Axle sealing oil-seal and seal lip material thereof

A shaft seal and sealing lip technology, applied in the field of shaft sealing devices, can solve the problems of oil seal damage, easy damage or peeling of polytetrafluoroethylene sealing lip, leakage of lubricating oil, etc., and achieves firm assembly, good automatic compensation ability, and high temperature resistance. And the effect of strong chemical corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

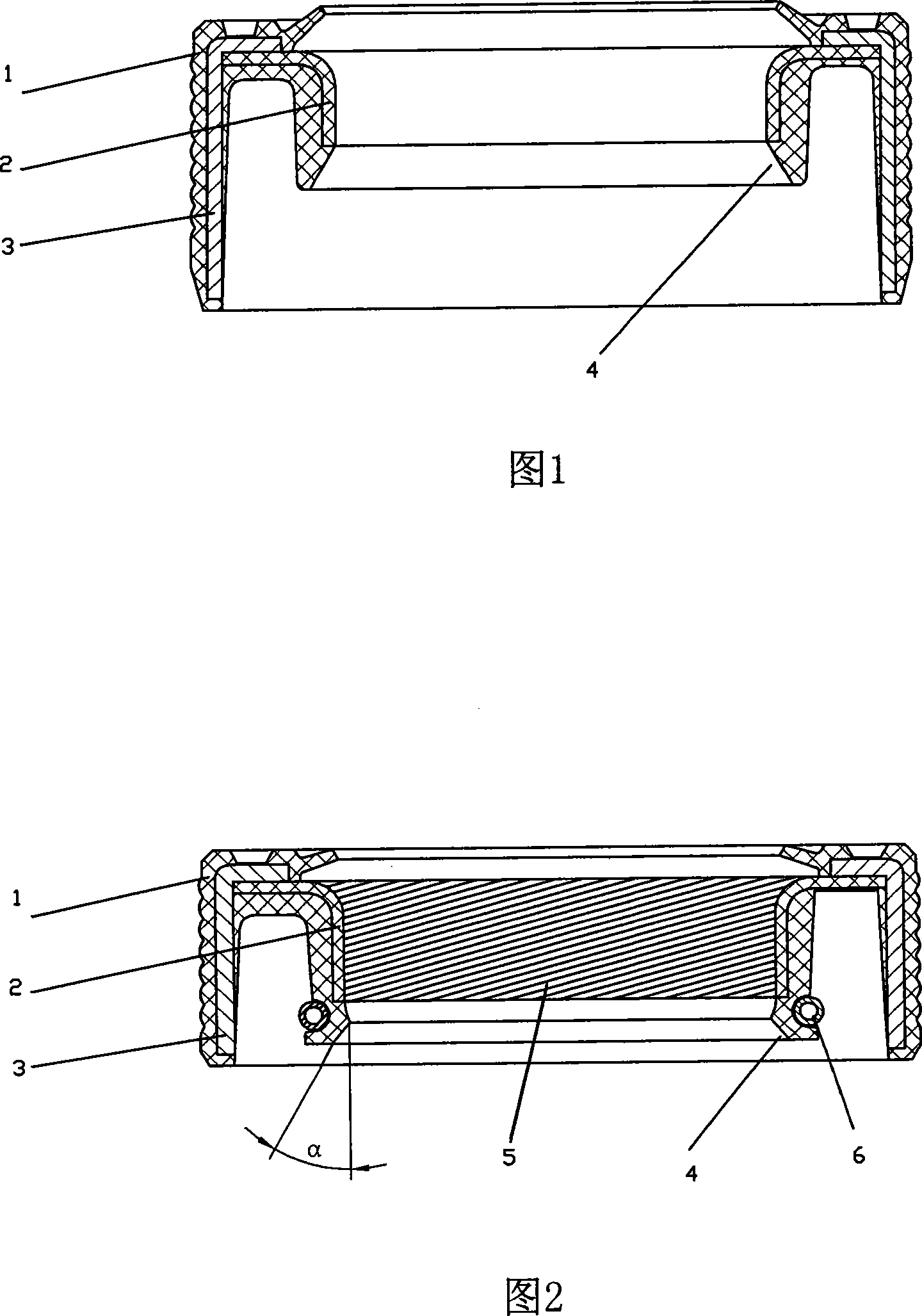

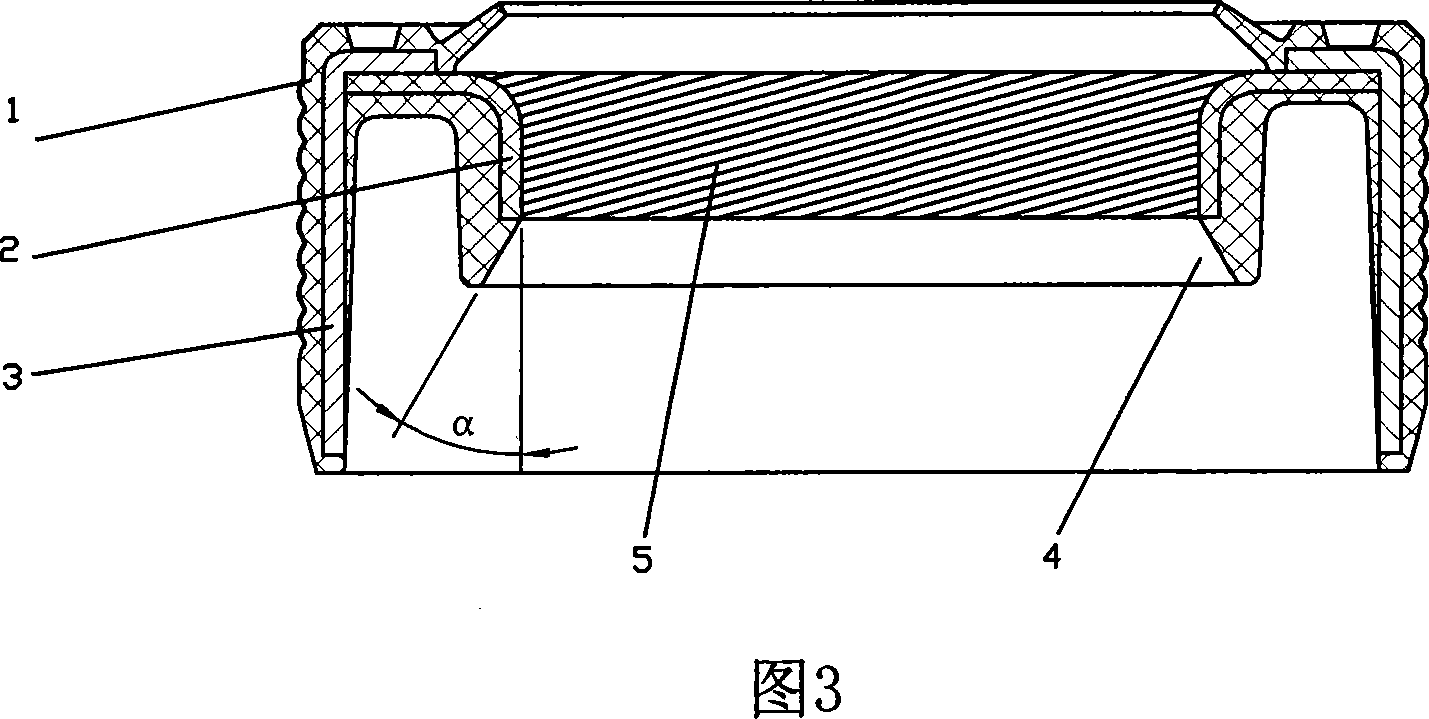

[0028] Fig. 1 is the structural representation of the present invention, and the novel shaft sealing oil seal of the present invention comprises rubber body 1, skeleton 3, polytetrafluoroethylene sealing lip 2 and auxiliary lip; Suspended polytetrafluoroethylene resin 75%, polyparaben 10%, glass fiber 10%, chromium oxide 5% new filled polytetrafluoroethylene, this new material has good self-lubricating performance, high temperature resistance and The chemical corrosion ability is strong; the material of the skeleton 3 is metal iron with phosphating treatment on the surface; the end of the sealing lip 2 is bent outward, and the bent end is pressed between the rubber body 1 and the skeleton 3, and the skeleton 3 And sealing lip 2 and rubber body 1 are vulcanized and integrated, and the contact surface of sealing lip 2 and rubber body 1 is chemically treated with sodium and ammonia solution or naphthalene and sodium complex before vulcanization molding to make them firmly bonded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com