High speed train totally enclosed type permanent magnetic traction motor

A traction motor, fully enclosed technology, applied in electric components, electromechanical devices, electrical components, etc., can solve the problems of poor cooling effect of fully enclosed permanent magnet motors, inability to control the uniform temperature rise inside the motor, and avoid excessive bearing temperature. High, avoid the effect of excessive temperature rise or uneven temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

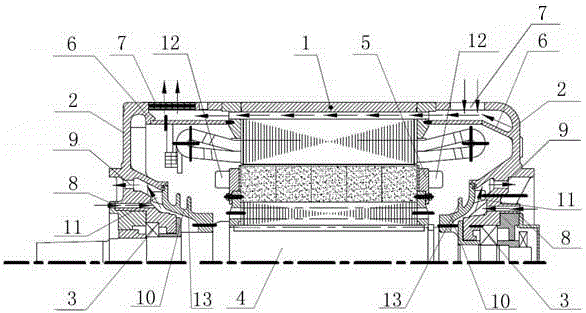

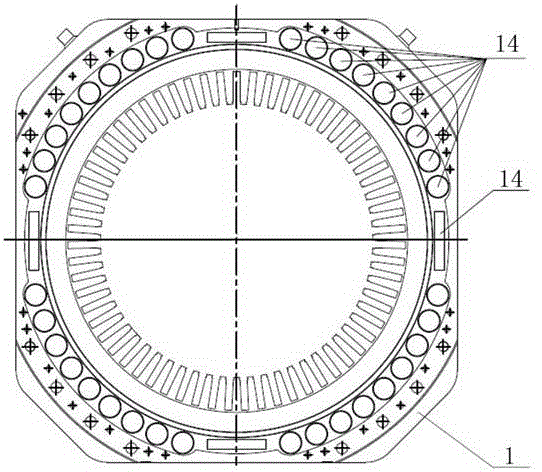

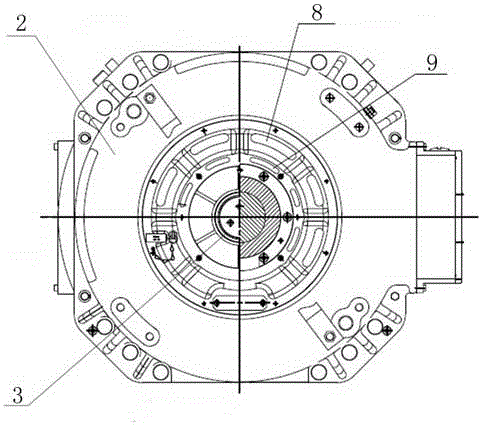

[0015] Fully enclosed permanent magnet traction motor for high-speed train, including frame 1, end cover 2, bearing 3, rotating shaft 4, permanent magnet baffle press ring 5; the frame 1 is welded by punching sheet, pressing plate, end plate, and drawing plate The pressing plate, the punching piece, and the end plate are symmetrically opened along the center of the rotating shaft 4 with multiple sets of base ventilation holes 14 axially arranged along the rotating shaft 4; the end cover 2 is provided with a ring-shaped inner wind cylinder 6, The inner air cylinder 6 is in sealed connection with the machine base 1, and the end cover 2 is provided with a plurality of end cover ventilation holes 7 distributed along the circumference of the shaft 4 in the radial direction. The end cover 2, the inner air cylinder 6, the machine The seat ventilation holes 14 are enclosed to form a machine seat cooling air path; the end cover 2 is provided with centrally symmetrically distributed beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com