A rpc (reactive Powder Concrete)-ordinary concrete composite section structure

A common concrete and composite cross-section technology, applied in the field of RPC (Reactive Powder Concrete)-ordinary concrete composite cross-section structure, can solve problems such as few, temporary but not permanent, and inconspicuous actual effects, and achieve reduced creep deformation and high Compressive strength properties, effects evident from the distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

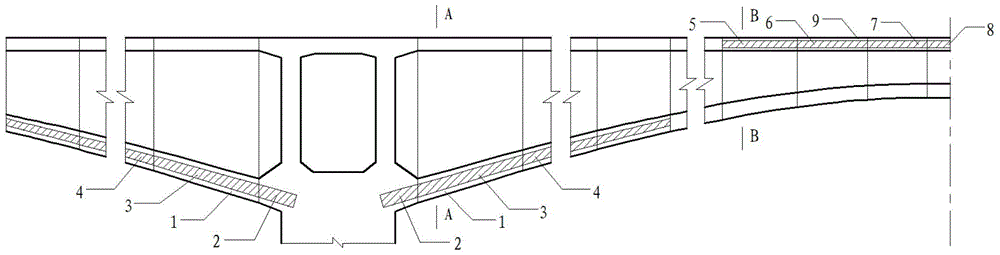

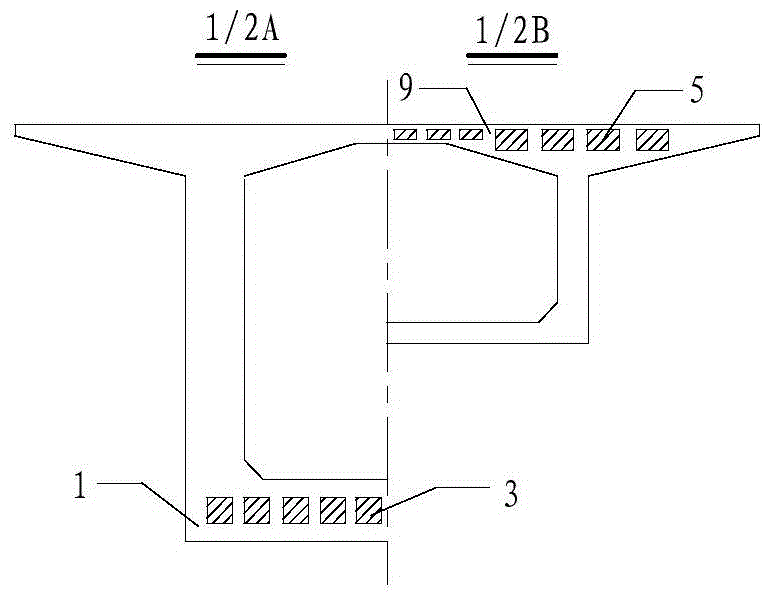

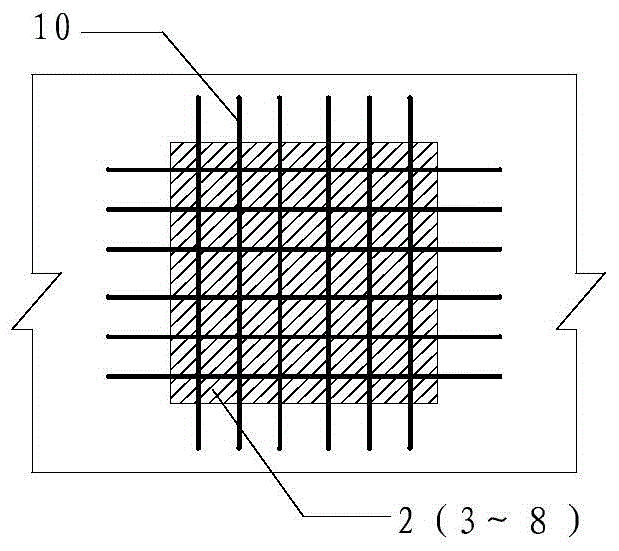

[0025] Such as Figure 1~Figure 3 As shown, the present invention mainly relates to cast-in-place ordinary concrete box girder bottom plate (1), cast-in-place ordinary concrete box girder top plate (9), prefabricated RPC columns 1-7 (2-8), and steel bar shear keys (10). During the construction of the actual bridge, prefabricated RPC columns 1~7 (2~8) first; before casting the No. 0 block of the box girder bridge, put the prefabricated RPC column 1 (2) in the formwork; pass between concrete and precast RPC columns 1 (2) image 3 The steel bar shear key (10) in the bridge is connected; before the No. 1 cast-in-place block, the prefabricated RPC column 1 (2) and the prefabricated RPC column 2 (3) are connected by glue; after that, the No. 1 block of the cast-in-place box girder bridge. Similarly, block No. 2~1 / 3n of the box girder bridge (n is the number of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com