Dual-spherical hard sealing type flue damper

A technology of spherical sealing and flue baffles, applied in lift valves, engine components, mechanical equipment, etc., to avoid excessive bearing temperature, solve poor sealing surface contact, and reduce heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, Features and functions are described in detail below.

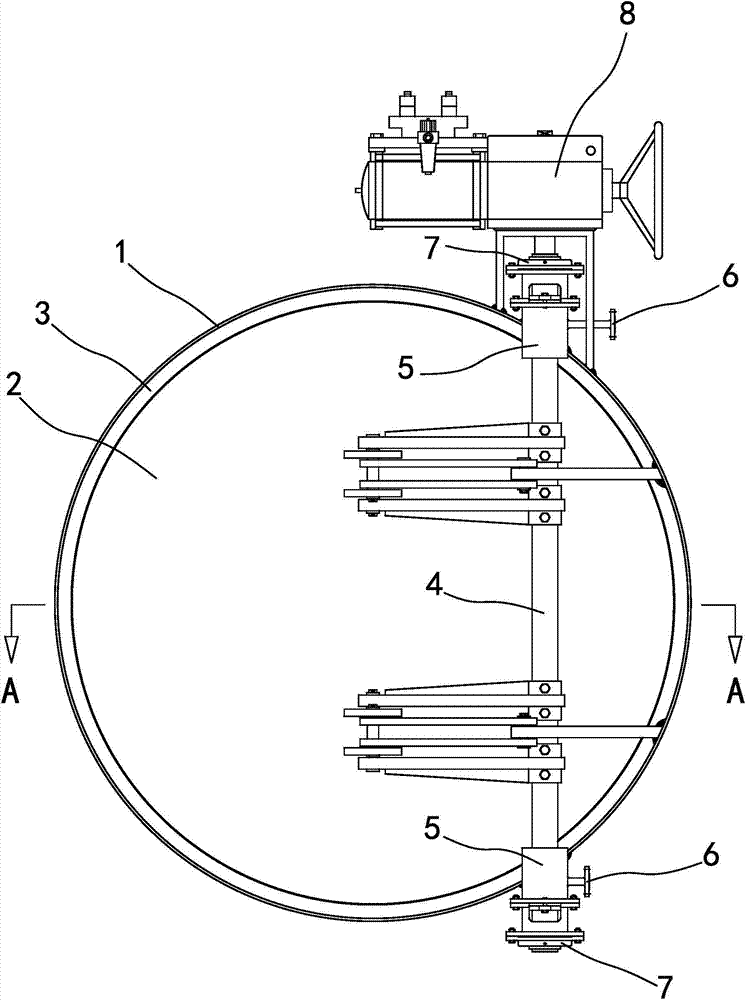

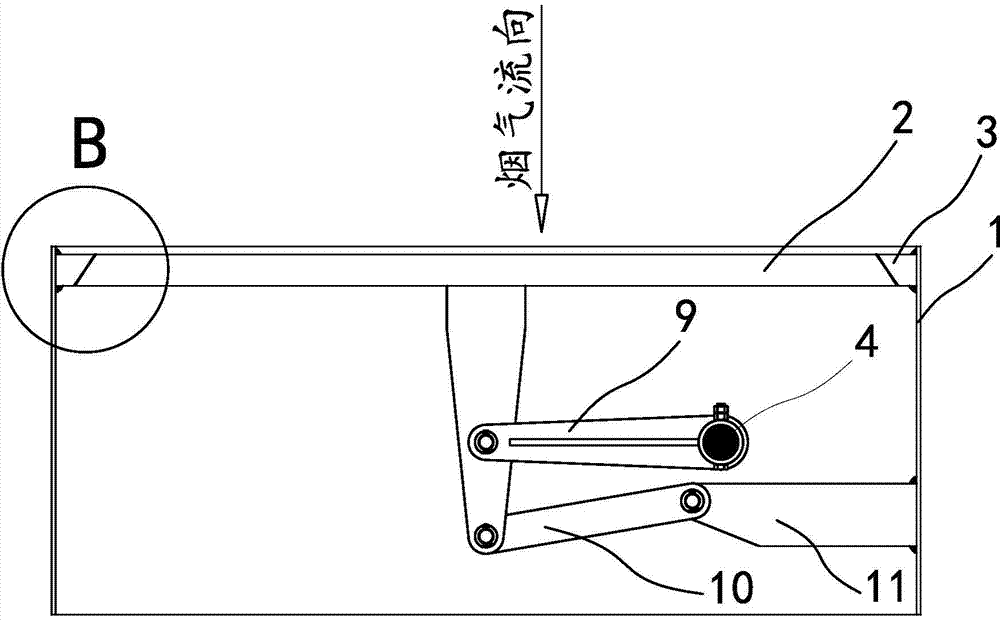

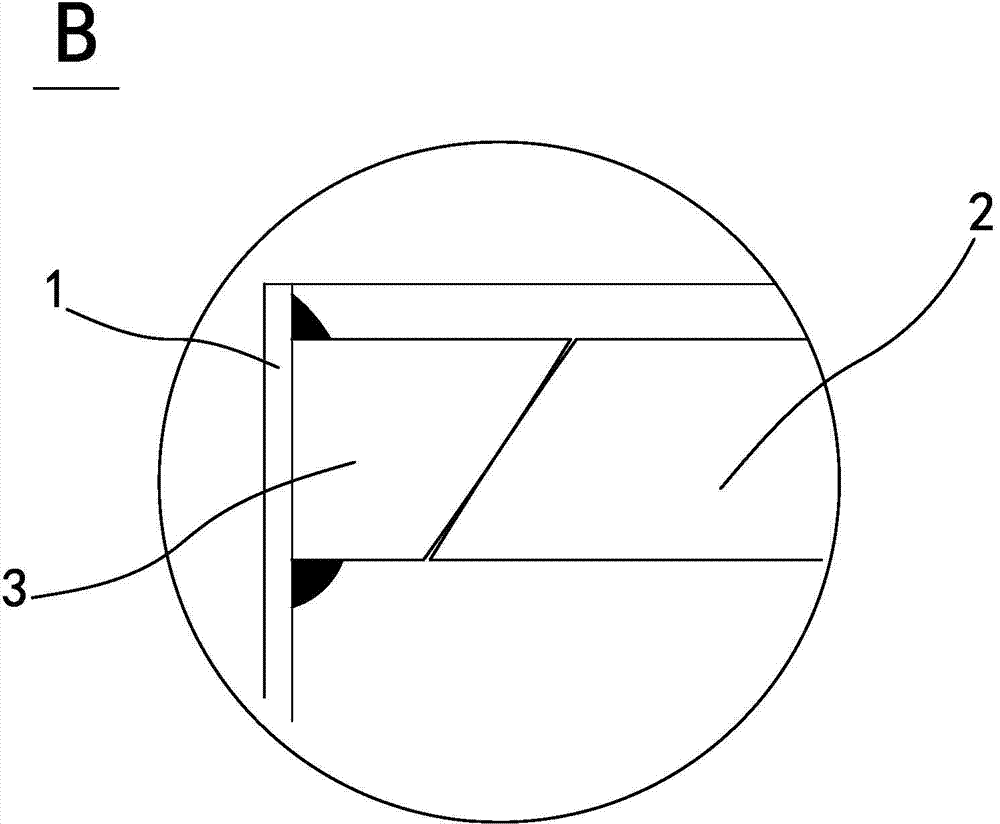

[0038] see figure 1 and figure 2 , a double-spherical hard-seal flue baffle of the present invention, including a spherical sealing valve plate 2, a spherical sealing body 3, a drive shaft 4, a stuffing box 5, a pneumatic actuator 8, and a support arm 11, wherein the pneumatic actuator 8 is welded on The casing 1 provides power for the rotation of the drive shaft 4 . Both ends of the drive shaft 4 are respectively provided with stuffing boxes 5 , and one end passes through the stuffing boxes 5 and is connected with the pneumatic actuator 8 . The stuffing box 5 is also welded on the casing 1, on the one hand, it is used to support the drive shaft 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com