Fuse protection structure

A protection structure, fusing technology, applied in heating/cooling contact switches and other directions, can solve the problems of low safety factor, complex overall structure layout, difficult assembly, etc., to reduce maintenance and repair costs, improve layout rationality, and ensure safe use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

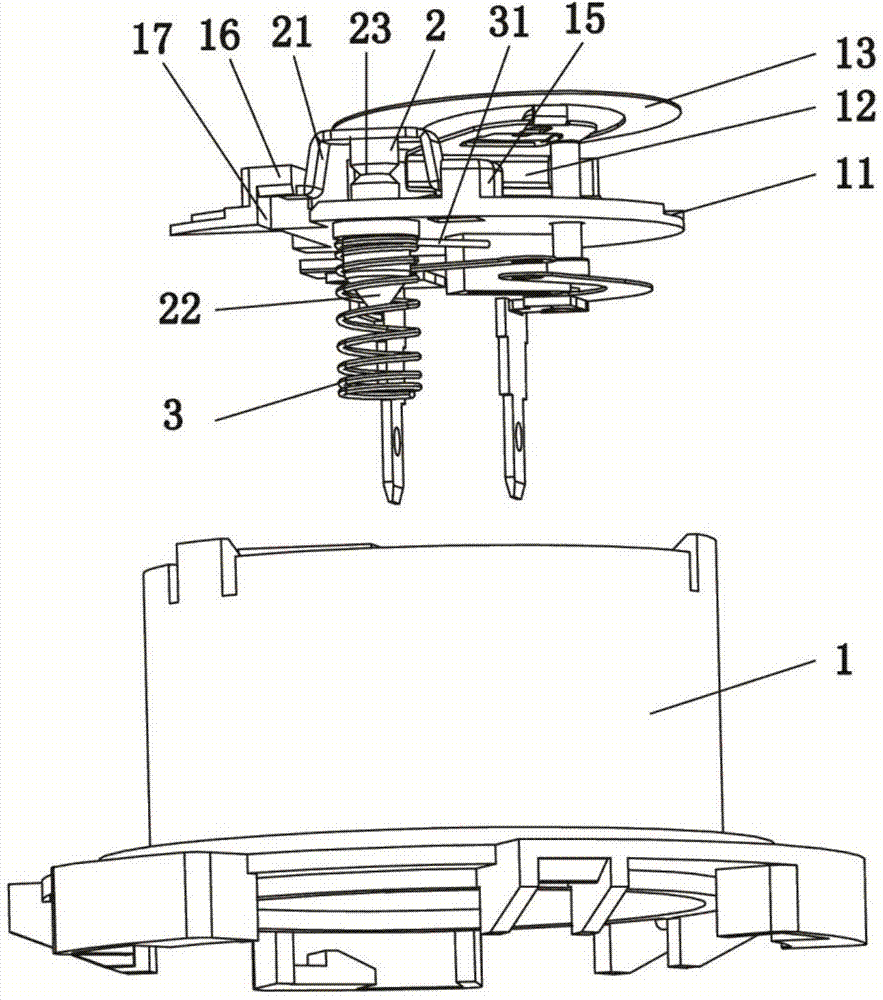

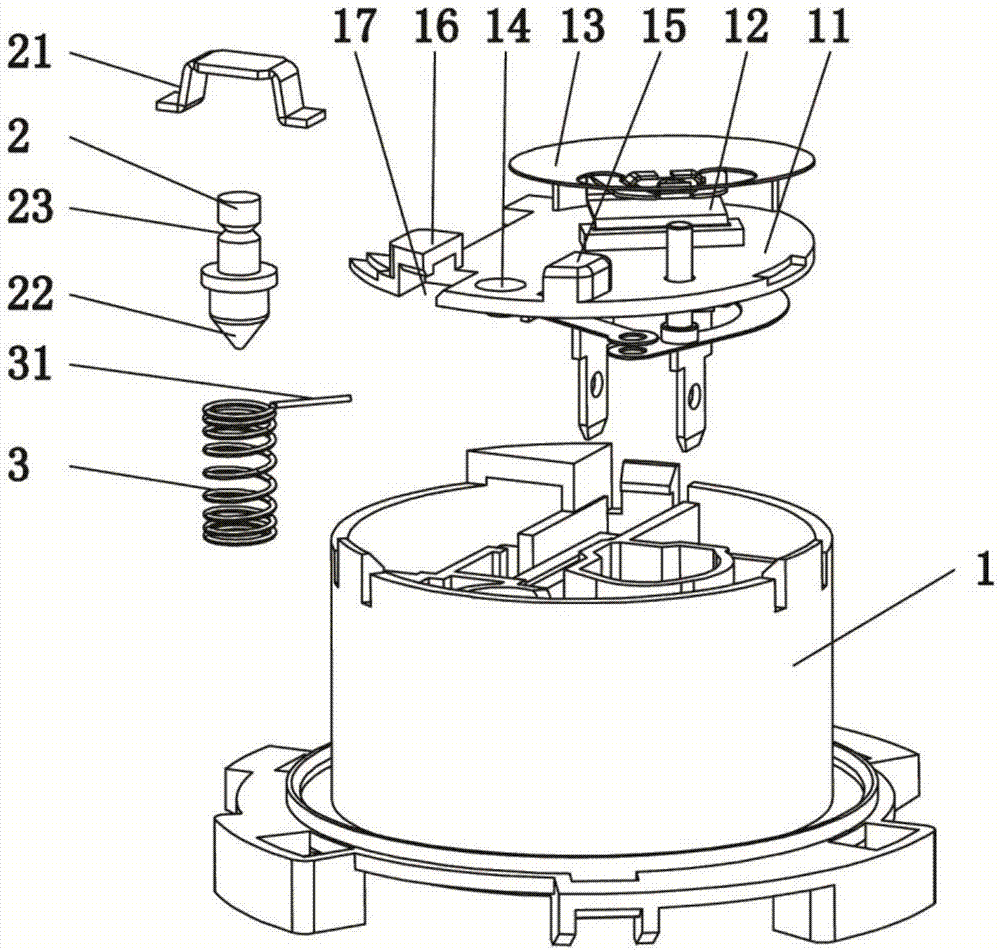

[0021] A fusing protection structure according to the present invention includes a base 1 and a fixed plate 11, the fixed plate 11 is provided with an elastic reed 12, and the free end of the elastic reed 12 is provided with a temperature sensing sheet 13, the fixed The plate 11 is provided with a through hole 14, the through hole 14 is pierced with a fuse core 2, the upper end of the fuse core 2 is provided with a temperature sensing plate 21, the temperature sensing plate 21 is movably connected with the fixed plate 11, and the lower end of the fuse core 2 is connected to the base 1. A support spring 3 is provided between them, and a shift fork 31 is provided between the support spring 3 and the fuse core 2 . The above-mentioned components are the main structure of the present invention, the fixed plate 11 is installed on the upper end of the base of the sensor, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com