Frequency conversion multi-connected type heat pump system and control method of bypass electronic expansion valve

An electronic expansion valve, heat pump system technology, applied in heating and cooling combination, refrigerator, refrigeration components, etc., can solve the problem of heat pump system not running normally, thermal comfort characteristics, system energy efficiency reduction, damage to compressors, etc., to achieve real-time Adjustment control, good thermal comfort characteristics, good effect of safe and stable operation of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

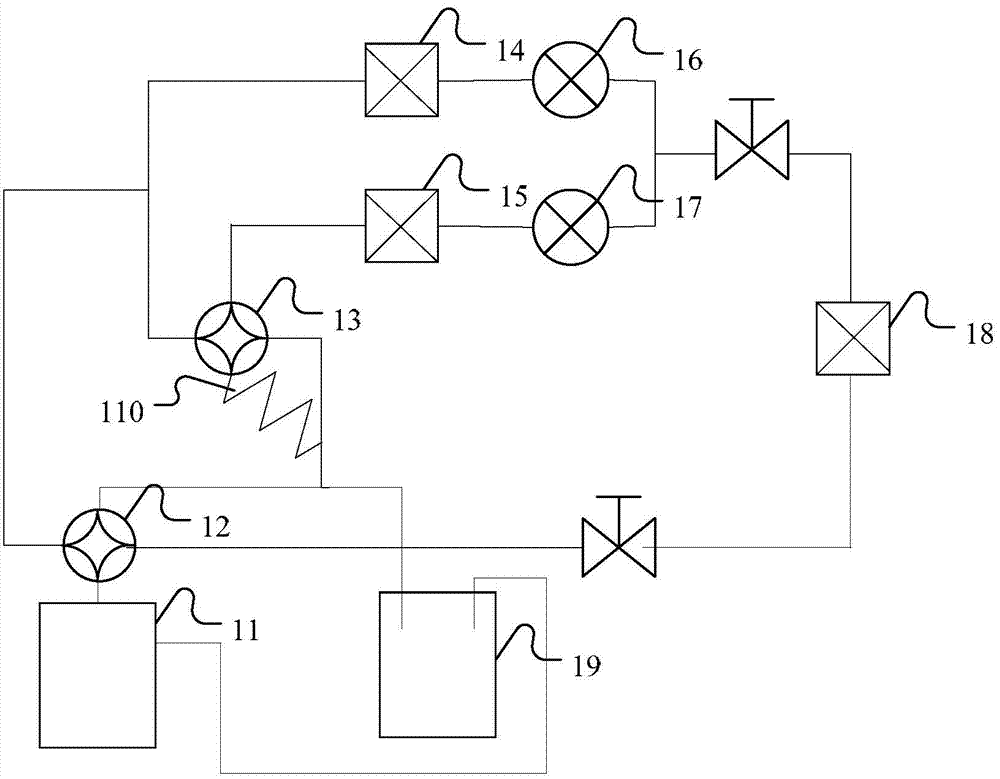

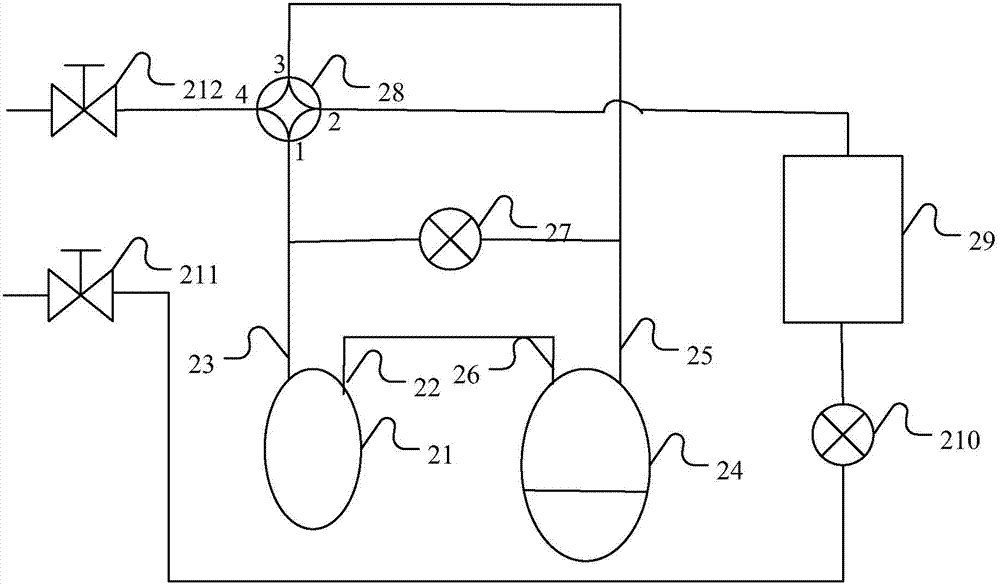

[0027] Such as image 3 As shown, it is a schematic structural diagram of an embodiment of a frequency conversion multi-connected heat pump system provided by the present invention, specifically including: a gas-liquid separator 21 , a compressor 24 , a bypass electronic expansion valve 27 and a four-way reversing valve 28 .

