A kind of non-spin stepless transmission and its speed regulating device

A technology of continuously variable transmission and speed regulating device, which is applied in the direction of transmission device, friction transmission device, belt/chain/gear, etc. It can solve the problems of complex control and achieve the effect of simple control mode and no loss of spin efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

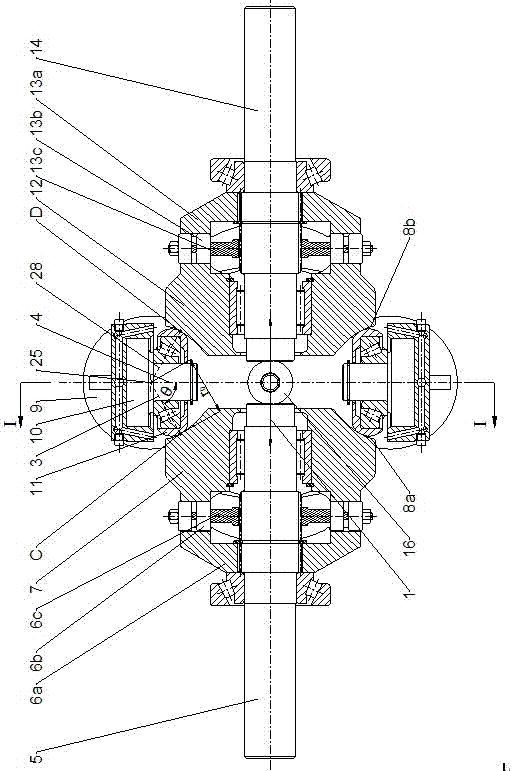

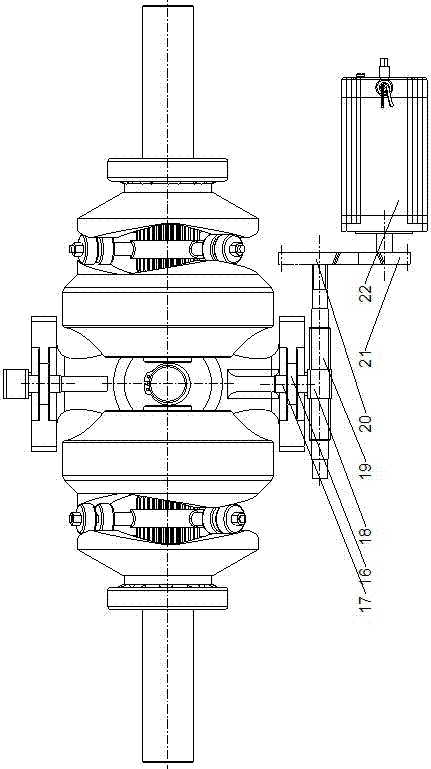

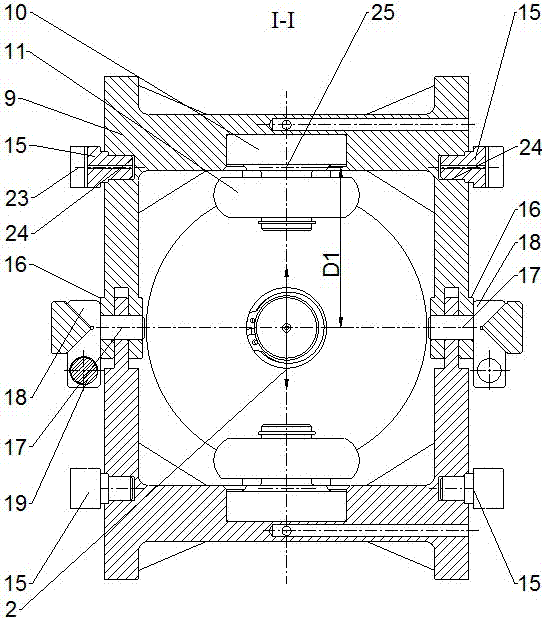

[0013] figure 1 The main sectional view of the non-spin continuously variable transmission is shown. As shown in the figure, in this scheme, an input shaft cam 6a is installed on the input shaft 5, and the input shaft cam 6a, the input shaft cam roller 6b, and the input shaft roller frame 6c form an input shaft axial pressure device. To provide axial force to the non-spin input cone 7 to ensure that it maintains pressure contact with the non-spin roller 11 at the input point C, the non-spin roller 11 is installed on the roller shaft 10, and the roller shaft 10 is fixedly installed On the trunnion 9, it can finally ensure that the position of the non-spin roller 11 relative to the trunnion 9 remains fixed, and the non-spin roller 11 can still rotate around its own roller rotation axis 4; on the other side, the output shaft 14 is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com