Touch substrate, display device, manufacturing method and driving method thereof

A technology for display driving and touch driving electrodes, which is applied in the fields of optics, instruments, electrical digital data processing, etc., can solve problems such as unsatisfactory requirements, and achieve the effect of saving electrode layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

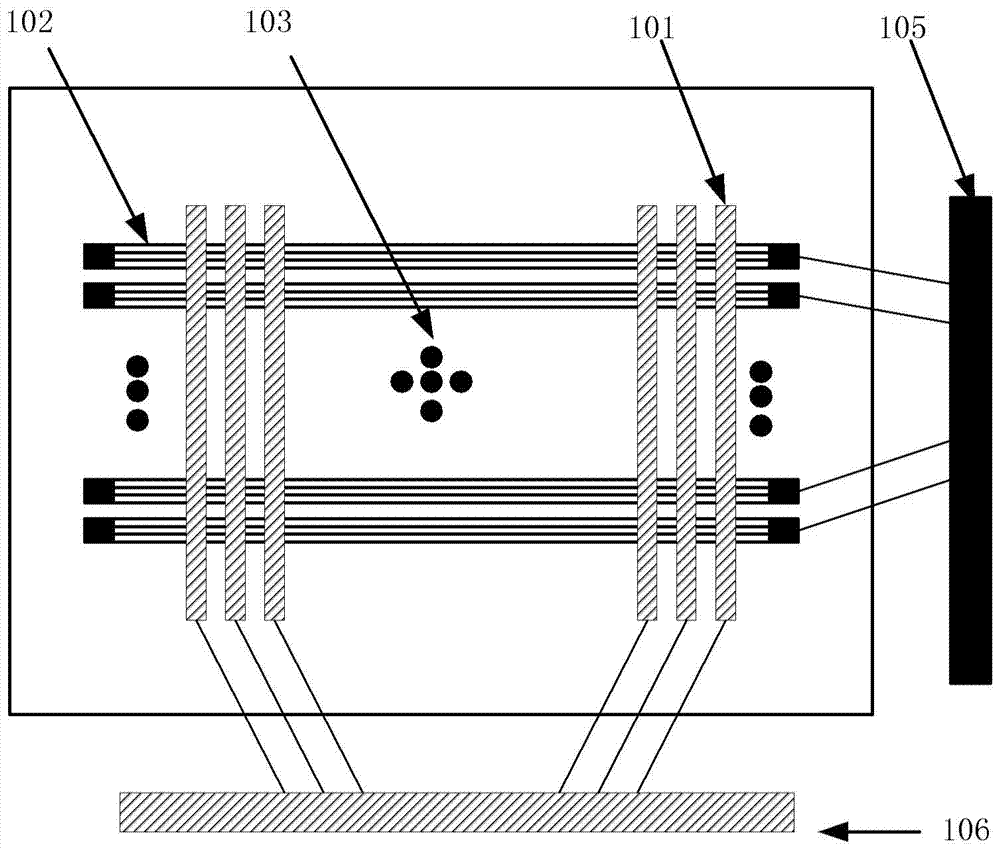

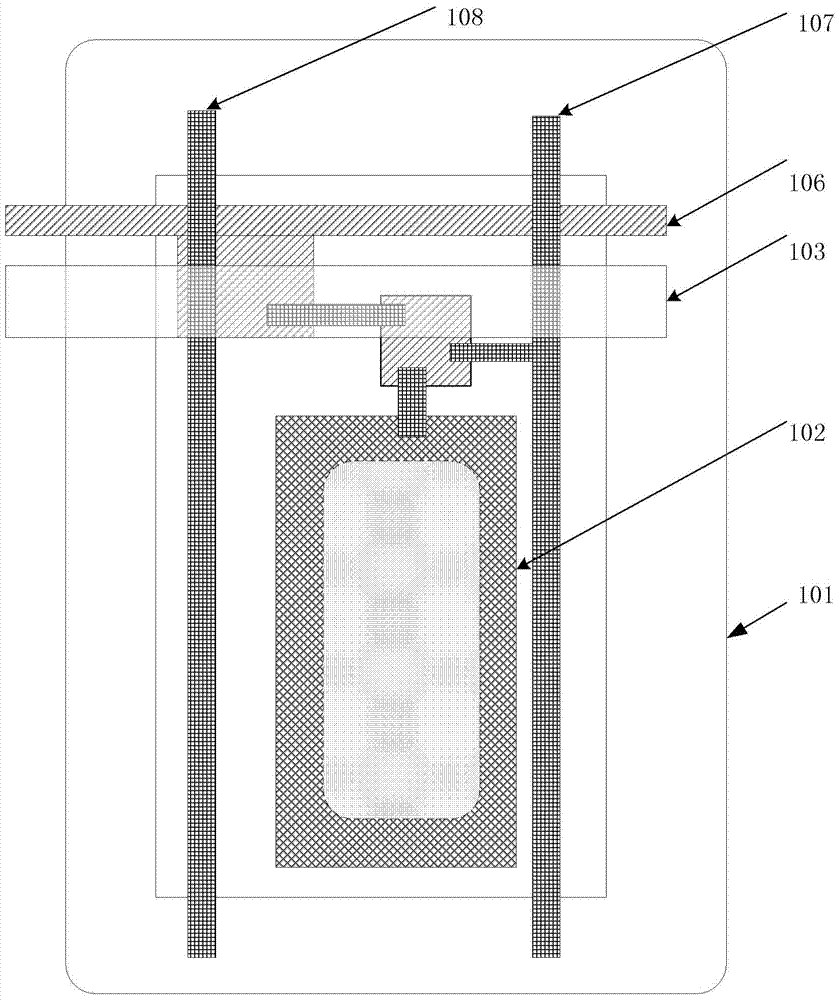

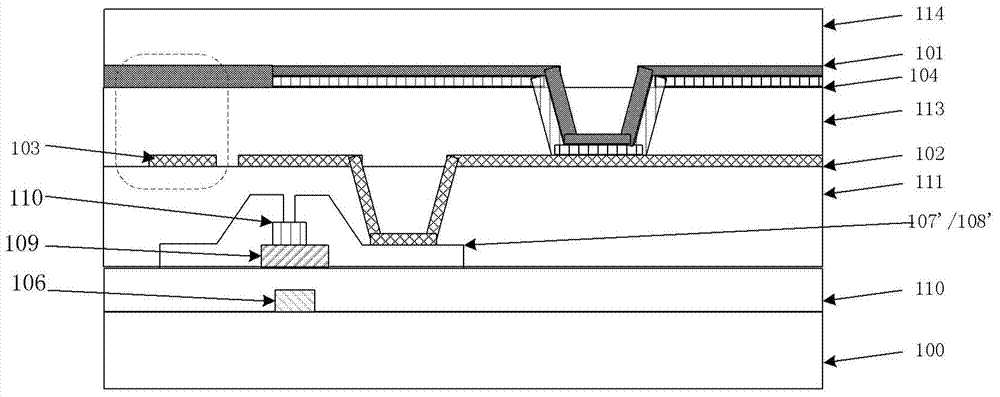

[0022] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings, wherein like numerals refer to like elements throughout. The following embodiments will be described by referring to the figures in order to explain the present invention.

[0023] The basic scheme of the present invention is to use the anode and cathode layers of the OLED device as the electrode layer of the touch sensor, that is, the cathode is patterned and then used as the sensing electrode Rx of the sensing layer of the touch sensor, and is arranged on the substrate in conjunction with the touch sensor. At least one touch drive electrode set on the same layer as the anode is used as the drive electrode Tx of the touch sensor; and then the OLED drive operation and touch sensing operation are performed through time-sharing driving to complete this integrated in-cell touch display touch and display operations. The solution of the embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com