Method for diagnosing fault of fire pump based on acoustic emission signals

An acoustic emission signal, fault diagnosis technology, applied in pump testing, machine/engine, liquid variable capacity machinery, etc., can solve the problem of undetectable fault characteristic frequency of fire pump, difficult to accurately evaluate the working state of fire pump, fault detection Difficulty and other problems, to achieve the effect of eliminating distorted signal components, strong anti-noise interference ability, and obvious characteristic frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

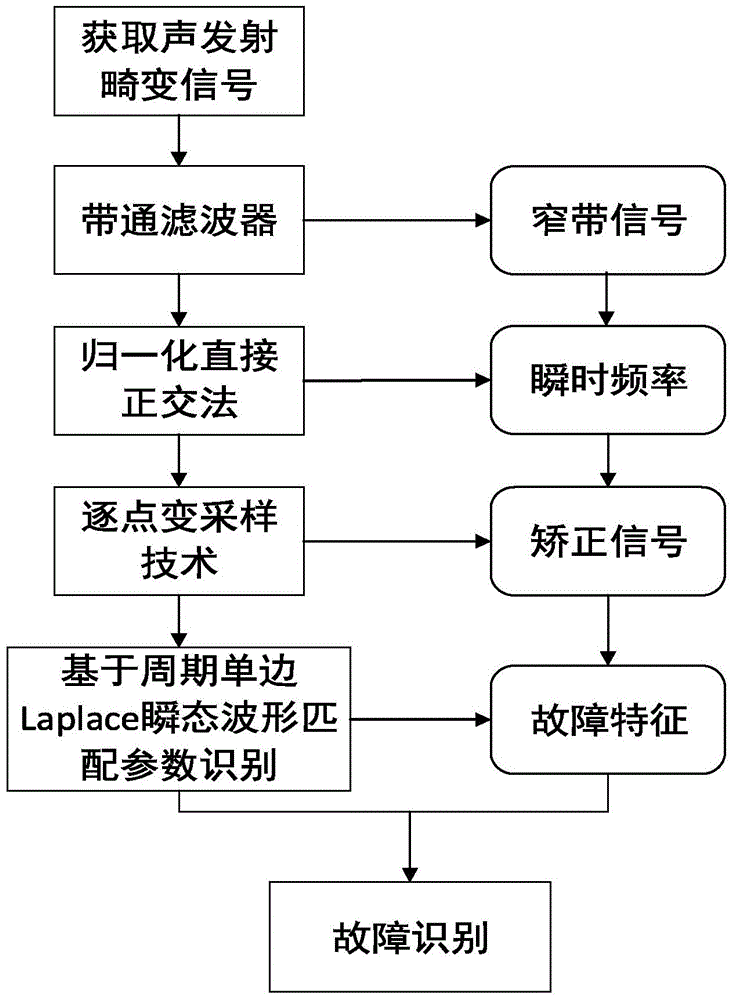

[0025] figure 1 It is a flowchart of the method of the present invention, the method may further comprise the steps:

[0026] Step 1: Use the acoustic emission sensor to detect the signal of the fire pump, and collect the acoustic emission signal with distortion characteristics of the fire pump in the running state;

[0027] Step 2: Use a band-pass filter to extract the narrow-band signal in the acoustic emission signal, perform normalized direct orthogonal calculation on the narrow-band signal to obtain its instantaneous frequency, and finally perform point-by-point sampling correction on the signal based on the obtained instantaneous frequency. Obtain a corrective signal;

[0028] Step 3: Use the transient component analysis method to analyze the corrected signal, that is, first construct the parametric periodic transient wavelet based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com