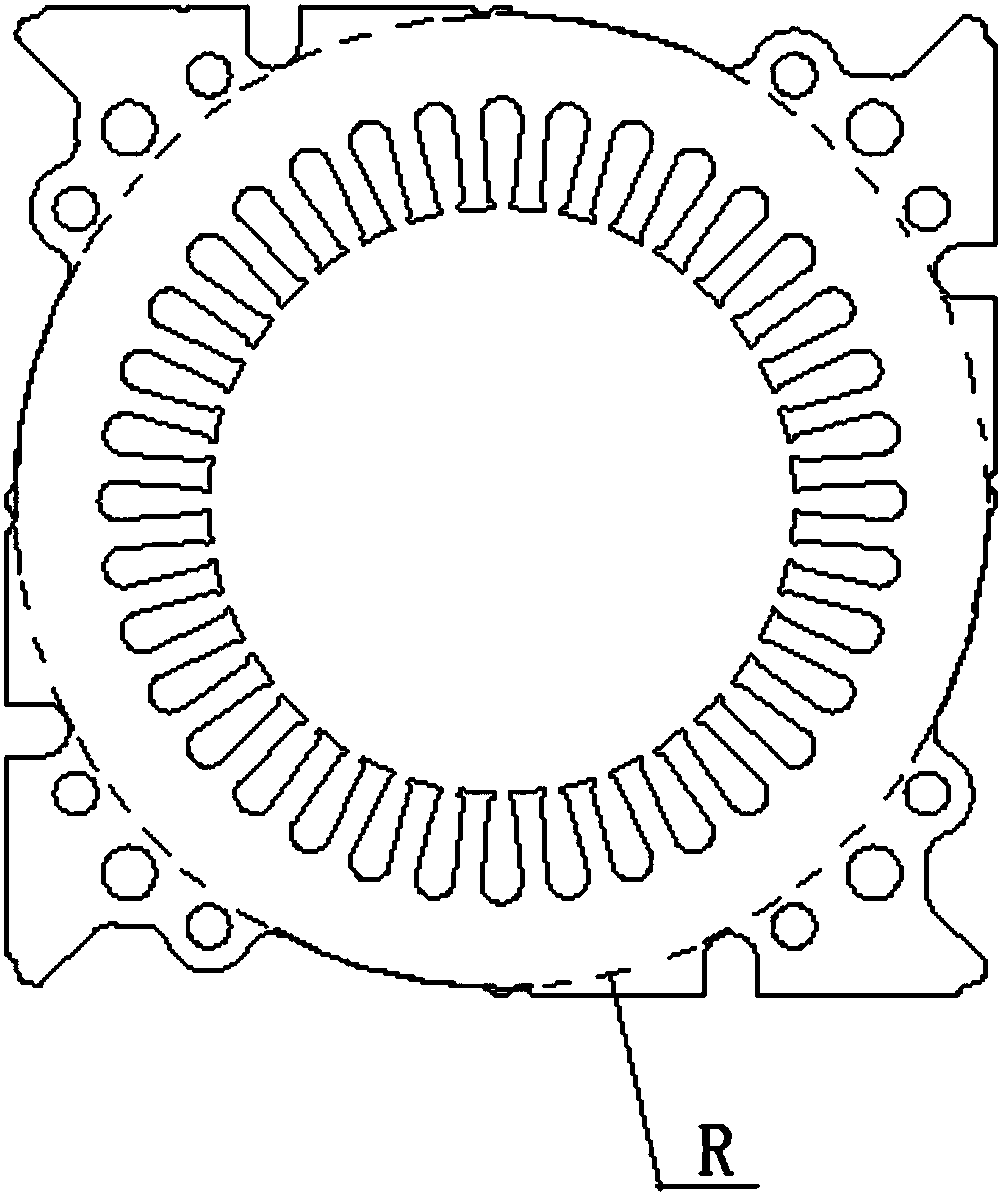

[0044] see figure 1 and 2 , the present embodiment discloses a stator punching sheet of a motor, and the center of the stator punching sheet has a central through hole 5 . The outer contour of the stator punch includes four concentric arc segments. The four concentric arcs are respectively arc segment I1, arc segment II2, arc segment III3 and arc segment IV4.

[0045] Such as figure 2 As shown by the dotted line, arc segment I1, arc segment II2, arc segment III3 and arc segment IV4 are on the same circle (hereinafter referred to as circle o), and any two adjacent arc segments The distance between them is equal.

[0046] Between the arc segment I1 and the arc segment II2 is a sharp corner portion I11. Between the arc segment II2 and the arc segment III3 is a sharp corner part II22. Between the arc segment III3 and the arc segment IV4 is a sharp corner portion III33. Between the arc segment IV4 and the arc segment I1 is a sharp corner part IV44. same as figure 2 As sh...

