Shutter cleaner

A technology of washer and louver, which is applied in the direction of cleaning the stomach of slaughtered livestock, cleaning the intestines, slaughtering, etc., and can solve the problem of not being able to completely clean the folds and dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

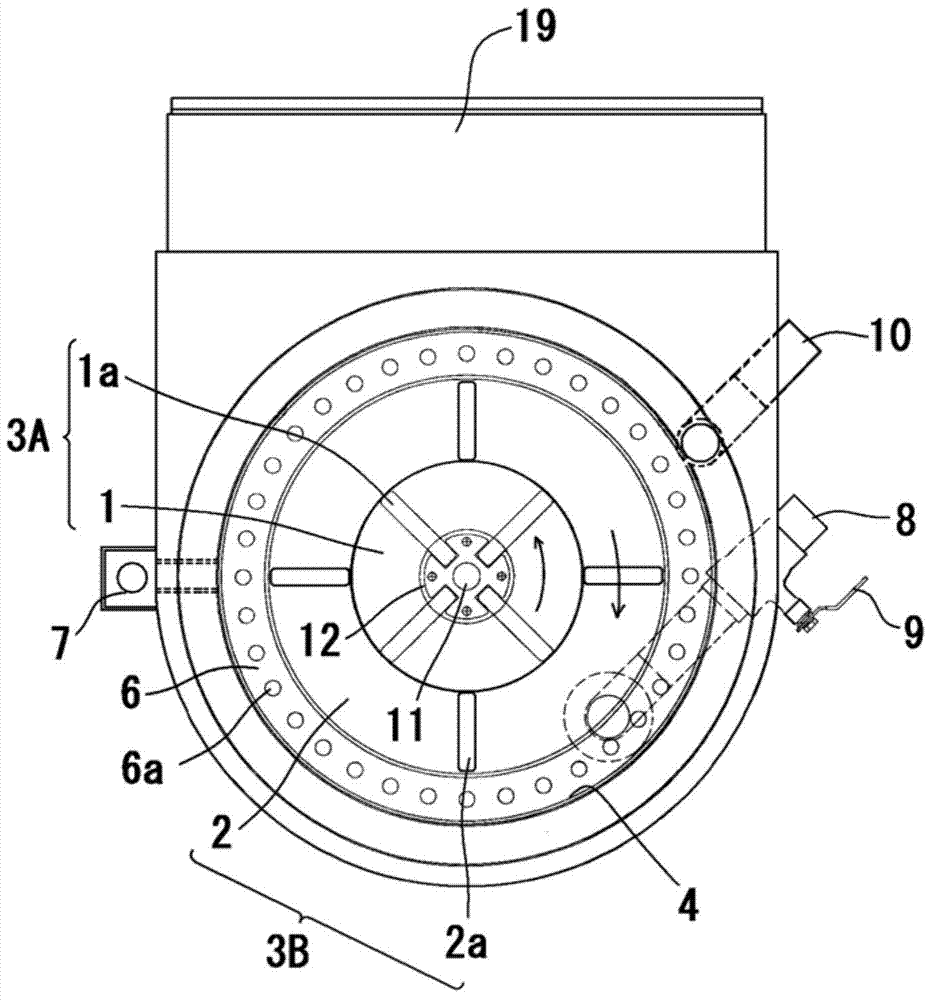

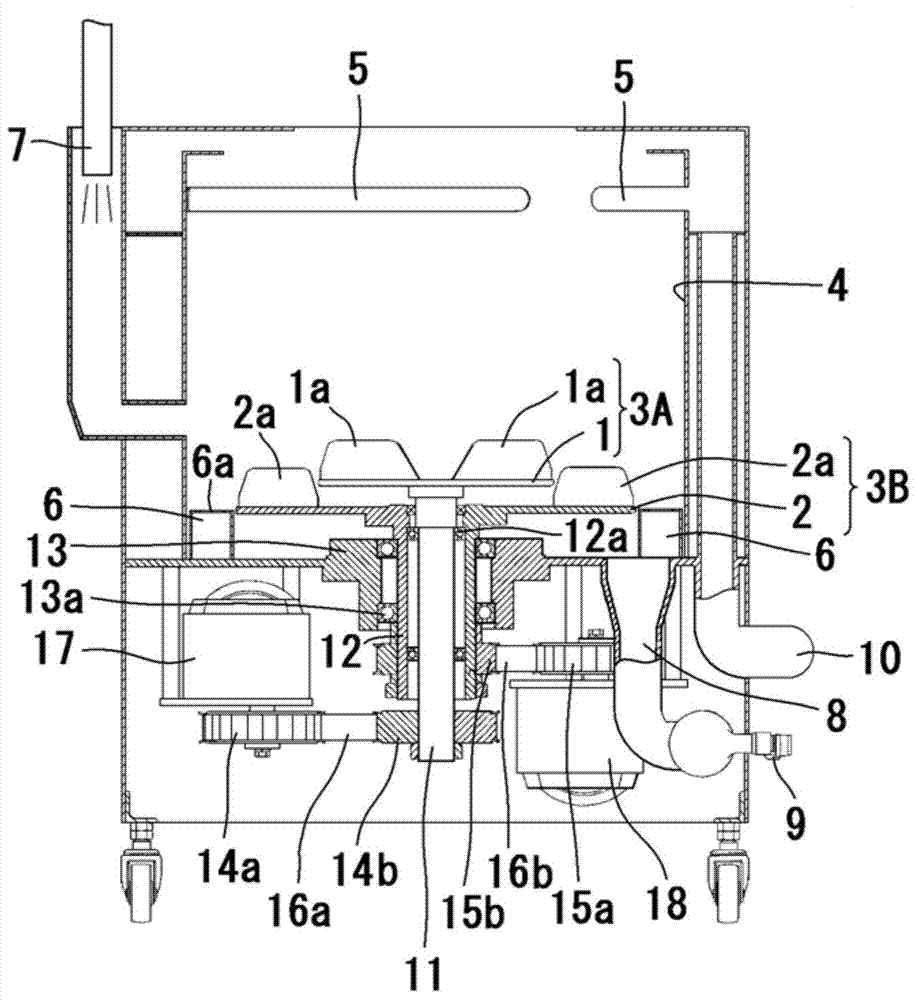

[0016] like Figure 1 to Figure 2 As shown, the louver washer of the present invention is equipped with a first agitator 3A and a second agitator 3B with different outer diameters at the inner bottom of a drum-shaped washing tank 4 with an open upper surface. The first agitating body 3A arranged on the outer side has a plurality of agitating blades 2a upright on the rotating disc 2, and a hollow shaft cylinder 12 is integrally formed from the central lower end thereof, and the hollow shaft cylinder 12 is rotatably supported on the washing tank. The bearing 13a on the housing 13 of 4.

[0017] On the other hand, the second stirring body 3B has a plurality of stirring blades 1a erected on the rotating plate 1, and its rotating shaft 11 is inserted into the hollow shaft cylinder 12, and is rotatably supported in the hollow shaft cylinder 12. The bearing 12a. The internal and external agitating bodies, that is, the first agitating body 3A and the second agitating body 3B are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com