Highly wear-resistant sliding plate for support of bridge

A high wear-resistant technology for bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of small bearing capacity per unit area, difficult support maintenance, poor self-lubricating performance, etc., achieve small creep deformation, save energy The amount of steel used and the effect of good self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

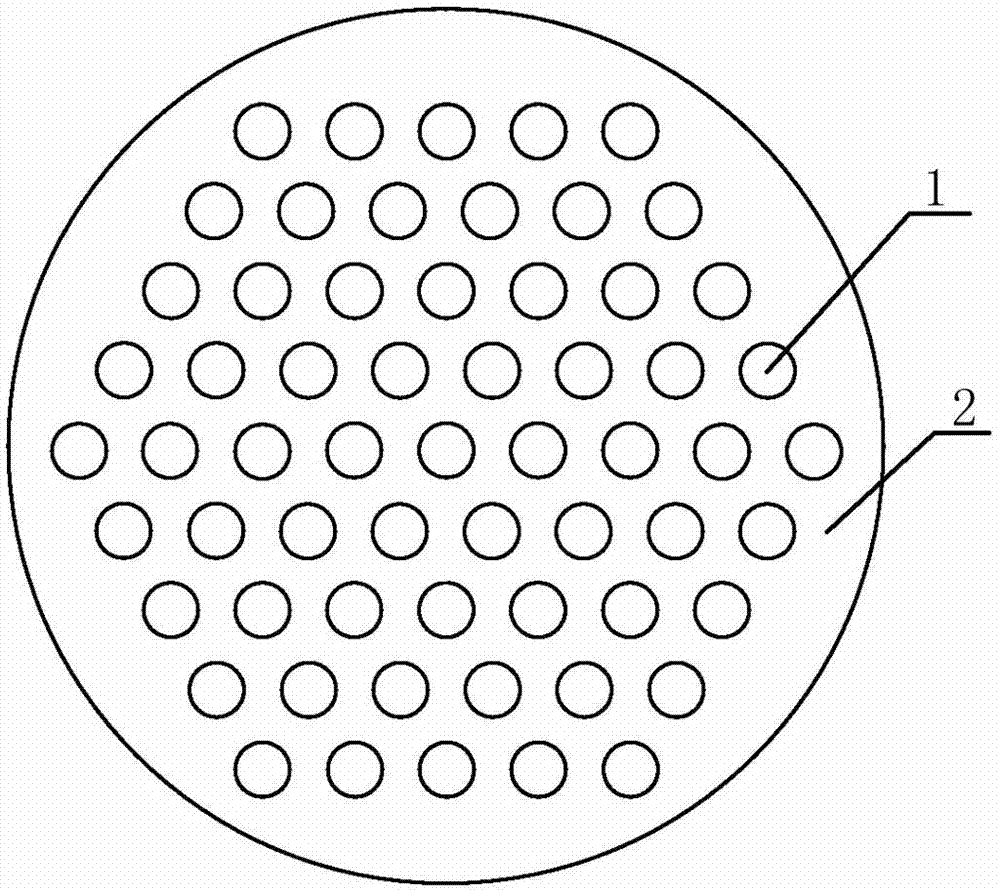

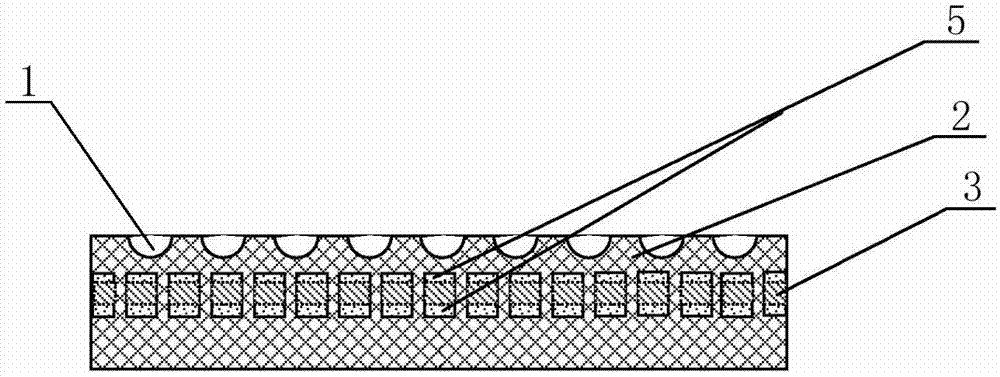

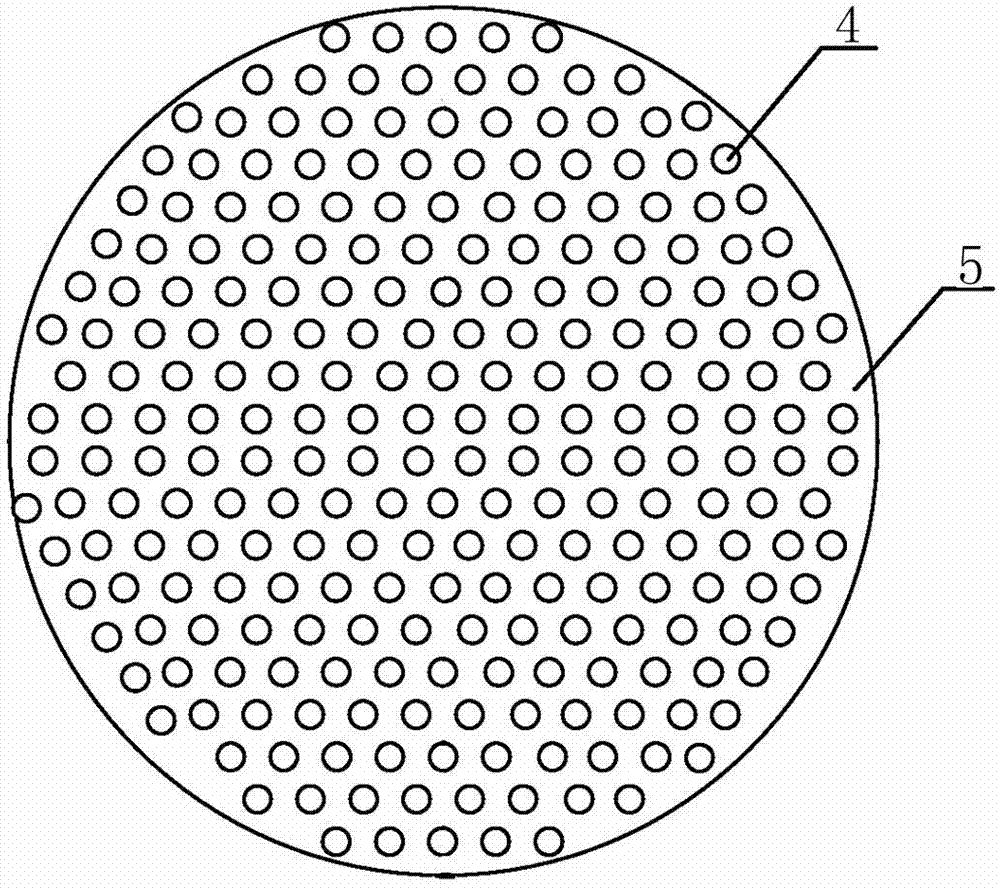

[0020] As shown in 1, 2, 3, and 4 in the accompanying drawings, it is a specific embodiment of the present invention, which is composed of a metal skeleton disc 3 and a fluoroplastic alloy material disc 2 arranged on the metal skeleton disc 3, and the metal The skeleton circular plate 3 is provided with a pore structure, that is, a through hole 4 is provided. In the present invention, an oil storage groove 1 is arranged on the surface of a circular plate 2 made of fluoroplastic alloy material. The metal skeleton circular plate 3 of the present invention can use surface sintered metal powder, that is, a metal powder layer 5 is arranged on the surface of the metal skeleton circular plate 3 . The metal frame circular plate 3 punches and presses holes, that is, the metal frame circular plate 3 is provided with a pore structure, that is, a through hole 4 is provided.

[0021] The invention is composed of a built-in metal skeleton circular plate 3 and an external fluoroplastic allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com