Continuous beam type anti-floating structure of shield tunnel

A shield tunnel and beam-type technology, which is applied in tunnels, infrastructure engineering, protection devices, etc., can solve the problems of small buoyancy resistance, increased tunnel pressure, and high cost, so as to improve the buoyancy resistance, good buoyancy resistance, The effect of reducing the amount of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

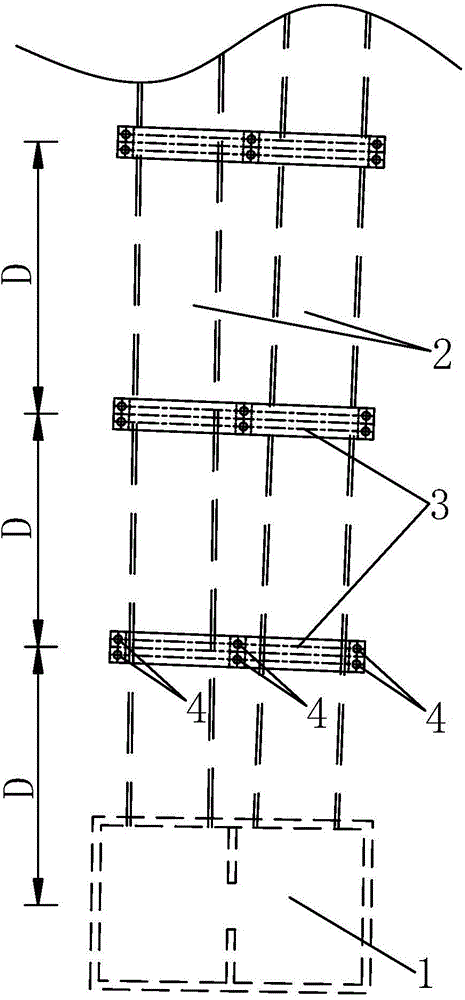

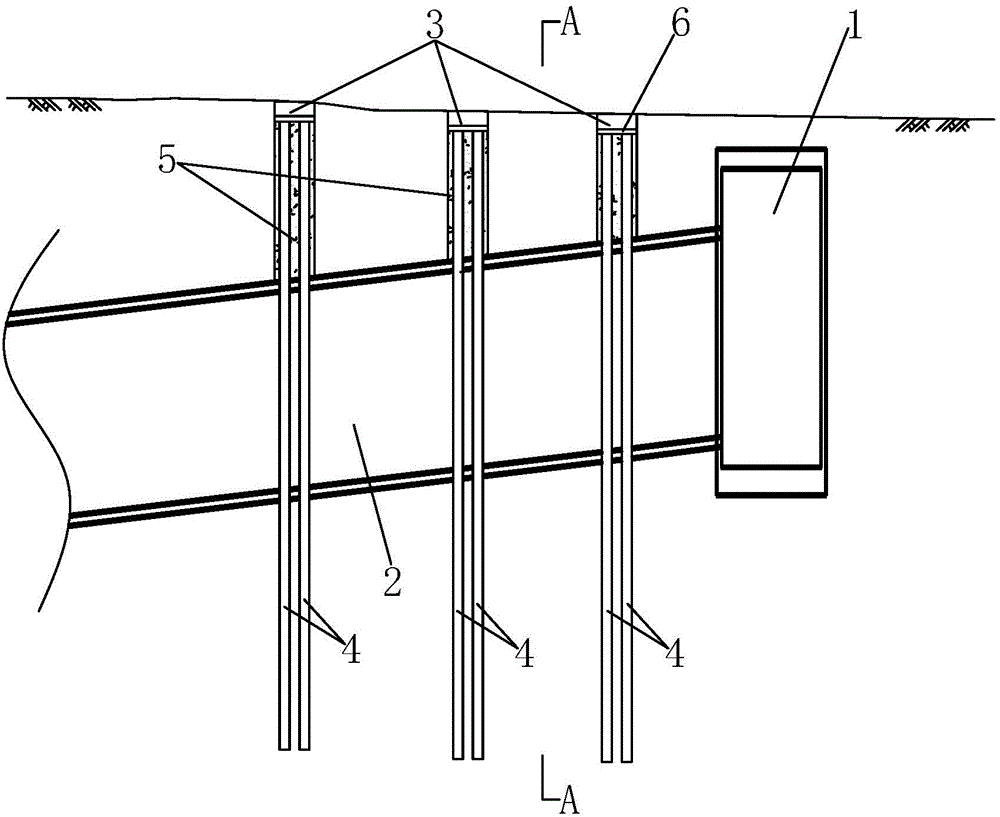

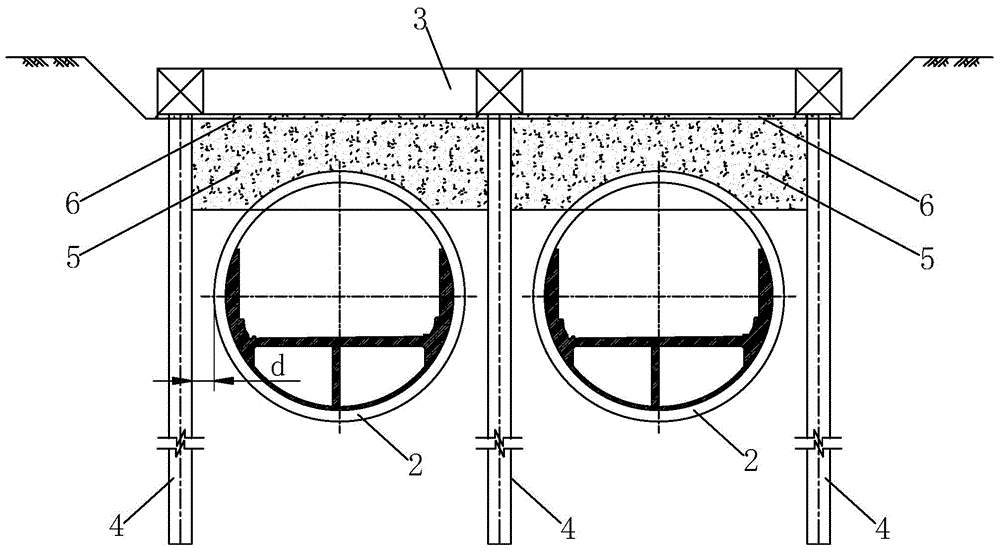

[0046] Example: such as figure 1 As shown, a shield tunnel continuous beam anti-floating structure provided in this embodiment includes several caps 3 arranged at intervals along the longitudinal direction of the shield tunnel 2, and all the caps 3 are arranged laterally on the shield tunnel 2 above, and the transverse centerlines of all the caps 3 are perpendicular to the vertical plane where the central axis of the shield tunnel 2 is; each of the caps 3 is provided with several sets of anti-corrosion Pulling piles 4, the number of groups of uplift piles 4 under the same cap 3 is the total number of shield tunnels 2 plus 1, and all groups of uplift piles 4 under the same cap 3 are respectively arranged in the corresponding The two sides of the shield tunnel 2, and two adjacent shield tunnels 2 share a group of uplift piles 4, the number of uplift piles 4 in each group of uplift piles 4 is at least 1, and each group of uplift piles The uplift piles 4 in 4 are also longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com