Forced broadsiding control method for rough rolling process in completely continuous hot rolling

A fully continuous and wide-spreading technology, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of small width specifications of continuous casting slabs and cannot cover product width specifications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0069] In the embodiment of the present invention, select rolling steel type: Q235B

[0070] The incoming material width is 380mm, the incoming material thickness is 165mm, the R5 exit thickness is 35mm, the R5 exit rolling speed is 2.0m / s, the target width is 500mm, and the target width thermal state value is 507.7mm. The rolling mill rigidity of R1~R5 is 3000kN / mm.

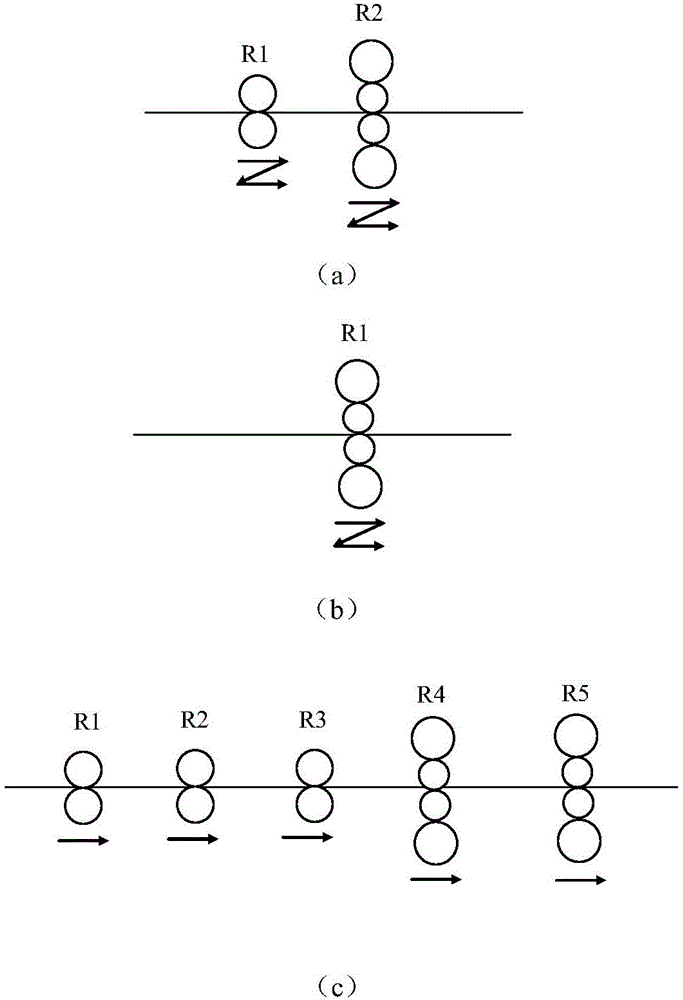

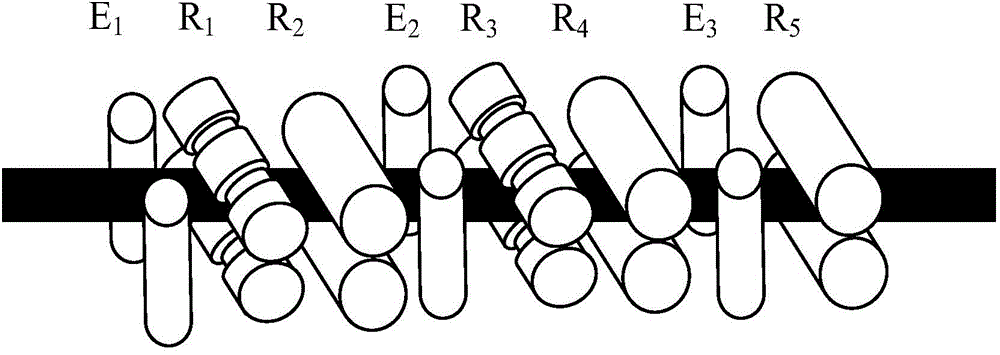

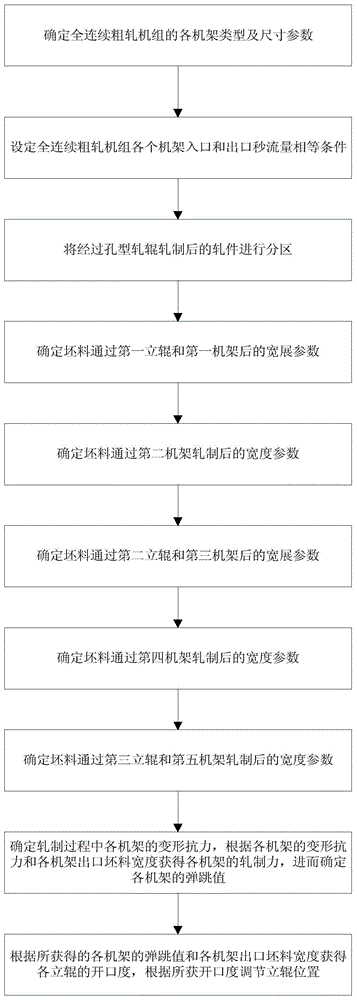

[0071] In the embodiment of the present invention, the forced widening control method of the rough rolling process in the full continuous hot rolling, such as figure 2 As shown, the method adopts a full continuous roughing mill, and the method flow chart is as follows image 3 shown, including the following steps:

[0072] Step 1. Determine the type and size parameters of each stand of the full continuous roughing mill, specifically:

[0073] Set the first stand R1 and the third sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com