Self-rotation free multi-rolling-cone type stepless speed change unit

A continuously variable transmission unit, no spin technology, applied in the transmission device, friction transmission device, belt/chain/gear, etc. performance, speed control troubles and other issues, to achieve the effect of simple speed control, easy control, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

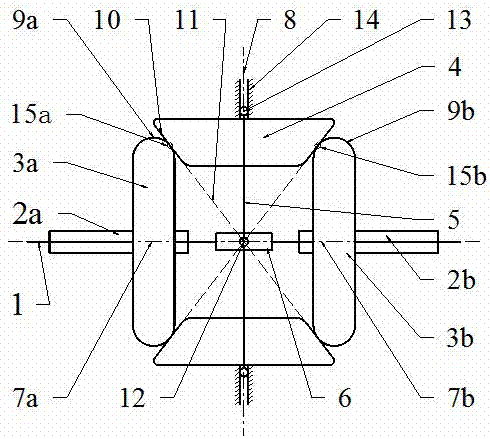

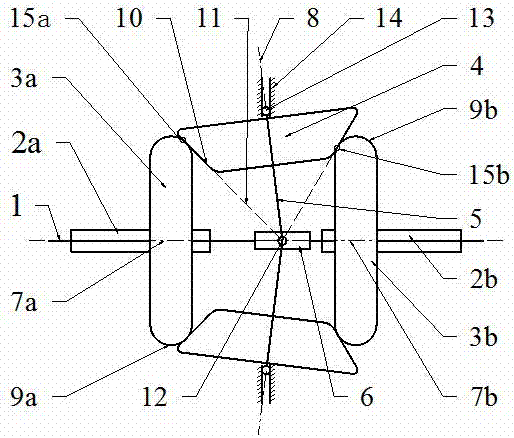

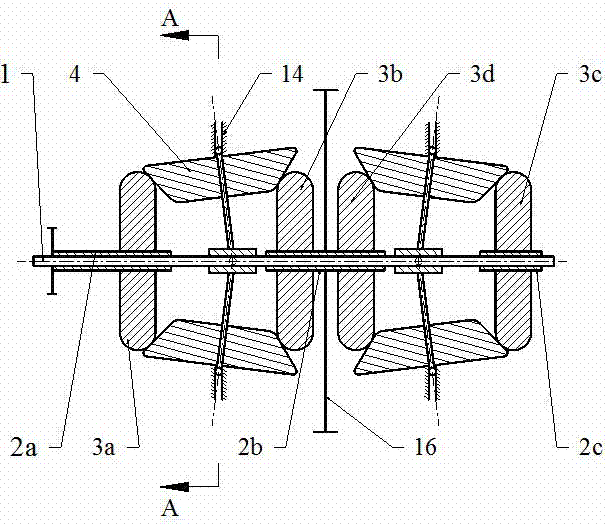

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] as attached figure 1 As shown, the present invention provides a non-spin multi-roller cone type continuously variable transmission unit, which mainly consists of a spindle (1), an input bushing (2a), an output bushing (2b), an input roller (3a), an output roller (3b), the force transmission roller cone (4), the roller cone installation shaft (5), and the speed regulating bushing (6).

[0036] During transmission, the power is transmitted from the input bushing (2a), thereby driving the input bushing (2a) to rotate together with the input roller (3a), and the input roller (3a) pulls the force transmission roller cone (4) to rotate, and the power is transmitted by the force transmission The rolling cone (4) is transmitted to the output roller (3b) and then to the output bushing (2b) for final output.

[0037] The input bushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com