Automobile crankshaft oil seal of novel structure

A new type of structure and automobile technology, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of large rubber friction coefficient, short working life and low strength of rubber oil seals, and achieve high temperature resistance and chemical corrosion. , Good automatic wear compensation ability, chemical corrosion resistance and self-lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

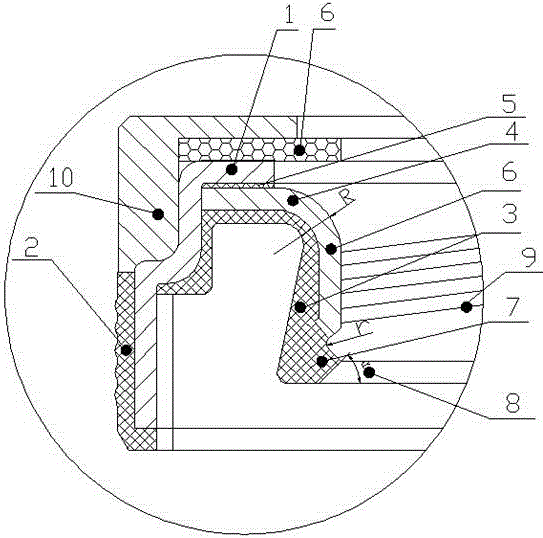

Image

Examples

Embodiment 1

[0024] Embodiment 1: The installation framework of this oil seal is a circular metal framework 1 with a two-layer stepped cross-section, and a vulcanized rubber covering layer 2 is attached to the vertical surface and bottom surface of the lower step of the outer ring of the circular metal framework 1. The lower step surface of the inner ring of the skeleton 1 and the vertical surface of the upper step are attached with a rubber-made sealing lip support body 3 with an n-shaped cross-section, and the surface of the middle inner ring of the sealing lip support body 3 is provided with filling modification. PTFE surface sealing lip 4, an elastic conveying rubber layer 5 is provided between the filled modified PTFE surface sealing lip 4 and the lower end surface of the upper step surface of the annular metal frame 1, which is filled with modified The contact surface of the annular sealing cylinder surface 4 of the main lip of the polytetrafluoroethylene seal and the sealing lip supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com