Self-returning lead extruding damper

A self-reset, damper technology, applied in building components, earthquake-proof and other directions, can solve the problems of not being able to restore to the original position, unfavorable structural performance requirements of residual deformation, and less research on energy consumption in two-dimensional space, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A self-resetting lead squeeze damper of the present invention will be described in detail below in conjunction with the embodiments and drawings.

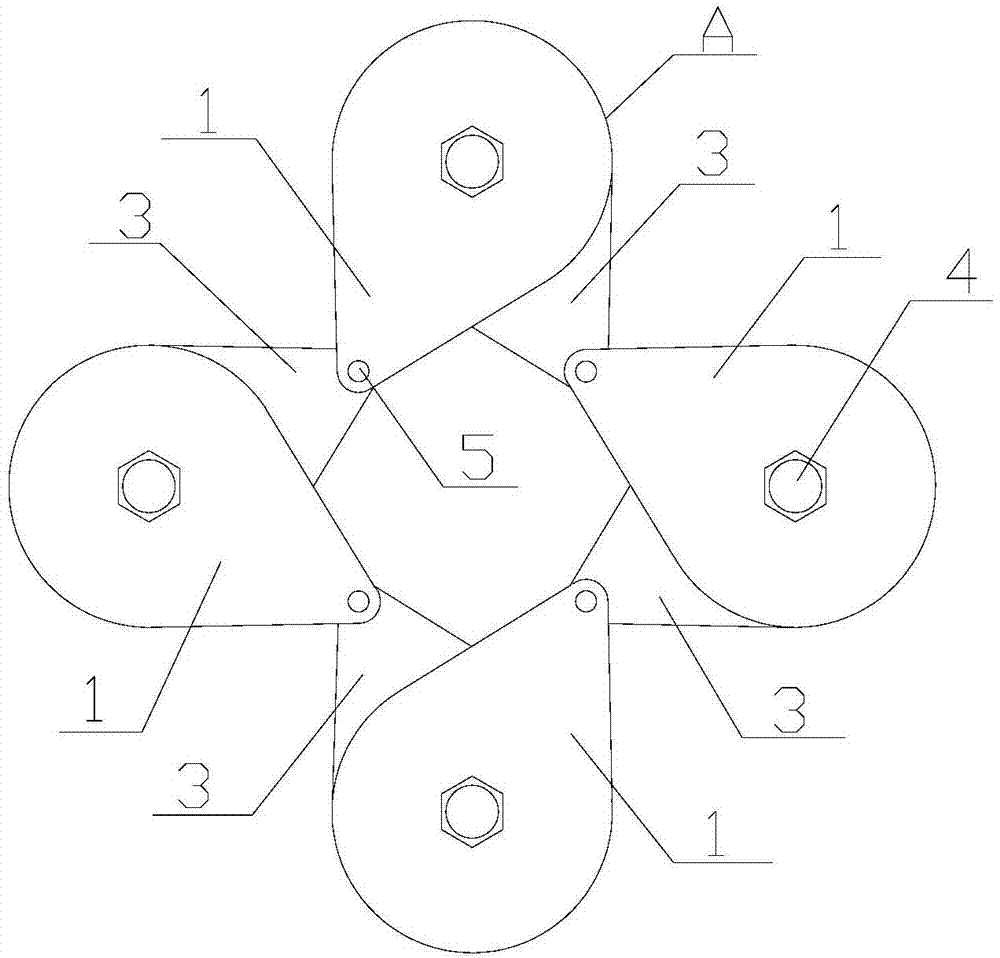

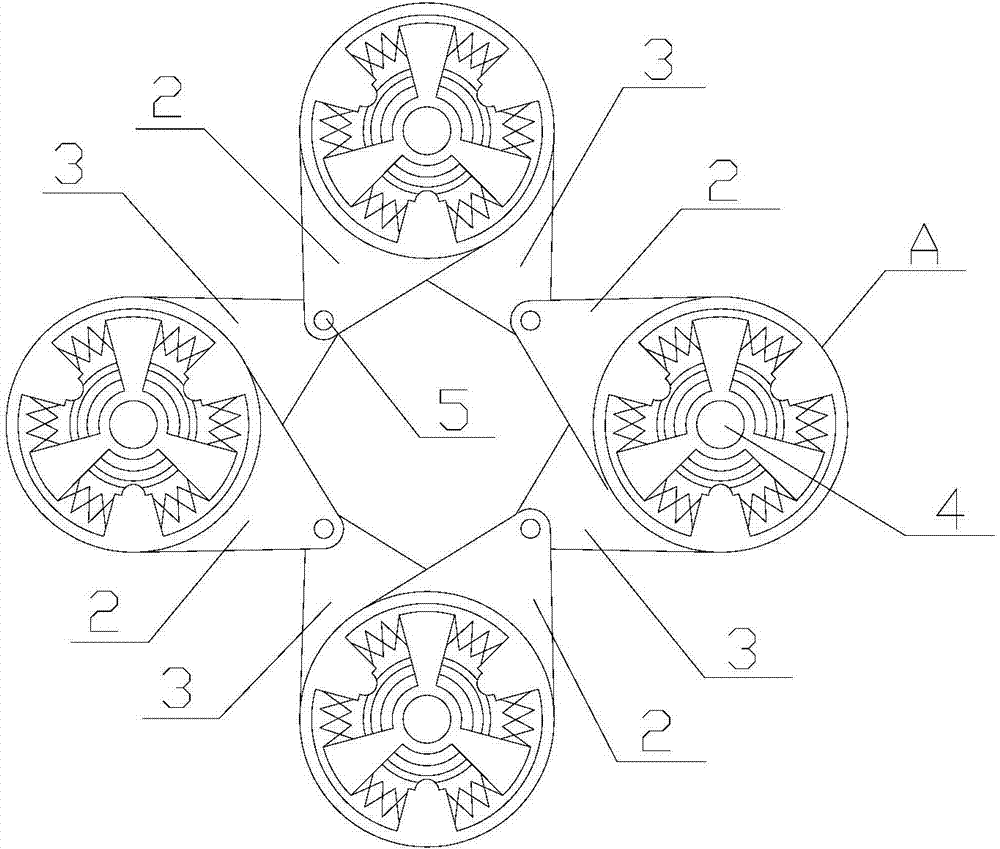

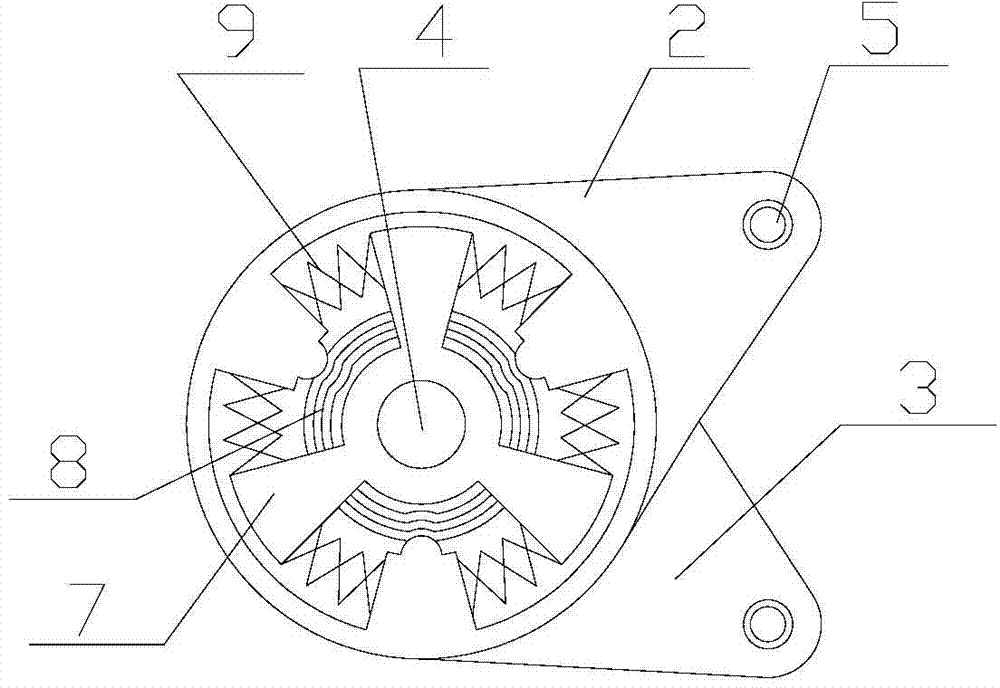

[0032] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 8 As shown, a self-resetting lead extrusion damper of the present invention is a ring-shaped position-limiting structure composed of four groups of damping units A with the same structure hinged sequentially through connecting pin shafts 5. The damping unit A includes The upper plate 1, the middle plate 2 and the bottom plate 3 are sequentially connected through the pin shaft 4 from top to bottom, and the upper plate 1 and the bottom plate 3 are provided with a No layer of adhesive material. like Figure 5 , Figure 6 As shown, the main body of the upper plate 1, the middle plate 2 and the bottom plate 3 is a circular structure, and a connecting handle 6 is integrally formed on the side of the circular structure, and the handle 6 must ensure sufficient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com