[0028] The inlet end 23 of gas-liquid separator 21 is connected with the first port 1 of four-way reversing valve 28; 25 is connected to the third port 3 of the four-way reversing valve 28; one end of the bypass electronic expansion valve 27 is connected to the exhaust port 25 of the compressor 24, and the other end is connected to the inlet port 23 of the gas-liquid separator 21 for The refrigerant output from the compressor 24 is throttled by adjusting its own opening.

[0029] Preferably, an outdoor heat exchanger 29, an outdoor electronic expansion valve 210, a liquid side stop valve 211 and a gas side stop valve 212 may also be included,

[0030] ...

Embodiment 2

[0041] On the basis of the systems described in Embodiment 1 and Embodiment 2 above, the present invention provides a control method for the system. details as follows:

[0042] When the system is in the cooling start-up phase, if the detection knows the suction pressure P of the compressor S is less than or equal to the first threshold, the opening of the bypass electronic expansion valve is controlled to be 100%; if the suction pressure P of the compressor S If it is greater than the first threshold, the opening of the bypass electronic expansion valve is controlled to be 0%; specifically, the first threshold can be set to 0.11Mpa, but it is not limited thereto.

[0043] When the system is in the heating start-up phase, if any of the following conditions is met, the opening of the bypass electronic expansion valve is controlled to 100%; if none of the following conditions are met, the opening of the bypass electronic expansion valve is controlled is 0%; the conditions incl...

Embodiment 3

[0051] A specific embodiment is given below to describe the control method of the above-mentioned variable frequency multi-connected heat pump system in detail.

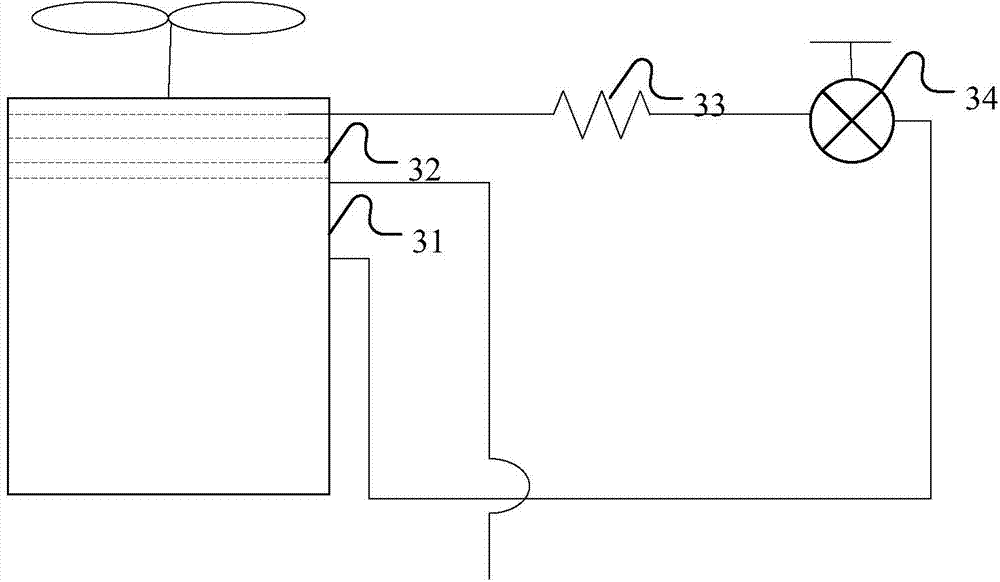

[0052] Such as Figure 4 As shown, it is a schematic flow chart of an embodiment of the control method of the frequency conversion multi-connected heat pump system provided by the present invention, specifically including:

[0053] When it is determined that the four-way reversing valve is in the power-off state, the second port of the four-way reversing valve is connected to the third port, and the first port is connected to the fourth port, and the system is in the cooling startup stage. The cooling start time is within 9 minutes or the discharge temperature Td<90°C. In the cooling start-up phase, when the suction pressure Ps≦0.11MPa, the opening of the bypass electronic expansion valve is controlled to 100% (full open), so that the refrigerant discharged from the compressor returns to the gas-liquid separation th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com