Glass adhesive tape appearance tester

Appearance inspection and film technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of rough detection and inability to detect, and achieve the effect of improving convenience, eliminating defects, and simple and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

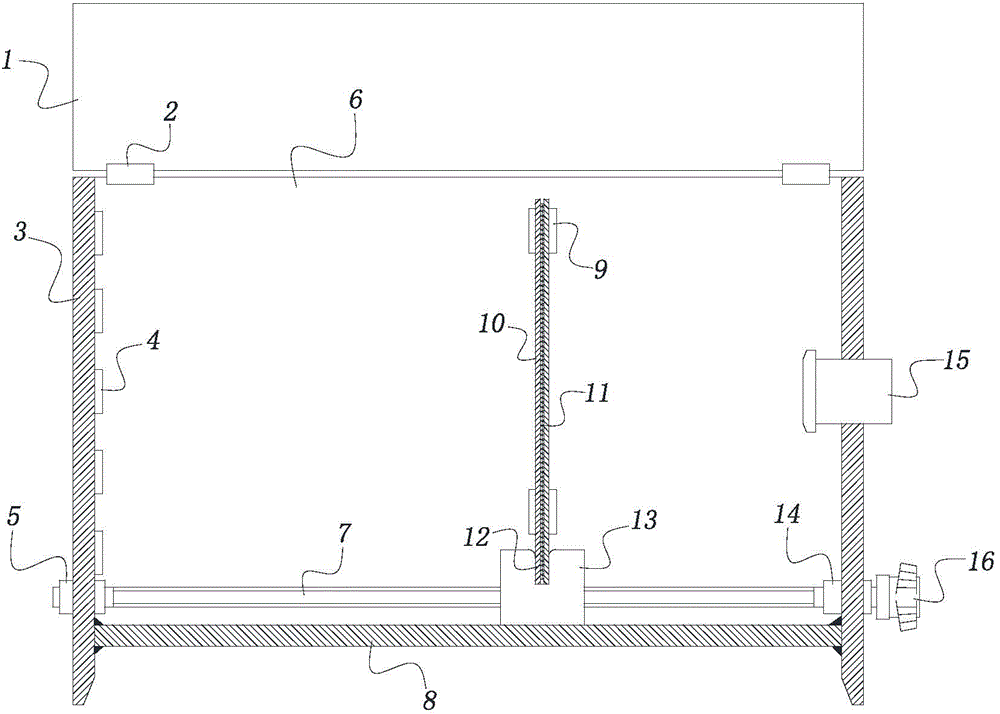

[0010] See figure 1 , the present invention comprises a box body 6 with an open top and a cover plate 1 buckled on the top of the box body 6 , the cover plate 1 is connected to the top edge of one of the side walls 3 of the box body 6 by a hinge 2 . The box body 6 and the cover plate 1 provide an isolated detection environment, avoiding the influence of external light on the detection result.

[0011] A plurality of light sources 4 are arranged on the inner surface of the left side wall 3 of the casing 6 , and a horizontal eyepiece tube 15 with an eyepiece lens is installed in the middle of the right side wall 3 of the casing 6 . In this embodiment, the eyepiece lens is selected as a convex lens.

[0012] A horizontal first sleeve 5 is provided at the bottom of the left side wall 3 of the box bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com