Turn limited wheel lug nut and nut cap

一种螺母盖、轮爪螺的技术,应用在螺母、车轮、轮盖盘等方向,能够解决昂贵、安装和/或移除困难、昂贵轮爪螺母制造工艺等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

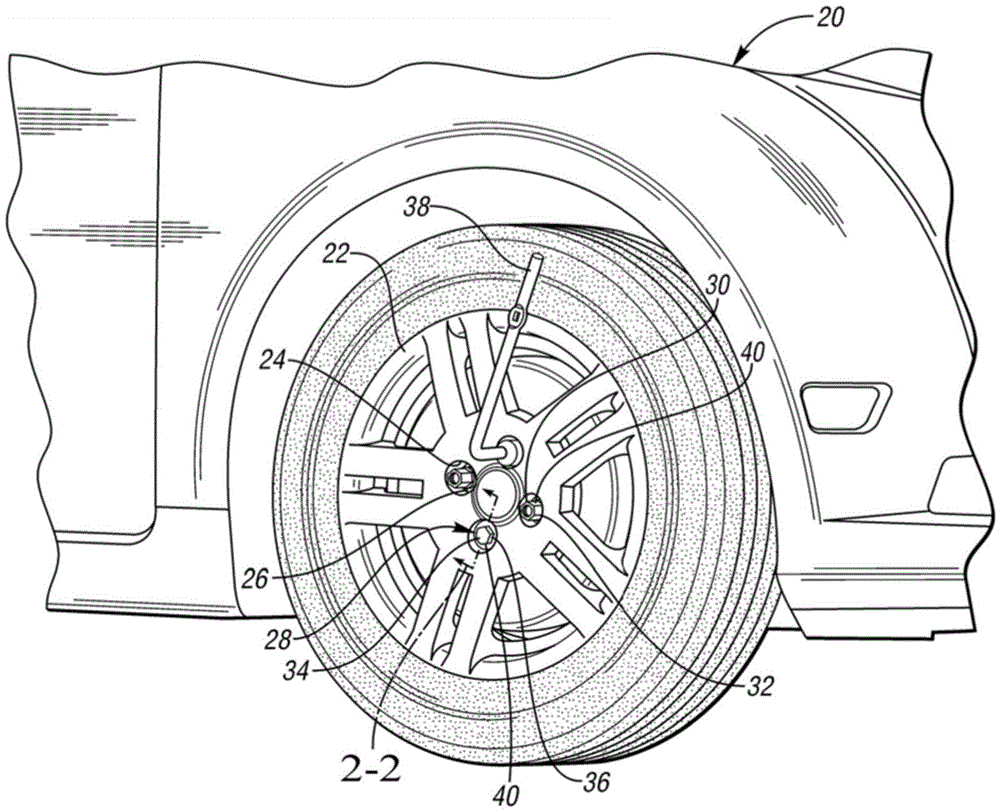

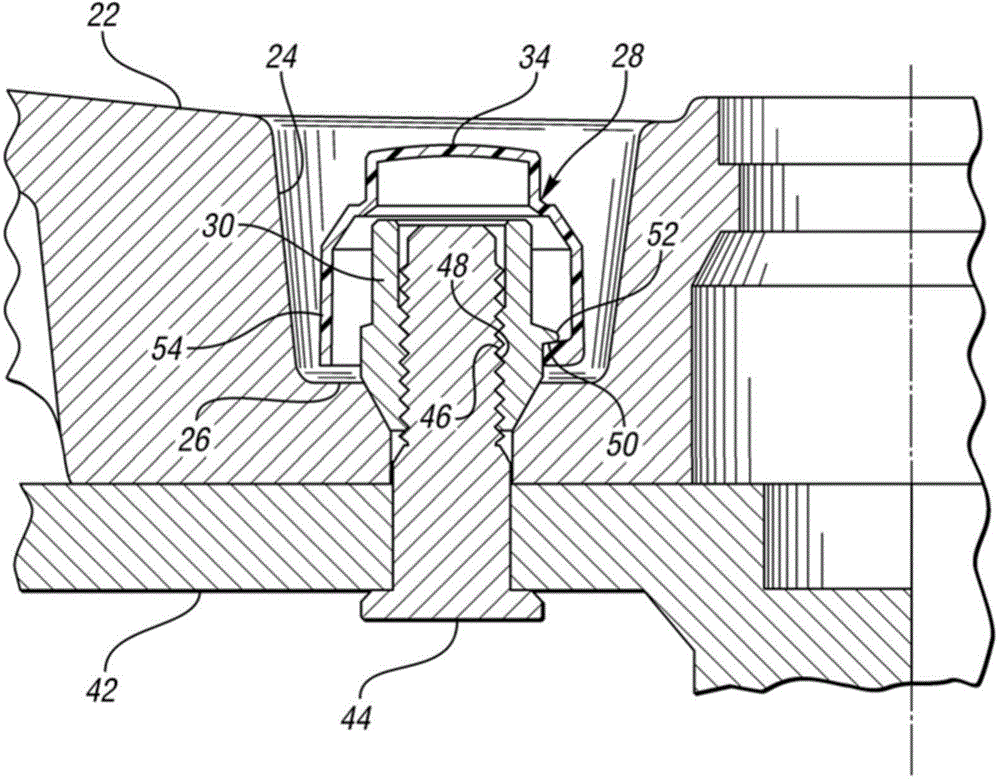

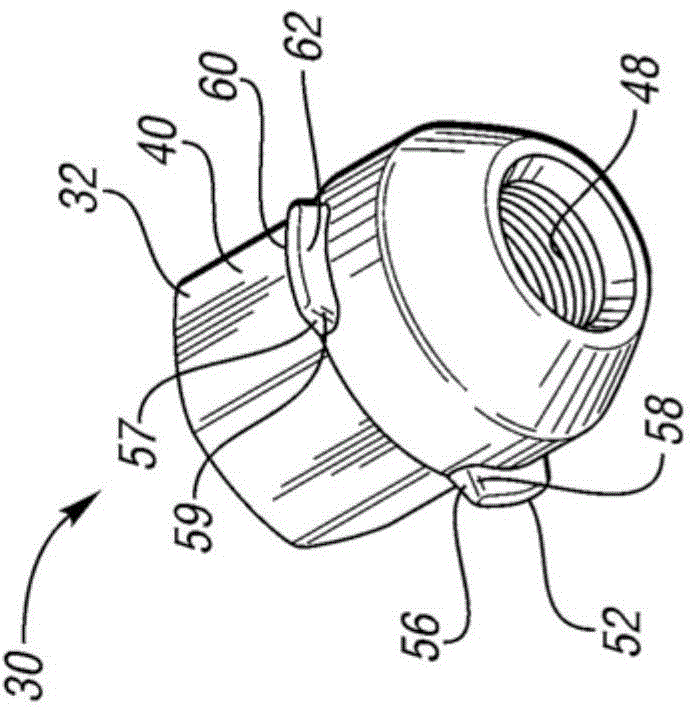

[0042] Referring to the drawings, wherein like reference numerals refer to like parts throughout the views, figure 1 A first embodiment of a rotationally limited lug nut and nut cover combination 28 is shown. Vehicle 20 includes wheels 22 . Vehicle 20 may be any type of car, truck, sport utility vehicle, or any other type of wheeled vehicle. Wheel 22 may be made of alloy, steel, or any other suitable material of construction. The wheels 22 are held on the vehicle 20 by lug nuts 30 . The lug nut 30 may be made of alloy, steel, or any other suitable material of construction. The wheel 22 may include a lug nut hole 24 formed or machined in the wheel 22 that may provide clearance for the lug nut 30 and a tool 38 for installation and removal of the lug nut 30 . The wheel 22 also includes a lug nut hole base 26 where a lug nut 30 retains the wheel 22 to the vehicle 20 . The gob nut 30 includes a first tool rotatable arrangement 32 . The first tool rotatable configuration 32 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com