Spin-free stepless transmission unit

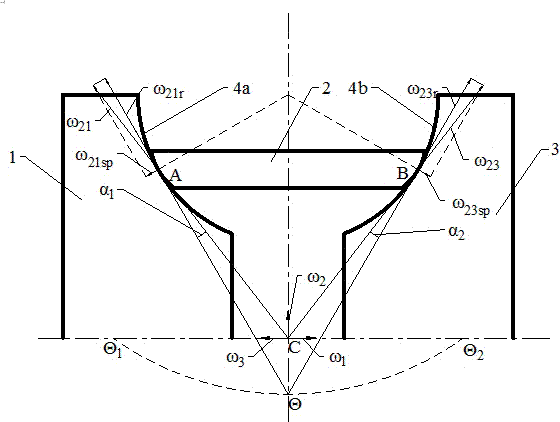

A continuously variable speed unit, non-spin technology, applied in the direction of friction transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of reduced traction efficiency, softening of workpiece surface, rising oil temperature, etc., to achieve no spin EFFECT OF EFFICIENCY LOSS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

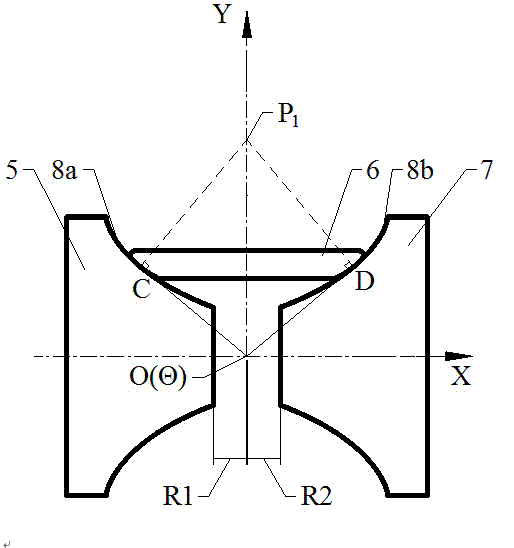

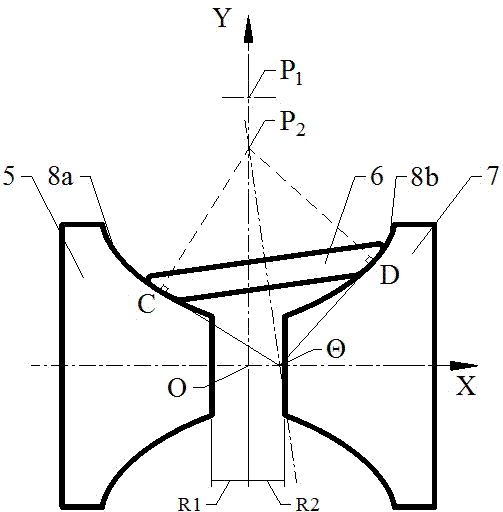

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] Due to the special curved surface shape of the non-spin stepless transmission unit, the main components in the transmission unit need to adjust their positions during the speed adjustment process, so a state must be determined to determine the origin position. When the transmission ratio is 1, the position of each component in the entire transmission unit is relatively special, so for the convenience of description, the transmission state diagram of the non-spin continuously variable transmission unit when the transmission ratio is 1 is in figure 2 shown in . The non-spin input cone 5 and the non-spin roller 6 are pressed tightly on the contact point C, and the non-spin output cone 7 and the non-spin roller 6 are pressed tightly on the contact point D, forming The oil film transmits power by the rotation of each component. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com