The valve of the suction head of the vacuum cleaner

A vacuum cleaner, valve technology, applied in the direction of vacuum cleaners, nozzles, cleaning equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

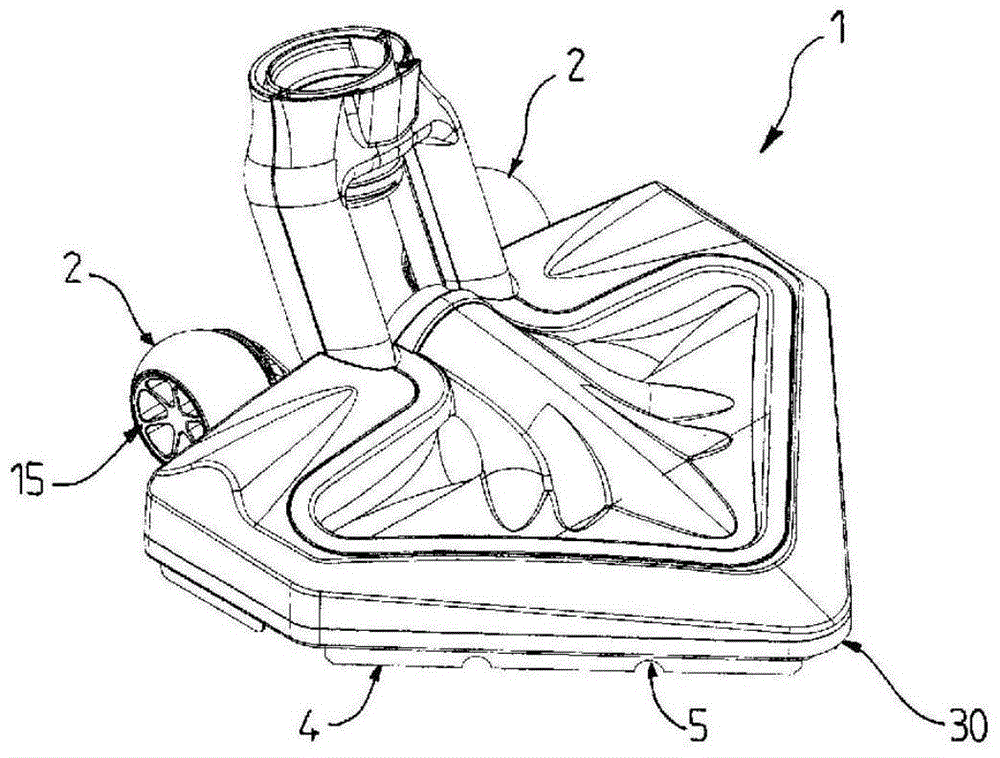

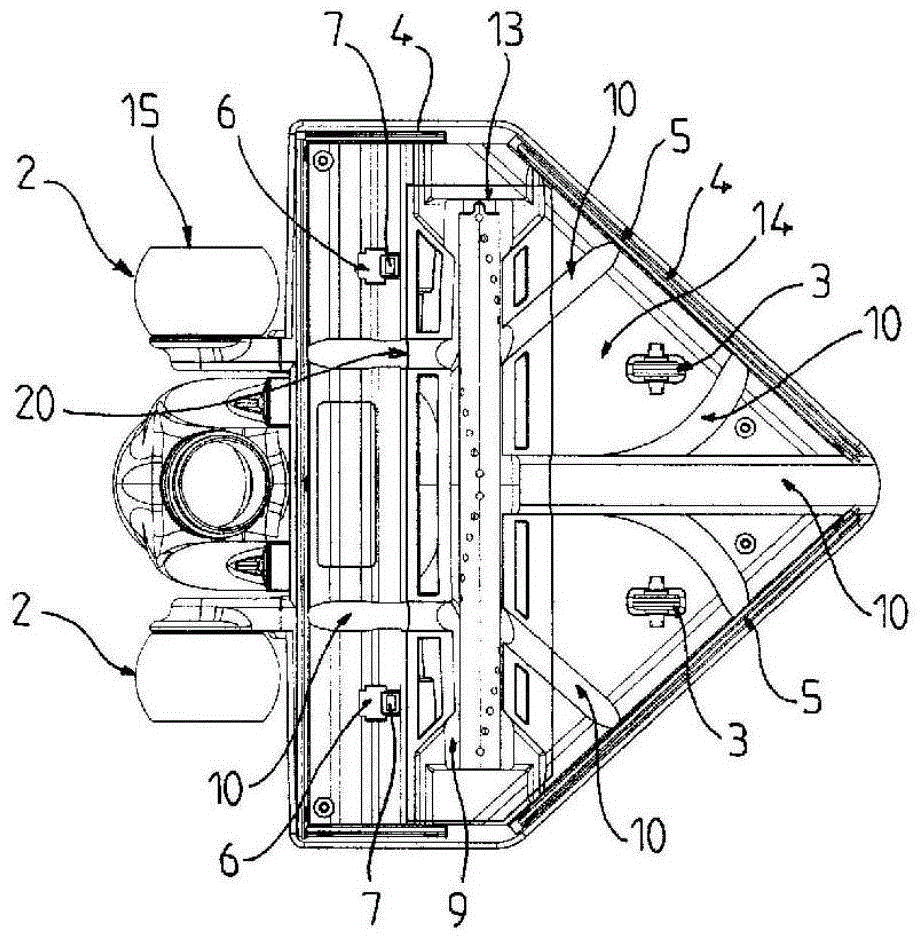

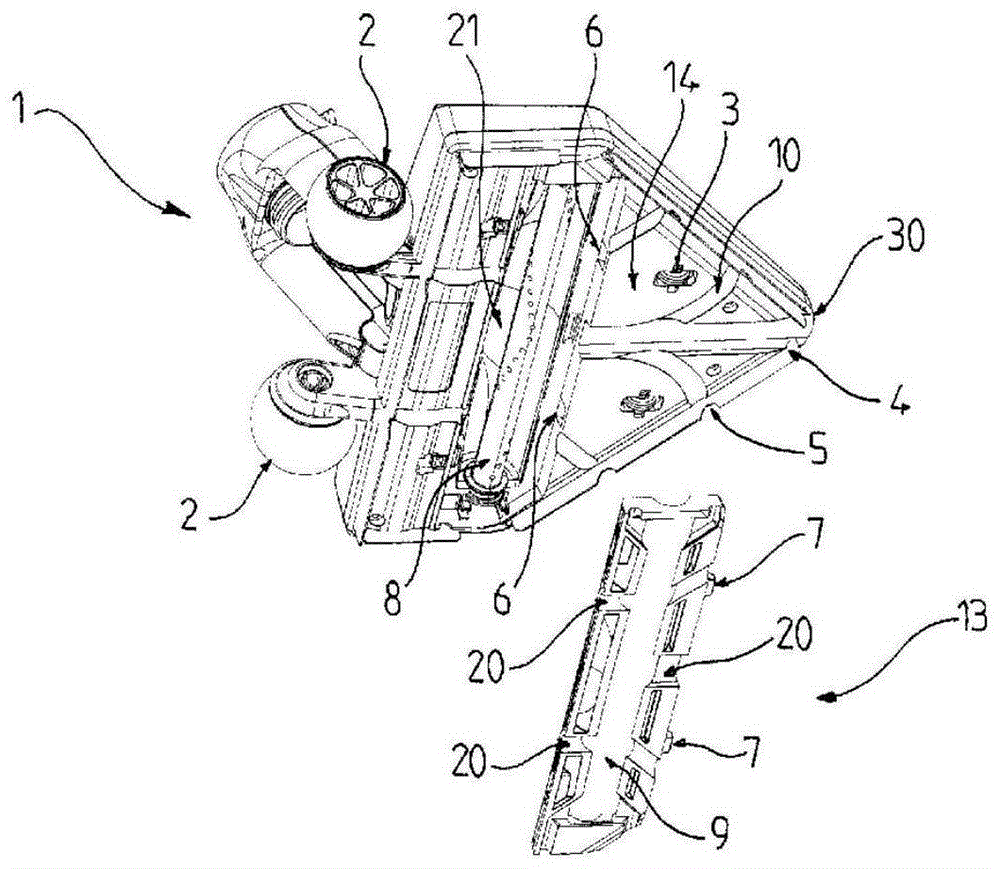

[0020] figure 1 Shown is a suction head 1 for a vacuum cleaner comprising a base 14 and a wheel 2 whose rolling belt 15 is shaped in the form of a roller and which defines the minimum distance from the base 14 when the suction head 1 is placed on a slippery floor. ground distance. At least two small wheels 3 are also arranged below the base 14 . The suction head 1 has a triangular overall shape, and the tip 30 of the triangle is positioned in the direction of movement of the suction head 1 .

[0021] In a particular embodiment, a sealing lip or sealing skirt 4 is arranged around the seat 14 . The sealing skirt 4 eliminates leakage between the smooth ground and the base 14, and for good suction efficiency, the sealing skirt 4 is perforated opposite the duct 10 of the base 14 so that it is sucked under the base 14 The air only enters directly into the duct 10 of the base 14. This results in a good suction of dirt from the floor since the air velocity is greatest in the duct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com