Embodiment 2

[0060] This embodiment discloses an installation method of a motor end cover fixed by positioning pins:

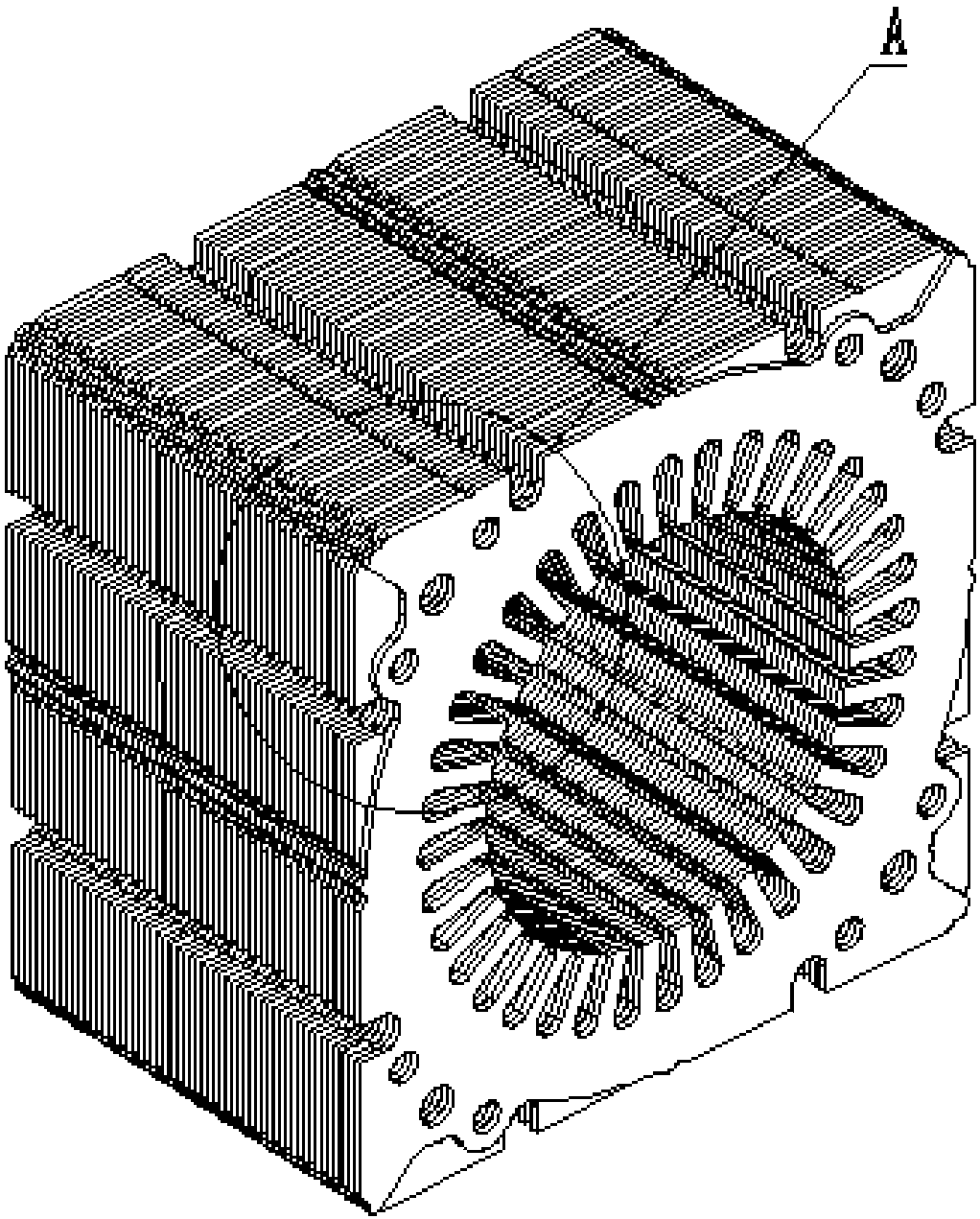

[0061] 1) Prepare two motor end covers 6, four to eight positioning pins 7, and several pieces of punched motor stator sheets as described in Embodiment 1.

[0062] 2) The stator punches are stacked together to form a stator core, wherein any two adjacent stator punches are mirror images of each other. The screw holes on the stator punch overlap to form the screw holes of the stator core. The pin holes on the stator punch overlap to form the positioning holes of the stator core.

[0063] 3) The two motor end covers 6 are respectively placed at both ends of the stator core. Each of the four corners of the motor end cover 6 has a screw hole 601 and a pin hole 602 respectively.

[0064] 4) After inserting a positioning pin 7 from any pin hole 602, it is inserted into the pin hole of the stator core. Locating pin 7 and the positioning hole on the stator punching sheet are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com