A visual inspection method and device for root cleaning of crankshaft shoulder

A visual inspection and shaft shoulder technology, applied in measuring devices, optical devices, instruments, etc., can solve the problems of high inspection cost, low inspection accuracy, long inspection time, etc., achieve efficient identification and inspection, enhance anti-interference, The effect of reducing inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

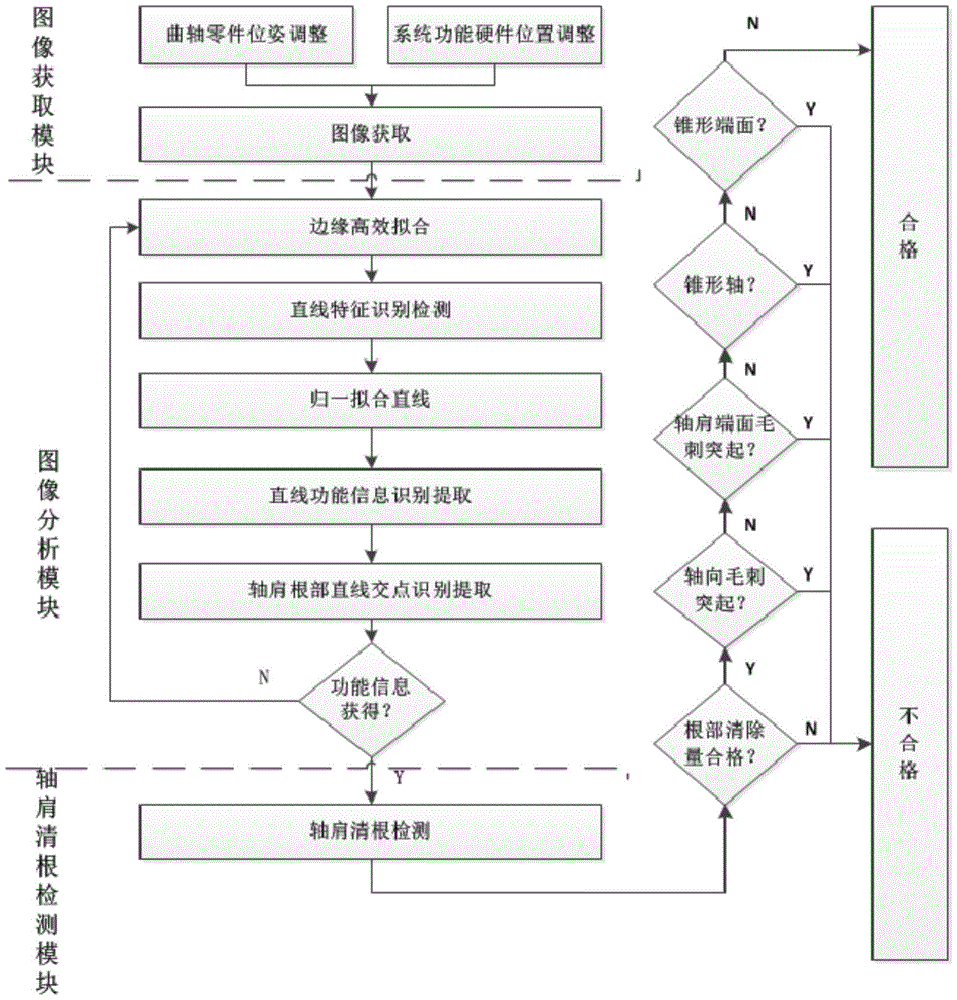

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

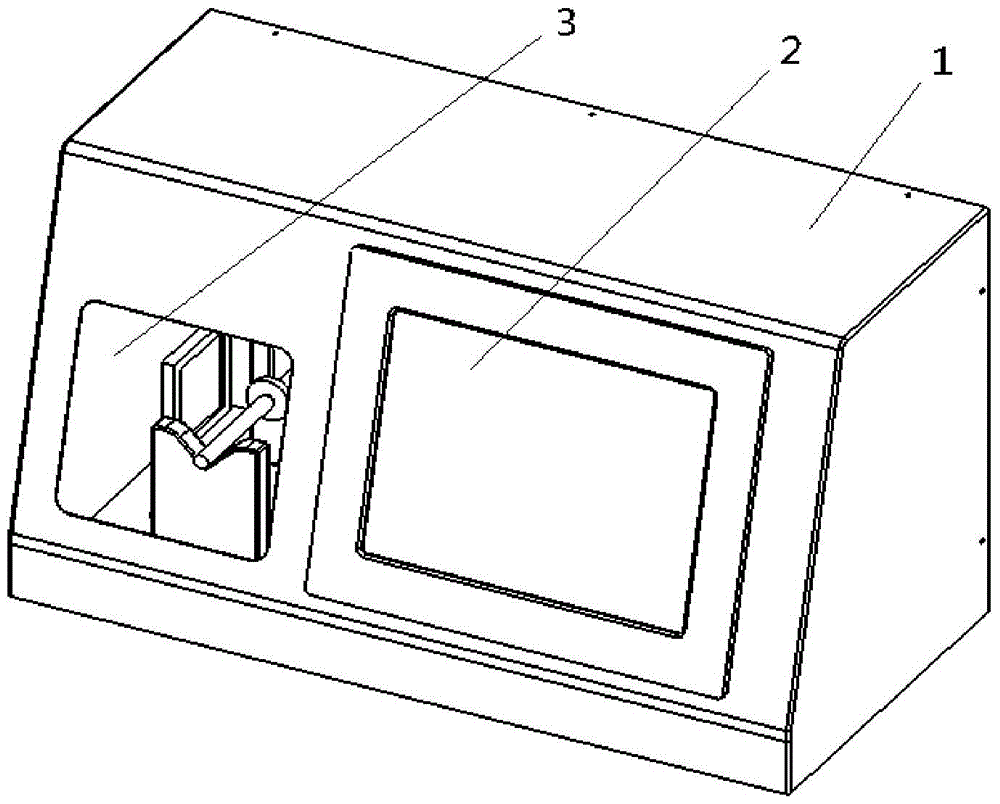

[0042] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

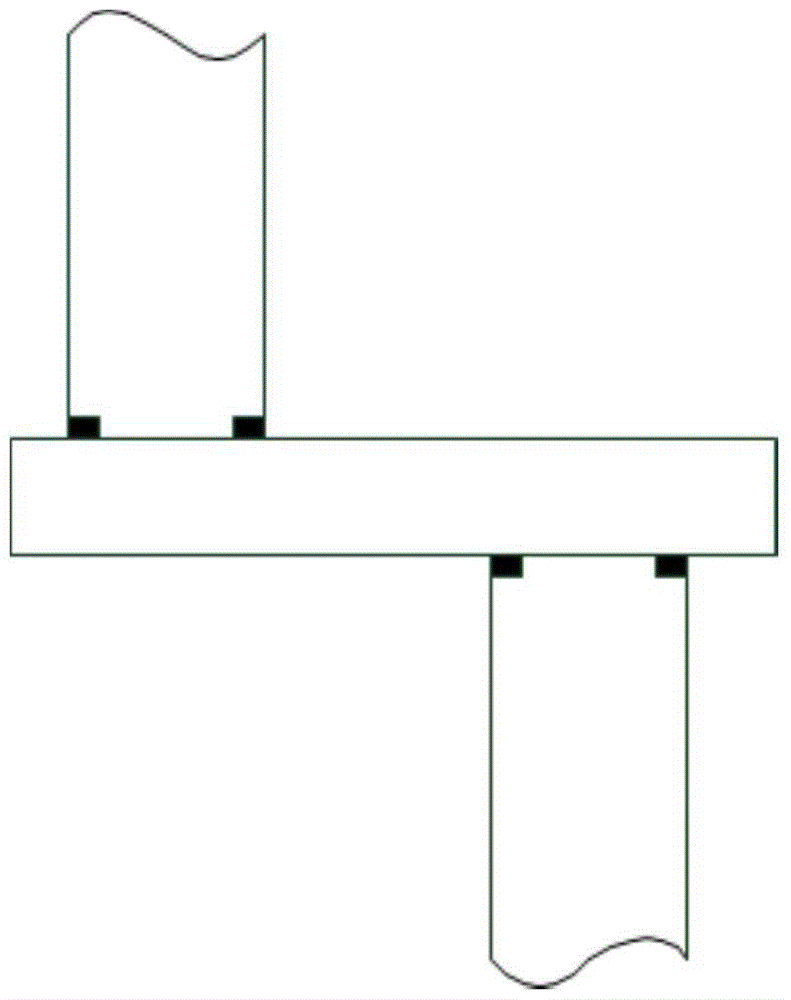

[0043]For crankshaft parts on the engine, its positioning shoulder needs to be close to the end face of the bearing to meet the product requirements. Such a crankshaft has powerful functions and requires high processing parameters, and is a key part of the engine. After the rough machining process is completed, the crankshaft is generally ground and cleaned with a special grinding wheel. It mainly has the following two functions: firstly remove the processing redundancy such as root protrusions and burrs, and further remove a certain amount of material at the root to ensure the close fit between the shaft shoulder end face and the bearing end face. The second is the finishing of the curved surface of the crankshaft to meet the matching requirements with the inner ring of the bearing.

[0044] Through industrial field research, it was conclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com